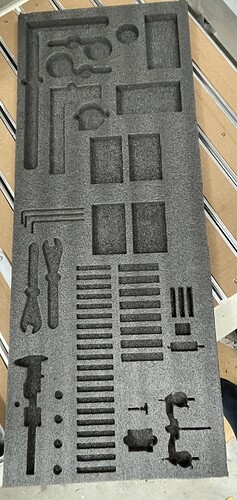

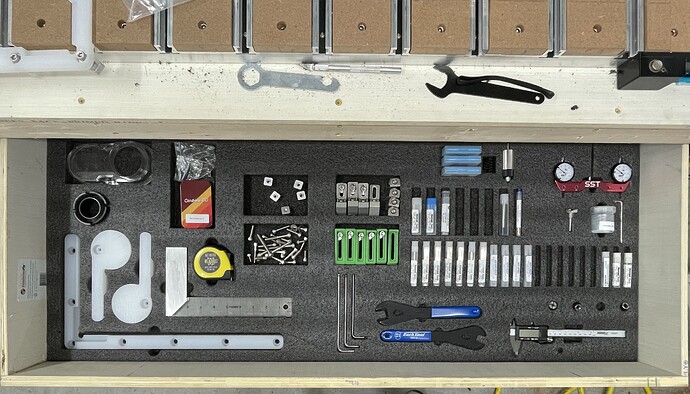

I finally cut the foam insert I bought for the drawer I added under the machine. The foam is 18x45+ so too long to cut in one section. I didn’t want to pull the machine away from the wall so I did a poor man’s tiling job.

I designed the whole layout in a single file and then picked a spot to split it. Created 2 smaller sections and rotated one 90 degrees and the other -90. Then loaded the material and let it hang out.

It turned out nice but I had to pause the jobs a million times to clear the bit. I removed the sweepy and held the dust collection near the router but I still ended up with foam wrapped around the bit a lot. It was worth the effort though. I was tired of digging for bits in a ziploc bag.

Tomorrow’s project is remaking the HDPE angles to be a bit wider so that the piece parallel to the Y axis doesn’t fit between the MDF slats.