Hi all,

I wanted to share some progress that I’ve made in integrating the vers.by WLR wireless touch probe into my Nomad workflow, including some documentation about what I’ve changed and various thoughts about the probe itself.

Anyhow, money up front, discussion after: it works, but needs support in the tools to be as useful as it can be. If you want details, read on.

I got wind of vers.by and their CNC probe business through this post by @DanStory in the Nomad forum. I’d become passable at using a traditional edge finder to zero my work on the Nomad, but as this is the first electronic touch probe I’ve seen that fits in the Nomad’s spindle, I had to give it a shot. The idea that I could use this for XYZ probing, in addition to neat tricks like centering on a hole or boss, gave me all the motivation I really needed to order one and tinker with it.

I have not used a real Renishaw probe, so I don’t know how one would compare to this device, but the cost difference is significant (~$250 shipped for this) and I suspect it would’ve taken me much longer to get moving with a Renishaw.

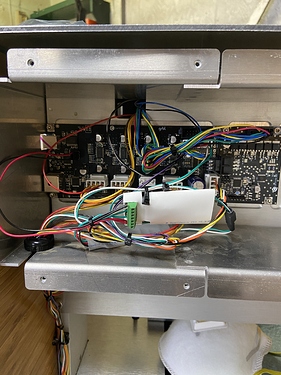

Integrating the probe into the Nomad’s electronics was fairly simple, though it required the creation of a junk-box wiring harness. The receiver for the probe draws power from the +5V present on the Nomad’s control board, and hooks directly into the machine’s probe input. The switch input from the tool length probe is passed through the receiver, allowing the use of either or both. The tool length probe can be used to measure the length of the Vers.by probe.

I had to bang together a quick adapter circuit to convert the NO switch output from the tool probe to the NC input the receiver expects, but this only required a single resistor and NPN transistor.

Wiring done, I protected everything as well as I thought it needed (heat shrink tubing and zip ties mostly), then buttoned it all up in the Nomad’s electronics compartment.

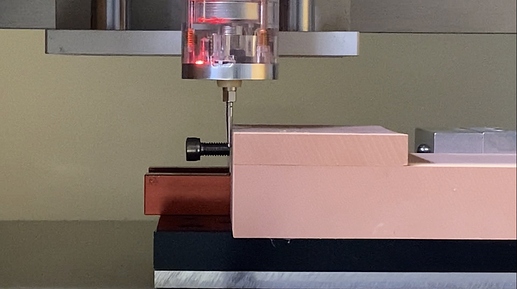

For gcode senders, I stick to CNCjs as it’s fairly turn-key and works under linux. I tested the setup with a G38.2 probe command, and it successfully found the side of an unsecured hunk of Renshape.

I don’t have a convenient way to share videos at the moment, but the one I have isn’t terribly impressive anyway. Using manual gcode commands, I can G38.2 probe in all three axes. Accuracy and repeatability are both seem acceptable, but I won’t know exactly how good they are until I’ve gathered more data.

This leads me to why I don’t have a more impressive video to share: as much as I like CNCjs, its probe support is extremely basic. It can only do single-axis probing, so more complex operations become multi-step processes, the details of which are left to the reader to work out.

What this really needs to sing is software support for multi-axis probing. I could see this added as either a widget in CNCjs (to replace the existing probe widget), or as an enhancement to Fusion’s grbl post processor to support probe operations. I’m halfway to a working grbl post, but it’s definitely in need of additional work before I’d consider sharing it. For now I’m content using the grbl console and issuing the G38.2 commands interactively.

Some additional notes follow.

Good stuff first:

- Vers has reasonably-complete docs published on their website, and everything I needed I eventually found in their user guide.

- Probe accuracy and repeatability seem good. Two probe cycles against the fixed jaw of my vise landed in the same spot +/- 0.01mm, but I haven’t trimmed the probe for concentricity yet out of laziness, and haven’t generated more data than that simple spot check (also out of laziness).

- Battery life is excellent. I’ve had the probe for about three weeks now and have used it a half dozen times in anger, and it’s still on the charge it arrived with.

- The receiver board’s got a little buzzer on it, so I get an audio indication of when the probe is tripped. Bonus, since the tool probe output is now routed through the receiver, I get an audio indication of when it’s tripped too.

- The receiver can be integrated without permanent changes to the machine. If I wanted to remove it for any reason, I’d just have to cut some heat-shrink and swap some connectors.

Less-good stuff:

- Delivery from Belarus took a while. COVID restrictions meant they weren’t able to ship for about 5 weeks, which was a bummer but outside anyone’s control.

- Some of the user guide looks to’ve been translated from Russian, meaning that there are quite a few rough edges. That said, it was all comprehensible enough to get its point across.

- Powering on the machine now requires me to at least turn the probe on and off to initialize the receiver board. This isn’t a huge deal, since on power-up the buzzer goes off to remind me to do exactly this, but it’s an additional step that I didn’t have to take before.

I’ll update this forum post when I’ve arrived at a setup that can do slightly better than the single-axis probing cycles it’s doing now.

Good question and something I have spent a while looking at. A Shapeoko ATC is a very cool idea but really needs to be well thought out. As standard GRBL doesn’t support any kind of ATC function, there are no dedicated outputs, no stored tool offsets, no function around tool carriages. It also requires a ATC spindle of some variety, a bunch of inputs/outputs for safety and likely air or another kind of pneumatic device to drive the tool changer. All in there is a significant gap in hardware and software which needs to be closed.

Good question and something I have spent a while looking at. A Shapeoko ATC is a very cool idea but really needs to be well thought out. As standard GRBL doesn’t support any kind of ATC function, there are no dedicated outputs, no stored tool offsets, no function around tool carriages. It also requires a ATC spindle of some variety, a bunch of inputs/outputs for safety and likely air or another kind of pneumatic device to drive the tool changer. All in there is a significant gap in hardware and software which needs to be closed.