Thank you

Thank you to the team at Carbide 3D for designing and building a great desktop 3-axis CNC! The Nomad 883 Pro is a great machine.

My 2-year endeavor is finally complete, and the final video is now available on YouTube. Enjoy!

I should note: this is my first -completely from scratch- watch.

Introduction

This video captures 1,440 hours of work in six minutes, detailing the process from CAD design to manufacturing from scratch, including the case, band, dial, hands, movement, every gear, every screw, even the spring bars for the band and buckle … a total of 122 parts made from scratch! Some parts are smaller than Lincolns nose on a penny! While the Nomad is a great and very capable machine, fewer than 20% of the parts were made on the Nomad CNC, the rest were done by hand using traditional watchmaking methods because the Nomad is not precise enough for watchmaking (watchmaking parts require 0.001mm precision!).

Very few people in the world make the entire watch from scratch, particularly the movement. This is because making gears (called wheels) from scratch, requires such precision that an error of 0.002 mm will result in a fancy paperweight, instead of a watch that maintains chronograph performance of -4/+6 seconds per day. It is difficult to appreciate how hard this is, especially when you know that nearly 1000 hours were spent working under a microscope with 20-30x magnification to make the wheels, pinions, screws, etc. The international roster of “Independent Watchmakers” lists fewer than 200 names. I hope to someday add my name to that list.

Tools

With the exception of Guilloche, all associated jigs and fixtures were designed using Fusion360 for CAD design and CAM tool-paths. The CNC work was performed on a Nomad 883 Pro 3-axis CNC mill, while all other operations were performed using a variety of manual machines and tools, e.g. a 1940’s Boley F1 lathe, and various tools from Levin, Bergeon, Leica, K&D, etc. To build and assemble this timepiece, over 3,000 tools were purchased and +50 jigs and fixtures were made from scratch.

Materials for the Case, Dial and Movement

The case and crown are made in a brilliant platinum (Rhodium), for long wear and scratch protection. The case is water resistant to 10 meters. The front features a double-domed sapphire crystal to resist scratches and accentuate the beauty of the dial, while the case back uses a flat sapphire crystal to display the beautiful movement.

The dial is also made in platinum with 18k gold hour indices and chapter rings. The hands are hand-made from high carbon steel, heat treated to a deep blue, and mirror polished tip and boss.

The movement is made in platinum, with high carbon steel pinions, 24k gold wheels, and ruby jewels. In the tradition of high horology, each hand-made screw features a chamferred and polished slot, and mirror polished screw head. All steel parts in the watch are mirror polished, the most visible component (aside from the screws) is the escape wheel.

Leather Strap

Havana leather, the king of patina, picks up marks and scratches which quickly blend gracefully into the subsurface.

Every strap is saddle stitched by hand as shown in the video. Unlike lock stitch created by machines, a saddle stitch is more durable as it is made of two independent stitches that form a knot at every stitch. Linen thread in 0.35mm thickness was selected for a fine and natural weave.

The edges are finished with multiple layers of edge paint to seal the raw edges. To achieve the desired finish, the edges are repeatedly sanded and edge paint is applied.

The strap is lined with silky smooth Nubuck leather, specially developed for use as a lining material. It is soft to the touch and comfortable even after hours of wear. The leather is water- and sweat-resistant and works well even in hot and humid climate.

The straps comes fitted with a brilliant platinum (Rhodium) hand made buckle, straight grained surfaces with mirror polished chamfers, engraved with my family name. It brings about a sophisticated yet durable look to the strap. Even spring bars are hand made on the Boley F1 lathe!

Select CNC photos

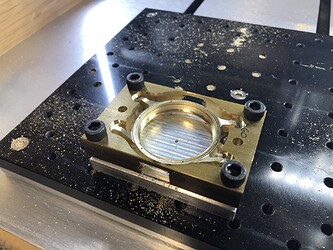

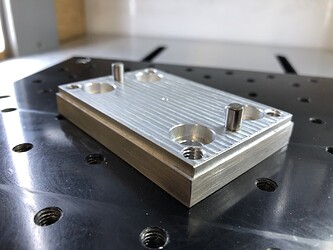

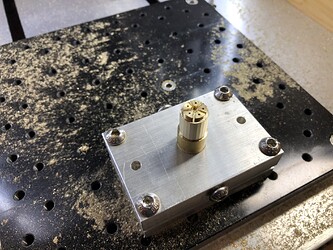

Bottom side of the watch case.

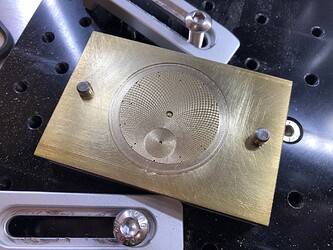

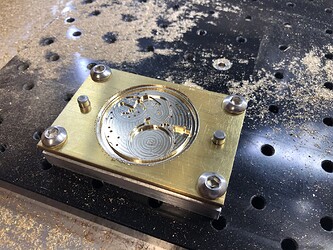

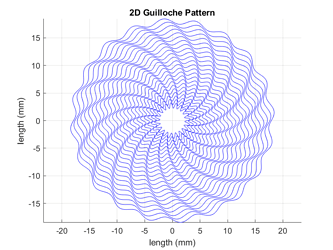

Guilloche dial (I had to write my own CAD and CAM software to do the math and geometry for this pattern)

Prototype hands and hour markers for the dial

Movement bridges

Movement main-plate

Wheel blanks (prior to cutting the teeth)

Guilloche Notes

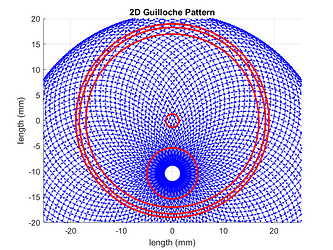

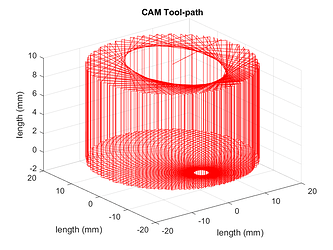

These are the Guilloche dial tool paths. To do Guilloche, I first created the math and geometry algorithms, then wrote the software for the CAD and CAM from scratch in Matlab. Therefore I can generate plots (like the ones shown) as well as a simulation and the g-code. The simulation can be viewed from any angle and zoom in real-time, just like you would in something like Fusion360.

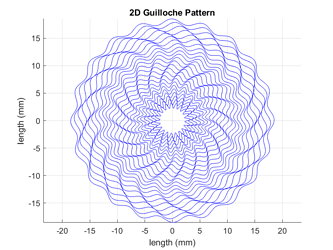

The code is quite flexible. Here are other pattern examples (that I didn’t use)

Selection of jigs, fixtures & tools made on the Nomad

Flip jig to precisely align material for 2-sided machining

Branding iron for the leather strap (for scale, the text is 2.5mm tall)

3-axis fixture for pearlage and Geneva stripes

Fixtures to hold the bridges while mirror polishing the chamfers

Mandrels to hold the wheel blanks while cutting the teeth