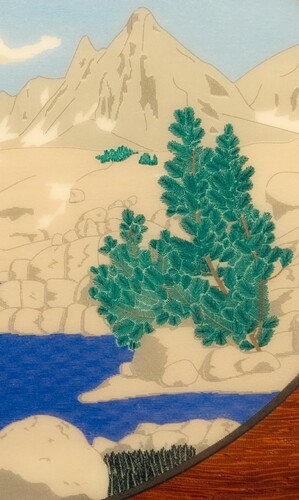

My second venture with layering engravings on faux ivory with colored India inks. The process is getting cleaner and more defined, this one took nine passes. The oval is about 120 mm (4.5 inches) wide.

Here’s a crop to show the engraving lines.

[I have posted far more detail about the process in the Gallery for the first of these: Dragonfly Tidytip Engraving]