Hey yall, not really sure I am phrasing this question correctly but… when I am cutting on mu shapeoko 3 xxl at the far right side my machine will alter the path it takes from the first pass to the second. It will maintain the path on all following passes. If after the job is finished and the machine sends itself to the far back I hit start again the machine will follow the second path without issue. It does this with imported files as well as stock files. Not really sure what us going on. It doesn’t appear to be slamming or skipping. Any help would be greatly appreciated

Post the .c2d file, generated G-Code, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes and a photo showing an attempt at cutting still in place on the machine and we will do our best to sort this out with you.

Thanks William,

my stock securing method is much like many other entry level guys i use painters tape and super glue. I put 1 strip of tape the full width of the stock every 3 inchs. i match that on my waste board and apply a heathly amont of glue. i then put weight on the stock. usually a few dumbbells or paint cans what ever is close. i let the glue set for about 10 minutes. i zero the machine once after inilazation and then once in the lower left corner of the stock. if the project has tool changes i put a dot of sharpie on the spot i am using as zero and zero there following all tool changes. i only have a problem if i am cutting to the far right. at least i havent incountered this anywhere else on the table. i made the attached test after i messed up a couple of cutting boards and relized it was only the ones on the right side.

for the test i didnt care to much about doing a perfect size match for the font i just wanted some curves and straight lines near each other. thanks again for all the help.

test sign.c2d (54.7 KB)

testsign.nc (37.5 KB)

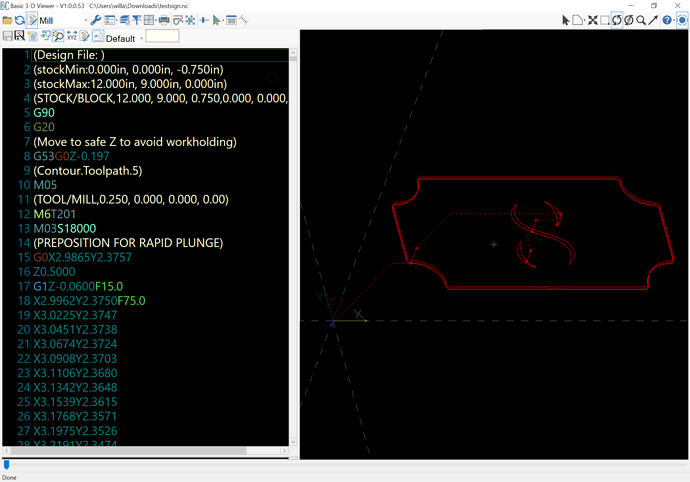

Not seeing anything in the file:

If the machine is mechanically sound per: Machine operating checklist

I would recommend adding geometry and cutting as a pocket to the penultimate pass or to tab depth so as to reduce tooling engagement:

Thanks for your quick responce. the part that confuses me is the fact that the machine only changes its course from the first pass to the second pass. it is consistant from there to the completion of the project. in my brain that would rule out tooling deflection… i might be missing the meaning of your suggestion… i am pretty new to this side of woodwork… sorry for the super noob thought processes here

It sounds as though it skipped steps. It’s it going far enough back it’s running out of travel, hitting an end plate, then continuing on that second path?

Hi @Mcwitsell,

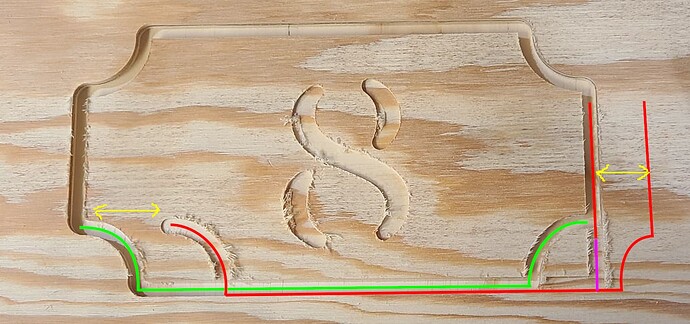

So here’s my take on this:

The red path is your first pass. Or rather what it should have been. But while travelling to the right to do the second rounded corner, it hit a limit (probably a travel/mechanical limit), so instead of doing that curve, it must have gotten stuck along X and only do the Y moves, resulting in the purple line, and from there everything subsequent to that will be shifted by the yellow distance.

You could manually jog to what that vertical red line on the right is, see if you are at the mechanical limit of the machine. You may not even be able to jog so far right, there are limits in CM during jogging…

Julien, I think you are correct. I didn’t think about the outer limits of the machine. I went out to the shop and jogged the machine to the far right and up to the front were the test piece is still secured and the max travel is were the purple line is. I’m gonna jog the machine with the router on to make a faint line at the max travels so I don’t mess this up again. Thanks everyone for the support you folks are awesome

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.