Hello all, 1st timer here, thanks so much in advance!

I got my XL 4 months ago and still have not had a successful cut  . I did have to stop trying/fiddling during the holidays so I could fulfill my orders, so it has not been a solid 4 months of frustrations.

. I did have to stop trying/fiddling during the holidays so I could fulfill my orders, so it has not been a solid 4 months of frustrations.

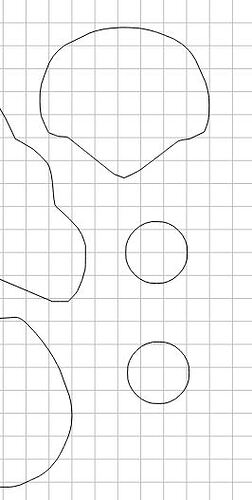

I am trying to use the machine in what I believe is its most basic task. I just want to cut out basic shapes. I make animal-shaped boxes and have been doing it all by hand, but with product demand, I got this XL to assist me. Here are some of my boxes. Just simple basic shapes:

or check out my website: beastieboxes.com

I have been in communication with the Carbide staff and they have helped me some, but I am still stumbling, and thinking this is supposed to be a precision machine, I shouldn’t be having so much trouble. Hopefully some of you can guide me in the right direction? I would really appreciate it!

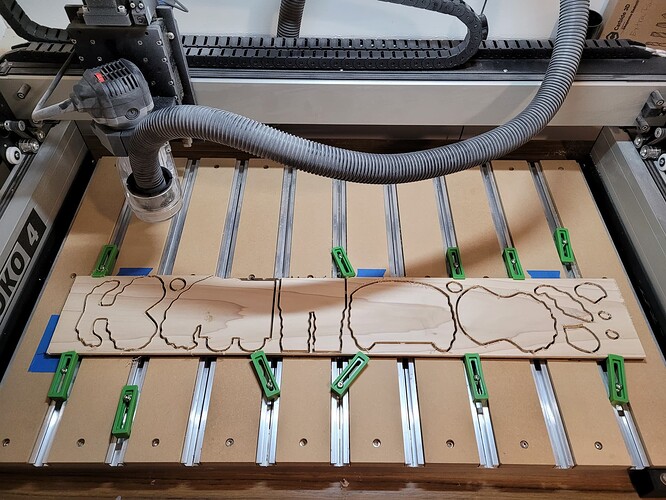

My main problem currently is that I am getting consistently wonky shapes (same ugly shapes made over and over) and the edges are far from smooth (CNC does 3 passes). Please see pics: the 2 ovals 'eye’s are supposed to be matching perfect circles. The ‘nose’ above it should be symmetrical. The fuzzy edges speak for them selves.

I have tried making the files in different ways. But I start with scanned hand-drawn stencils:

Then I use Photoshop (I know Illustrator would be better, but I don’ t have it. If I need it, I will get it, please advise) to layout the shapes & then create paths. Then I use an online converter to make SVG files, & send to the CNC. I have also tried importing the file into Carbide Create to trace the image, and I get the same results. The files I send to the CNC look good to my eye?

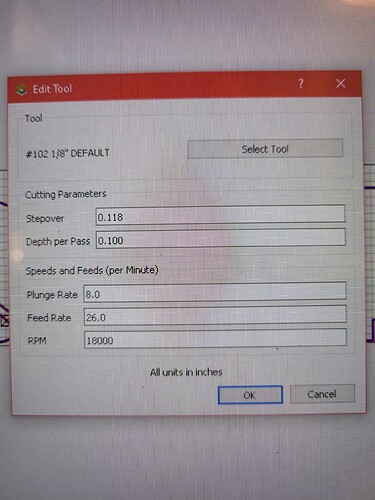

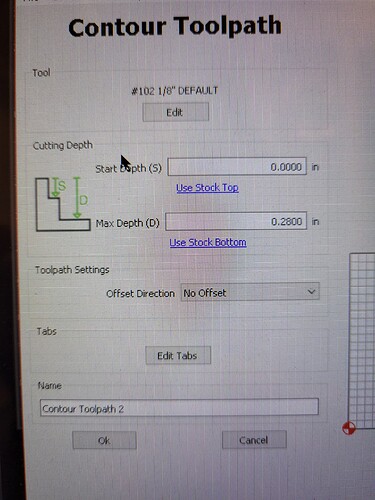

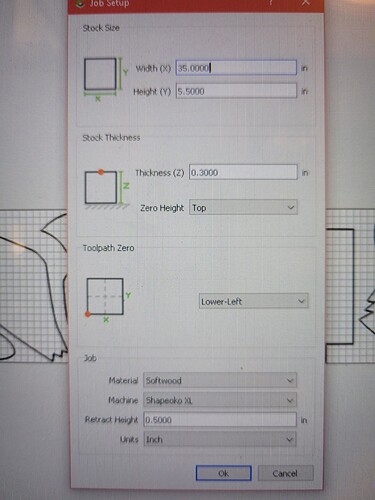

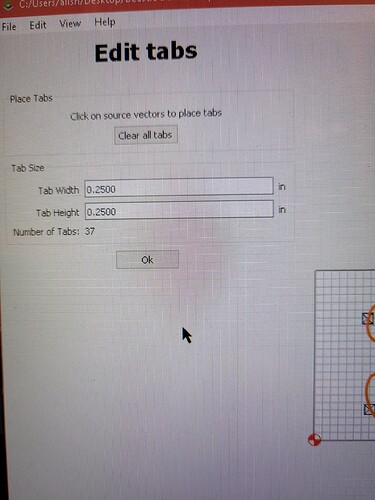

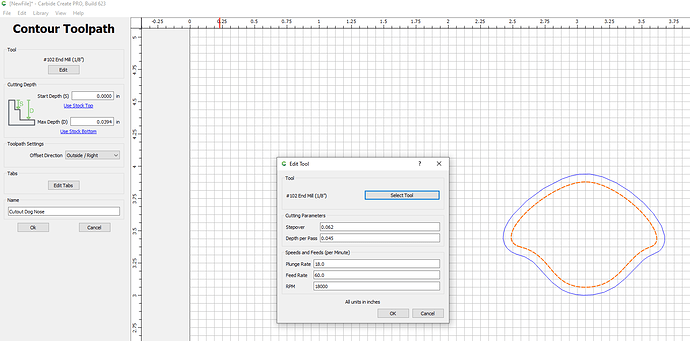

I am using soft 1/4" aspen and poplar boards. Here are pics of the parameters I have plugged into the CNC:

I recently got the #112 .0625" Flat Cutter endmill to experiment with, but have not tried it yet.

I hope I am doing something really obviously silly and someone can point it out to me  I welcome any and all suggestions/comments. THANK YOU!!!

I welcome any and all suggestions/comments. THANK YOU!!!

-alisha