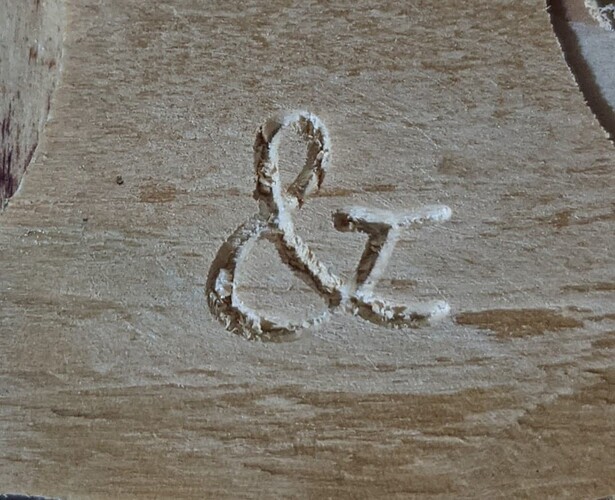

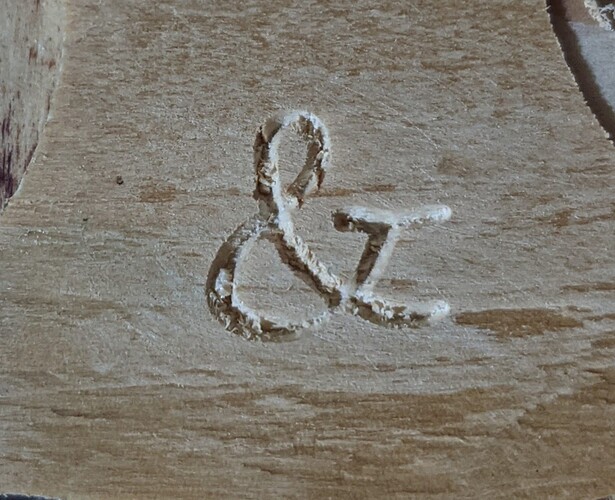

I am a newbie… When I use the V bit (60° or the 90°) at time the lettering needs to be sanded. If you take a look at the and sign, you can see the tool path is filled with attached debris. Any thoughts to how to remedies this? I am sure this is covered but I couldn’t find a thread on it.

Thanks!

Did you try re-running the toolpath a second time to clear out the slot?

Are you using dust extraction whilst cutting?

I did not rerun the path. I’ll try it.

I am using a sweepy dust boot. I am using plywood but I am not sure if that is a problem.

As Liam suggested run the project second time.

Plywood will work but had problems. The main problem is each ply is 90 degrees from the previous ply. The top veneer is usually thin. Many cabinet grade plywoods have voids in middle layers which can show up in project.

Baltic birch is better quality but is hard to get right now. Not all plywood is good quality. It looks good on the face but underneath may not be good.

I prefer solid wood but plywood is good if you choose wisely.

Recently I posted about baltic birch availability. Several suggested ecylyptus and appleply and a few others. Search on forum for ecylyptus and read replies.

Whenever possible use downcut bits. Vee bits are not made on downcut but any flat endmills try to use downcut.

Thank you for the responses! I had a few things wrong. Feeds and speeds were set for hardwood and not softwood. I ran it again on some Birch plywood that I had leftover and it looks much better. Thanks again!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.