I’ve decided to bite the bullet and upgrade to a water cooled spindle. I have a standard Shapeoko. Main reason is noise reduction. I am a hobbyist and not in need of speed or heavy use. I know that sound reduction can help, but you also have to cool the unit so that leaves an opening for the sound to get out.

Looking for an 800W 110V spindle. Aliexpress has them and I could get it in 2-3 weeks. But, they say to text them if you want 110 volt, which I did. Two days later and no response, doesn’t bode well for support if they don’t respond to a sales message. Have not found anyone in the US that stocks the 800W spindle and VFD combo.

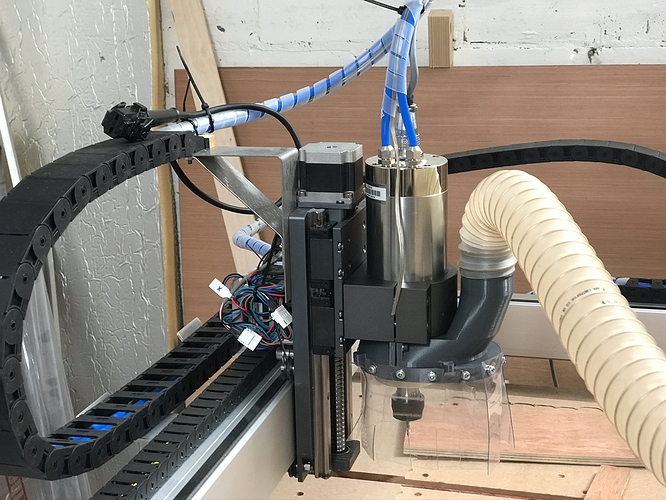

So looking for something that can arrive in a reasonable time ( I’m not patient ). Price and delivery wise I can go for a 1.5KW 110V spindle as they are more readily available. This would require changing the mounting bracket to 80MM. From the photo it looks like the bracket will have to be modified to fit on the standard Z plate, not a big deal I guess. The one I’m looking at is: https://www.ebay.com/itm/1-5KW-WATER-COOLED-KIT-SPINDLE-CNC-110V-SPINDLE-MOTOR-INVERTER-CLAMP-PUMP-PIPE-/274103480988?_trksid=p2349526.m4383.l4275.c10#viTabs_0

So what should I do