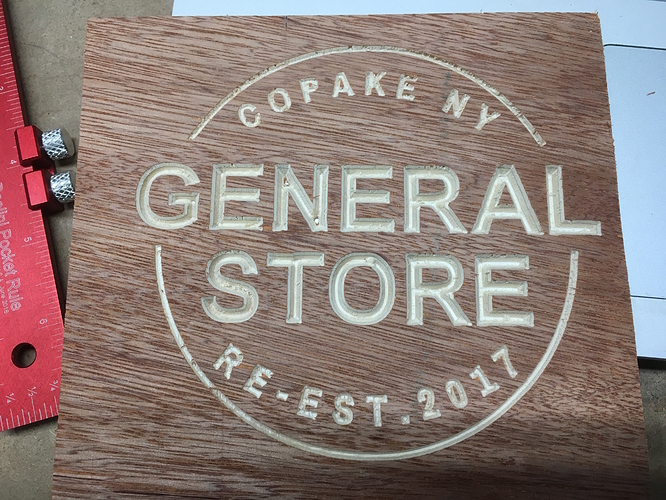

Here’s the full carve. Still a few anomalies (the top of the T and the top of the S, but it’s SO much better! Should I expect that level of accuracy, or can I do better somehow?

Also, the machine was going really fast in terms of IPM. I wonder if I slow it down if it will make a difference?

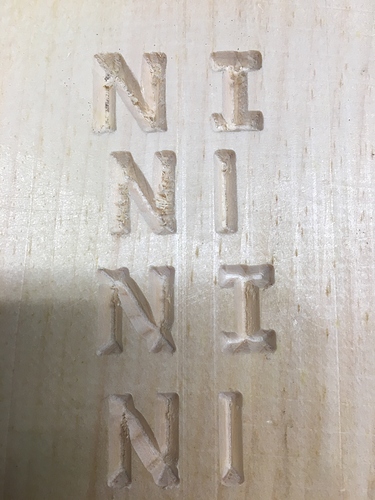

The top of the T and S look like mechanical issues:

- Pulley set screws: http://docs.carbide3d.com/shapeoko-faq/shapeoko-3-how-to-check-the-pulley-set-screws/ — be sure to check all axes/pulleys including Z.

- V wheels / eccentric nuts: http://docs.carbide3d.com/support/tensioning-eccentrics

- Belt tension — the Z-axis should be guitar string tight (but careful not to bend the motor shaft): http://docs.carbide3d.com/assembly/shapeoko/xxl/step-5-belting/ on deep cuts it may help to remove one spring from the Z-axis temporarily, esp. if one hasn’t added a spoilboard on top of the wasteboard — it also helps to install the router as low as possible (installing the Makita adapter upside down will help). Some folks have found it helps to remove bolts which won’t stay tensioned (M4 Z-axis tension bolt, various V wheels with eccentric nuts), apply a thin bead of threadlock along the length of the threads, then reinstalling. See the video at: https://www.youtube.com/watch?v=_lIIb_PdziA Note that the X-axis motor is held in place on standoffs and if those bolts are loose this can cause belt tension issues.

It is also important to be sure that the collet is correctly tightened, the endmill fits correctly and doesn’t slip, and the router is mounted securely in the mount, and that the mount doesn’t shift. Note than endmill pullout can happen gradually, especially when profiling against tall walls.[4]

Also feeds and speeds may be a consideration: https://docs.carbide3d.com/support/#tooling-support and see https://www.youtube.com/watch?v=S9bceJxpqG0 for concepts on this and https://www.precisebits.com/tutorials/calibrating_feeds_n_speeds.htm for a testing technique and see the series #MaterialMonday: #MaterialMonday on YouTube

Beyond that it’s usually a matter of Calibration and Squaring the Machine c.f., http://docs.carbide3d.com/shapeoko-faq/how-to-calibrate-the-machine-for-belt-stretch/

Maybe I missed it, is your bit really 6mm, or is it 1/4” (6.35mm)? If it’s really 6mm do you have a 6mm collet or 1/4” collet? Is it a 1/4” bit that you’re defining as 6mm? That tiny little 0.35mm makes a difference.

Dan

Hey @DanoInTx, he posted a drawing of the bit in a post above. It has a 3.175mm shank and a 6mm max cut diameter.

@philiphack I’ve used those bits from Inventables on a different machine. The angle was closer to 58° than 60°. Unfortunately, you may have to fine tune it with tests. Setting your zero accurately on flat stock is also very important.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.