Nice, you got it

Yes it does, if the data cable passes the ground. In the good old days when I custom made cables, we only connected the shield ground to one side. Today ??

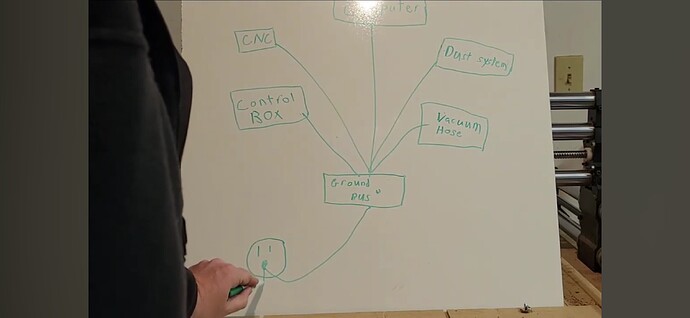

So because of this loop, We try to plug the Computer and CNC into the same circuit. it makes the ground loop small and reduces the chances of weird ground loops things happening.

Just FYI there are many different types of noise.

Ground loop is a bit different. This is when electricity get coupled into the loop by passing by some electrical source through the air, think of it like the magnet trick. If I put a magnet on top of a piece of cardboard and another under it and then wiggle the underside one around, the one on top moves too. Magic. However if the magnet is too far away then nothing happens. In this case electricity is basically the same.

When this happens phantom currents start to flow on your ground. The issue with a loop is it can it starts to feedback on itself and around and round the loop it goes getting bigger. Sometimes there no issue as it does not pick up a coupled source. sometime weird stuff happens. So you can see why we try to avoid them and if not we try to keep them small. We don’t want this type of current flowing around and round the loop

Other noise, Every time we make or break a contact there is an Arc and that sends out all kinds of noise. Welders create an arc that keeps firing. Dimmer switches can pulse AC to reduce the brightness, Noise. Badly designed switching power supplies like low voltage lighting, Noise. Any brushed motor. IE your Vacuum, Noise  look at the sparks in a corded drill.

look at the sparks in a corded drill.

When these sparks happen it shoots out noise and harmonics of that noise which basic gives us high frequency noise. Like static on your am radio. This noise interferes with computer components which are also running at high frequency. It can make the CPU in the controller completely get lost in what it was doing. and sometimes it just miss a beat or memory randomly got changed. A glitch as we call it:)

I would not expect my laptop to function well when I am welding

Vacuum hoses and lines grounding is not really noise. It is a static build up. a high voltage charge. If it gets high enough and releases, it can create a noise spike or worst, a spark that ignites sawdust. So we need a ground to bleed off the static charge as it tries to build up,

OK hopefully that was just simple explanation.  I don’t want to get too geeky. We seem to talk about ground loops, ground vacuum hoses and noise here and on other threads, they are different but require ground for different reasons, so I thought I would just take a minute for whoever else is reading this as it does get confusing on what you are trying to solve:)

I don’t want to get too geeky. We seem to talk about ground loops, ground vacuum hoses and noise here and on other threads, they are different but require ground for different reasons, so I thought I would just take a minute for whoever else is reading this as it does get confusing on what you are trying to solve:)

Grounds provide paths for noise and static to travel, hopefully away from sensitive areas, however if we just start slapping grounds all over the place then >> ground loops and we get other problems.

You asked about a poor mans choke as I call it

A choke / inductor is simply a coil of wire, this coil basically creates a magnetic field. This field absorbs fluctuations in current. It lets DC pass as it is just a wire to DC. But to higher frequency AC, it does not like current that changes, so it absorbs them in to the field. OK a bit geeky  Basically an inductor can “choke” AC high frequency noise while allowing DC to flow.

Basically an inductor can “choke” AC high frequency noise while allowing DC to flow.

Coils can be air coils, or wrapped around something or they can have a ferrite core or similar which enhances the field effect.

Poor Mans Choke on the DC line;

OK first off I assume;

- the DC line to the controller is a shielded cable. it should be.

- the shield is the frame ground and there is VCC(positive) and logic ground (negative) wires inside the shield.

there should be

there should be

Just wrap the DC cable around 3 of your fingers 3 or more times. the more the better  use zip ties or tape to hold the shape of a 2" ish round doughnut for this cable. Ta-Da you made an air choke. It will choke high frequency noise on the shield with no effect to the DC power inside the shield

use zip ties or tape to hold the shape of a 2" ish round doughnut for this cable. Ta-Da you made an air choke. It will choke high frequency noise on the shield with no effect to the DC power inside the shield

Note people will curl their cord up to make it look nice and they inadvertently choked the frame ground, restricting the path. make sure you have added an alternate better ground to the frame in this case.

I just grabbed some images off the net as it is 3am

This person used a ferrite bead to enhance the effect

I used a split core on mine and ran 4 turns through it

Disclaimer

I am sure there is lots of advise out there and everyone’s noise issues can be different. I am giving my humble opinion based on my experience and what worked for me on my machine and my rational as to why .

Hope you are all having a great day, happy carving