When testing with the new Carbide Motion, things happen a bit differently, but the result is the same.

Download 635 from:

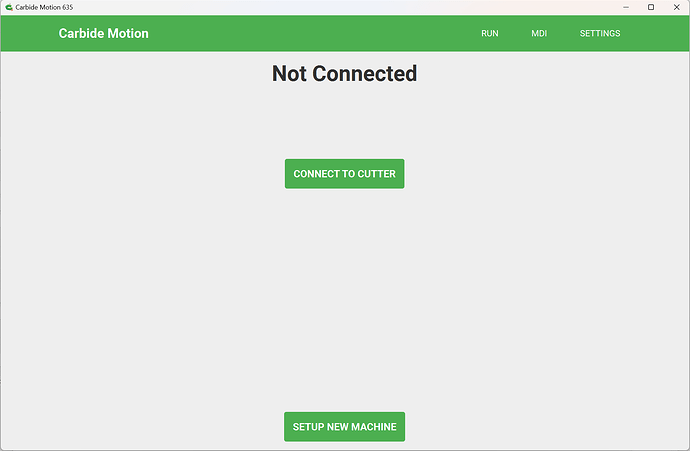

After installation, launch the program:

(if necessary, configure per: Shapeoko Machine Setup )

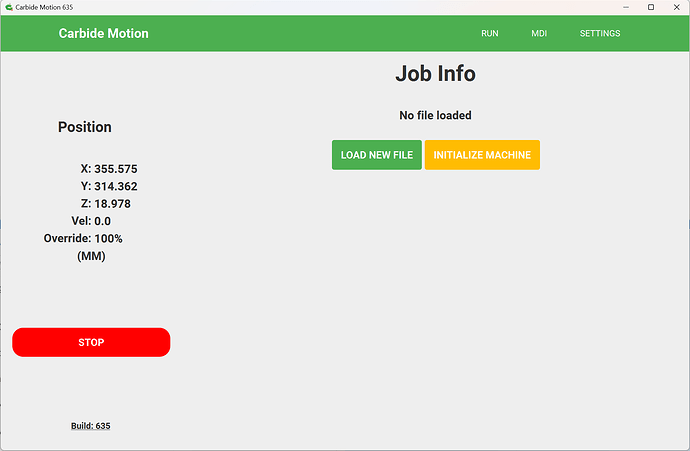

Connect:

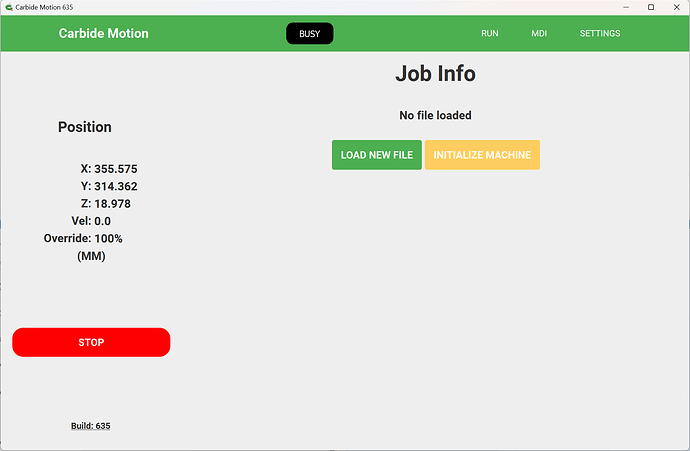

Initialize:

and the machine will initialize and then move to the front.

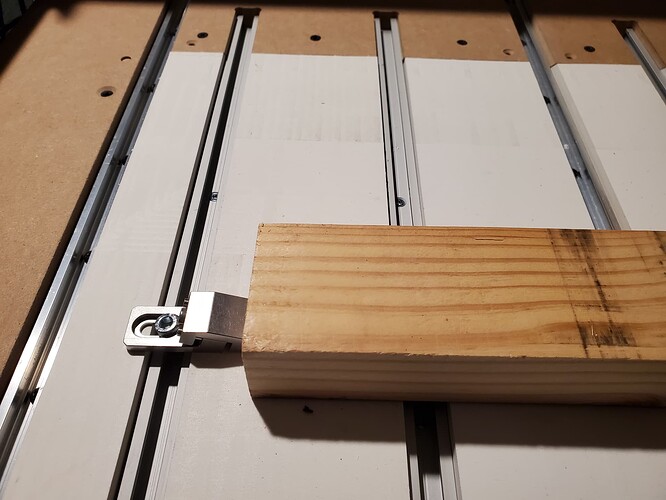

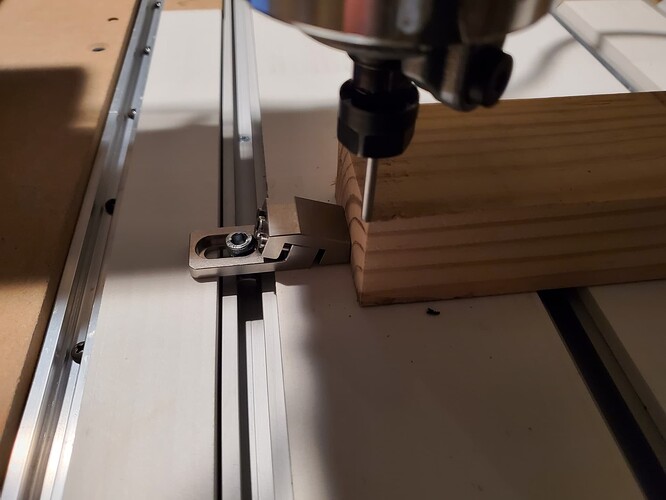

Clamp stock on the machine:

position the BitZero on it appropriately for the sort of probing which one wishes to do:

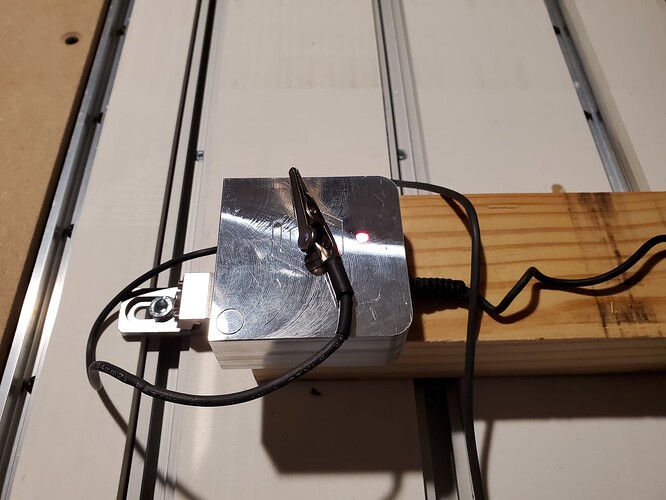

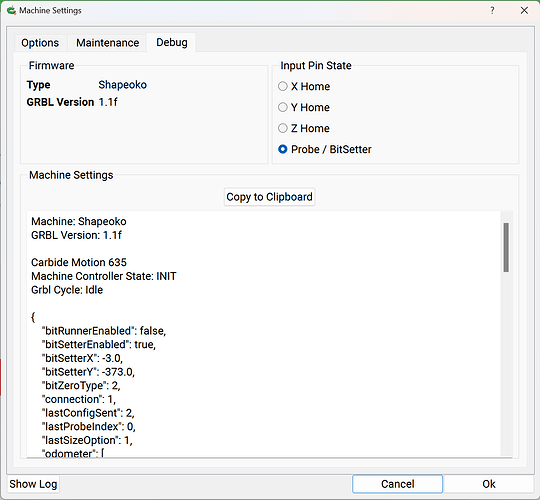

Verify that the ground lead creates a signal:

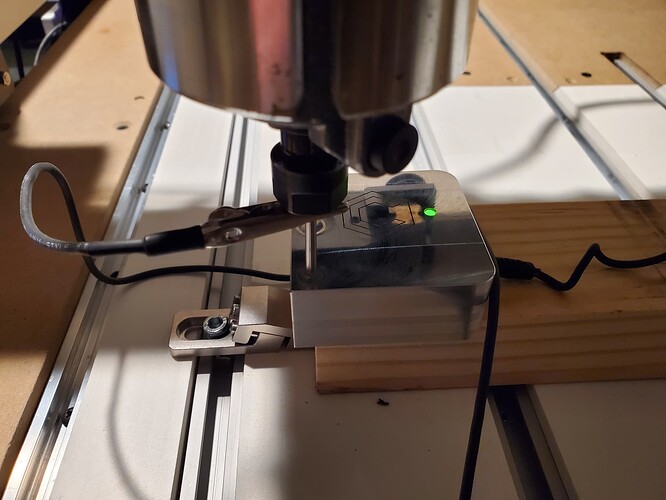

Install a probing pin and position the machine so that it is over the circle to begin a probe and clip on the ground lead:

and test that the ground lead works as expected by touching the probe to the tool (no photo — only have two hands)

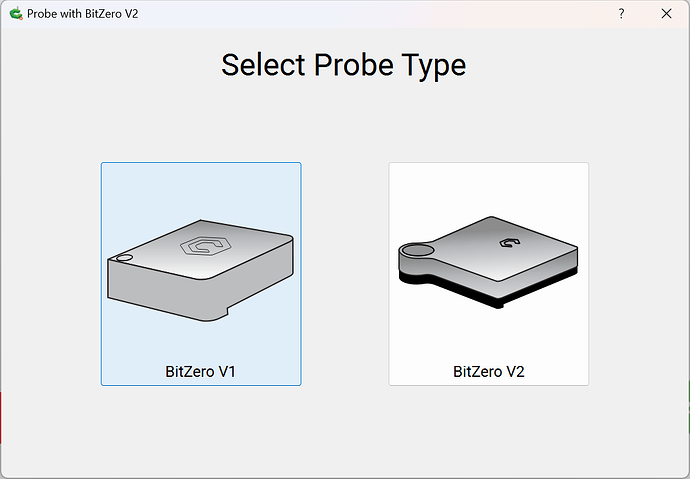

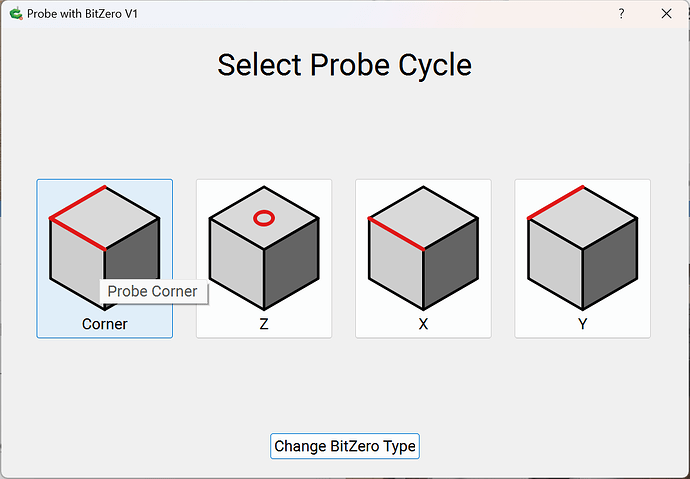

Then probe — if need be, choose the appropriate BitZero type:

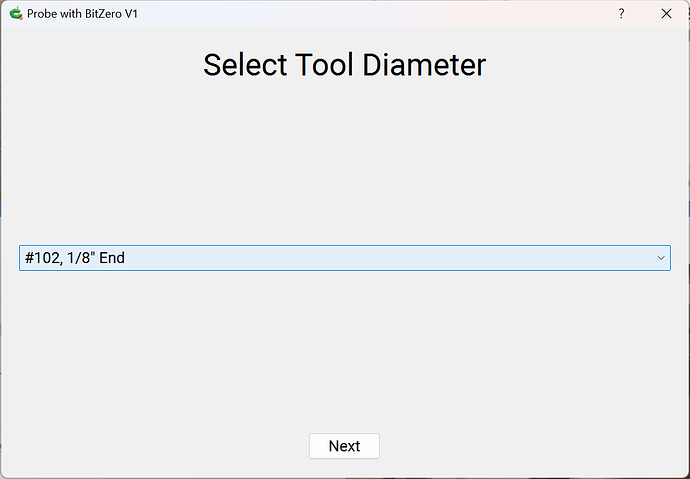

Select the correct tool:

Next

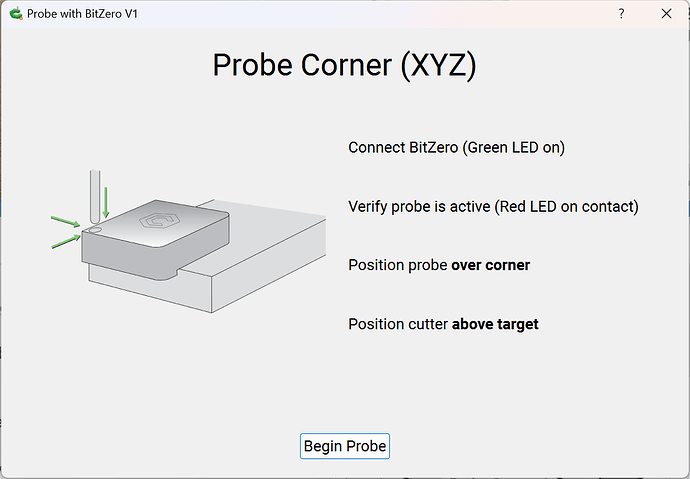

Begin Probe

The machine will:

- probe down to find Z

- lift, then move left, then down, then probe right to find X

- lift, move right, then forward, thend down, then probe towards the back of the machine to find Y

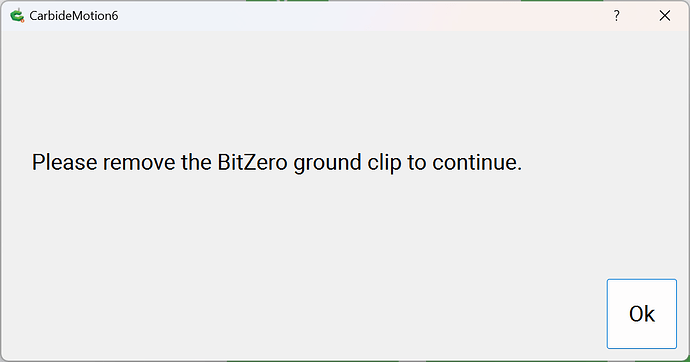

- lastly it will lift, move back and left and if the BitSetter is enabled will prompt:

Ok

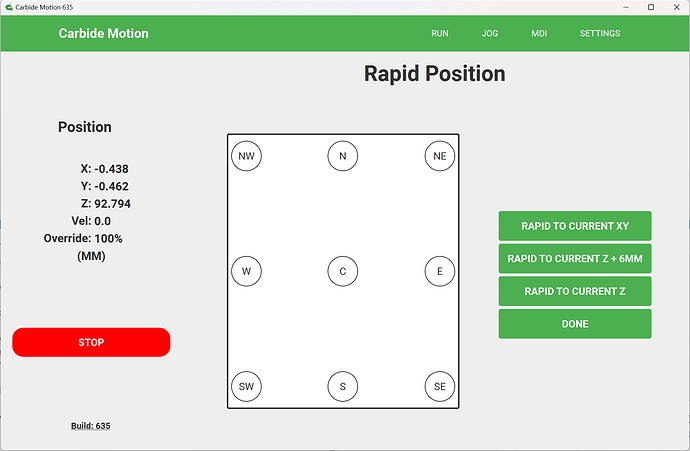

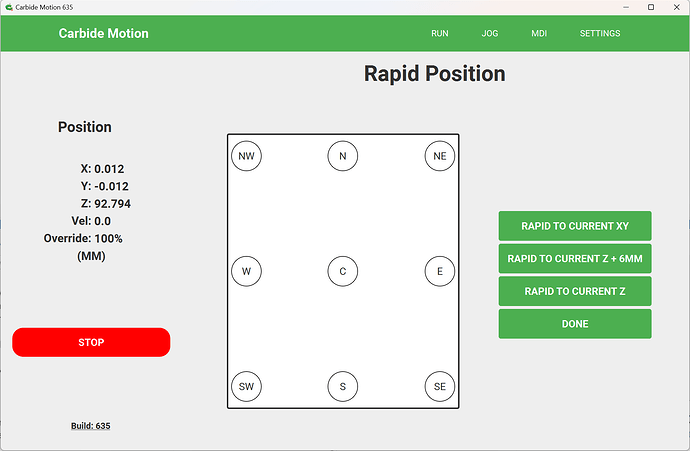

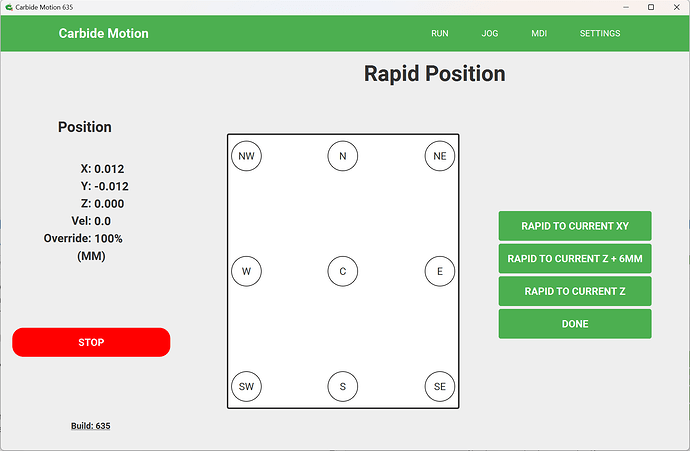

at which point it will measure the tool — it will then return to the Probe position, where if one removes the unit and uses the CM interface to Rapid Position to XY and Z zero:

One will find the machine has found the origin relative to the probed stock: