Here is an update. First, thanks for the feedback Will and Dan.

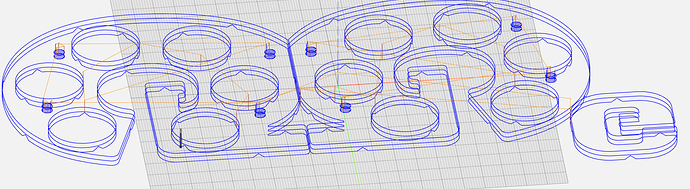

I’ve tightened belts. Aligned the router and holder to the spoilboard. Surfaced the spoilboard. Made sure the spindle and bit are at 90degrees. Updated Cut2D, which I use to make create my files. Plus, I made some simplifications to my cut files just to weed out any features that may cause this problem.

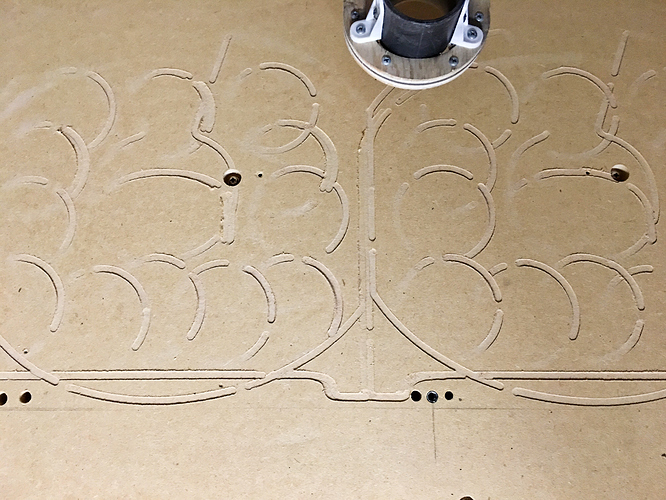

The result on my first test is seen in this photo:

Despite all of this work the problem I’m having did not resolve. I’ve attached a photo of my first test cut. What you see in the photo is all one job. It shows the letter G (2 of them facing opposite directions, then one small G bottom right), I drew pencil lines to represent portions of the job that did not cut through 100%. Notice how the circles are all the same. Half cut, half not 100% cut through. Same side on every circle. This is the same result I get with multiple files/jobs.

One small note: the side of each shape that does cut through 100% actually cuts into the spoilboard a bit. It’s as if the thing is cutting along a slightly skewed plane or something.

I added one change to this test. Normally, I select the outline of both G’s and cut them as one line item. The result is that the outline would not cut through on one side (the same side) of each G. In my test here, I assigned them separately. I also set up one as a “climb” cut and the other a “conventional” cut, somewhat per Will’s suggestion. The result is that for the first time the left and right G outline have a mirroring occurrence of the half cut, half not cut issue. Switching the cut direction had an impact, but did not resolve the issue. Very telling, though I don’t know what it’s telling me.

Even the small G, bottom right, has the left side cut through, right side not. And the cut through portion is literally touching part of the G that did not cut through 100%. That would not happen if the spindle and surface were not perpendicular. Heck, it won’t happen if they are perpendicular.

I have no idea what is causing this issue. It’s consistent. Climb or conventional changes the side that isn’t cut through 100%. I’m not sure if it’s the program making the cut files (Cut2D), the program running the operation (Carbide Motion), or some unaddressed aspect of the physical machine. Seems more digital at the moment, but I need someones help telling me exactly where to look.

Thank you!