You could make some really long-lasting Oreos like that, but the kids wouldn’t like you very much

I have not had cable or satellite tv for about 6 years and I miss Cartoon Network. That Steven Universe was funny even to me as an adult. Some of those Cartoon Network shows were entertaining and other animated series seemed to have a level that kids enjoyed but adults saw different things on another level.

Cute Cookie Cat. Maybe some kids could use them as tokens on a board game like Monopoly or other game.

If he used balsa wood and coca powder they would possibly taste the same and have more fiber.

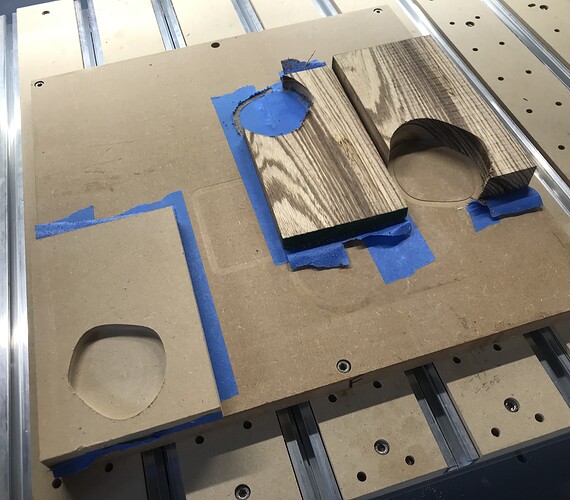

Salt cellars are fun and easy and if you use a figured wood, can be quite pretty.

Zebra wood in this case. A chunk of 8/4 bandsawed to achieve the one piece look.

Setups:

Fill the S with salt and thin CA, your done!

Designed in F360. Finished with Tung oil, one coat so far on this piece, will need 2-3 more.

Thanks!

I’d say it works similar to sapele and African mahogany. Once properly finished its quite nice. I’ll post back when this one is done.

I’ve seen pieces made from olive wood, never worked with it.

Nice use of the contained material as label, there’s an elegant simplicity to that.

I would agree with you on Olive wood Jeff. I haven’t used any on my cnc but I used to turn it on my wood lathe, it’s like turning soap, the stream of chips just fly over your shoulder, very easy to get carried away! I can’t seem to find anyone over here (in the UK) that sells it.

I don’t know whether Zebra wood is the same as Zebrano wood but they look very similar, Yandles here in Somerset stock it and also have an on line shop.

glue gap in a cutting board is a disaster waiting to happen.

such crisp inside corners!! outstanding work!! i’d be interested why you chose this over v-carve?

I used a 10 degree V bit, and a 1/8" clearance bit in Vectric v-carve.

Graham - Would you mind sharing the exact V-bit that you’re using? I’ve got the bug for cutting boards now and I’m working with some really hard wood.

Great work, thanks for the inspiration!

Edit: Watching a couple of videos from Stephan Forseilles, I see that he uses a 15 degree V-bit. Do you have a reason for using the 10 degree that works better for you?

Thanks Mike.

I don’t have the full details of the V-bit to hand but I bought it from the Rennie tool company here in the UK. There was no particular reason for choosing it, I had used the 15 degree bit for my version of Stephan’s You Tube button, which worked fine. I just wanted to to try a different bit to see how it came out. It probably also helped to clear out the furrows on Walt’s brow etc.

Keep up the practicing, it pays dividends in the end but can also be very infuriating at times.

Made these almost two months ago, but finally have some time in front of a computer to post about them.

Modeled in Fusion360, brought to life by a Shapeoko 3 XXL. Roughing and parallel pass done with a 1/4" upcut bit. Total Machine time per paddle 4 hours.

Curly Maple, Black Walnut & American Cherry. Laminated with Titiebond 3, finished with tung oil for the shaft/handle and spar urathane mixed with tung oil for the blade.

First ever paddles. First project that has exceeded my expectations, so proud!!!

Excellent Tyson. You have every reason to be proud.

I can’t wait to see the canoe!

Now there’s a tiling project if ever there was one.

My first time machining aluminum.

Aluminum Guitar Neck

<iframe width="560" height="315" src="https://www.youtube.com/embed/D1ah-rR3SHk" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

@markgutierrez, I found myself watching the full 20minutes of that video, this is awesome, and a tribute both to your talent and the capabilities of the Shapeoko!

Thank you for sharing such an in-depth look at a full guitar build process, and welcome to the community.

Probably my favorite use of our Shapeoko’s, useful problem solvers.

First shot at inlay with some crappy pine to iron out the kinks first.

Fusion 360. Will report back once I’ve dialed it in.

Come on, it’s almost customary to mess up one’s first inlay by forgetting the flip the male part in the design, and you dodged that bullet ?

Any specific reason you are going for straight inlays rather than v-carved ones ? (which are tolerant by design to small dimensional errors, whereas for straight inlays you’ll need a perfect fit)

Does Fusion have a ‘smart’ toolpath like VCarve which can get square-ish corners for an inlay then? I did a bit of searching but didn’t find anything yet.