#102 1/8 0.125 flat cutter endmill

Always useful to make some storage for the workshop and a new lamp for my son’s lego table in his room. Not too complex, and pales into mediocrity compared to some of the items made on here!

I love that lamp. I might need to make one for my kids.

I had to double take the picture of the motorcycle rider. For some reason I looked at first like a goose with a vest on. Then I realized it was a motorcycle rider but the part of the motor cycle facing me looked like the back of one. It is weird what you think you see sometimes.

Nice work as usual.

Technically mono cycle ![]() but I’ll take goose as well.

but I’ll take goose as well.

Shiny and over engineered, not a bad usual to be! Thanks

I forgot to add that the material is the Dollar Tree bamboo cutting boards. The bit holders I found on AliExpress - they turned out to be holders for bit used in nails (like on the end of your fingers, not nails like you’d use to put wood together :-)) The diameter of those drills is a little smaller than the 1/8 shank bits I normally use, so I milled a small fixture to hold five of the tops at a time and used the Nomad to widen the holes to 1/8". They aren’t solid, just 4 vanes with a gap between them. The milling slightly melted the plastic but was pushed away by the milling still stuck to the vanes. That turned out for the best as it gives a little more purchase to the shank of the bit and if it had completely cut off. The first picture shows the closed holder nestled in front of the Nomad. I had found some cards that are 18" x 24", which is a great size for the Nomad. I can roll the card out from it’s normal hiding spot to do my work and, when finished, roll it back. The room I’m using is very small (81 square feet, with two walls completely taken up by the Ikea Kallx cube units for storage), so I have to make sure everything fits and can be put away.

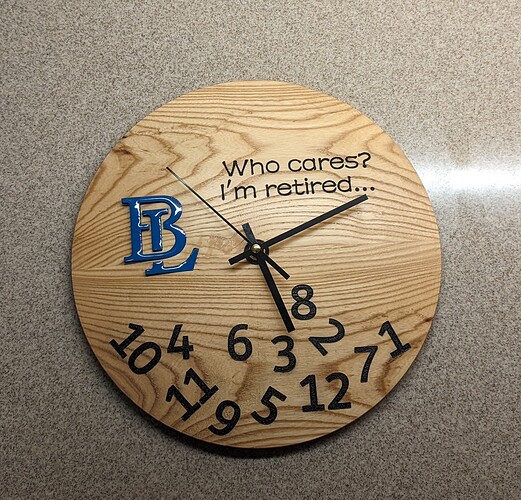

I was commisioned by a coworker to make a retirement clock for our kinder teacher. Wood: ash. This was a double sided project on Vectric on a Shapeoko 5. Used my Jtech laser to do the letters. I also used a black powder coat on the letters and burned in with a second pass with the laser at a smaller power setting. Laser cut BL, painted, glued in, then epoxied.

A few years ago I went to a turning club meeting in Texarkana TX and one of the members had a tee shirt that said “This is as dressed up as I get, I am retired”. My retirement wardrobe is all tee shirts and blue jeans. I only have one set of dress clothes for weddings and funerals. I used to wear suits 5 days a week and I have one suit hanging in the closet and have not worn it for a long time.

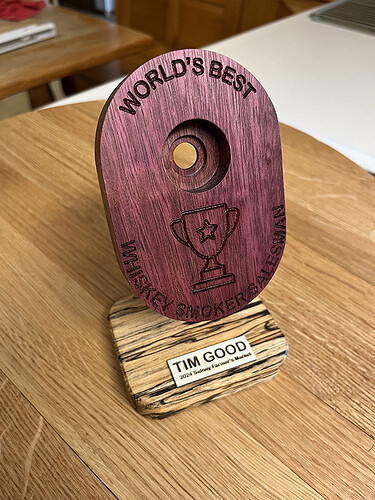

Decided to sell some wares at the local farmer’s market this year. One of the items is a whiskey smoker. My brother-in-law was there last week and he brought the smoker I made for him awhile ago and set up a little demo station. Between the campfire smell of burning oak chips and the showmanship, it drew a bunch of attention to our booth. We sold over a dozen whiskey smokers!

So, I decided to make him a little smoker-shaped trophy out of purpleheart since he was injured in the line of duty (burned his fingers a few times haha!)

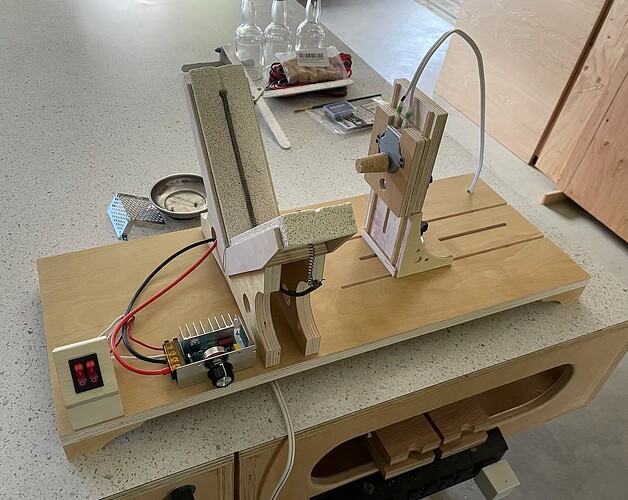

Used my 5 Pro to make this bottle cutter. Easily made some nice sliding components to position the bottle, switch housing and supporte to hold the kiln bricks & heating element.

Quick Father’s Day gift project last night for my father-in-law. I purchased one of these knife kits from my local Rockler along with some 1/8” leopardwood stock.

Followed the techniques in the video from Winston and scanned the profile of the knife on the scanner and traced it in Fusion.

The grain of this wood is really neat! I totally could have done this project with hand tools, but I have been trying to learn CAM in Fusion so this was some good practice. ![]()

Very nice knife scales. I bought a knife from Woodcraft and it had a very faint piece of paper that was not to scale. I tried to scan it with no a lot of success. The knife is still in my stock of things to do. I was very disappointed in the knife. My grandson likes the knives with the pin like on yours. I hate those type of knives and have a Spyderco for about 30 years that has a large hole to open the knife with.

For me and my hand that type of opening device works well. I just find it hard to open the ones with a pin.

Lately I have been investigating a new knife sharpening system. I have a Spyderco ceramic triangle stone system that holds the stones at two different angles. It works but want something easier to setup and use. I have been thinking about the Ken Onion Edition

Does anyone have one these to comment on?

I got a similar Worksharp (and a bunch of ceramic belts — long story) and I found that I didn’t like the speed of powered material removal and much prefer the slower and more deliberate manual process and the lessened likelihood of rounding off a tip or otherwise over-doing things.

Since my eyes and hands aren’t as steady as they once were, these days I use a guided sharpener like to a Lansky (and have making a really, really nice and over-engineered one as a some-day project).

There are a lot of different types of sharpeners today. I have seen the round ceramic ones that seem more oriented to sharpening kitchen knives. The Lansky is a good sharpening system but has a lot of set up for different knives. If you sharpen the same knife over and over seems like a good one. I have a Worksharp tool for sharpening plane irons and chisels and I wold agree with your that you have to be careful because of the speed and regressive nature of sand paper. However those tools are flat and square usually and knives have curves and points that can as you said get rounded off.

I will keep researching to find myself a good sharpening system. A good sharp knife is a good tool for CNC work. Around here everyone has a knife including old women and little girls. My knife is my sharp extended finger to use for a wide variety of functions besides cutting boxes open.

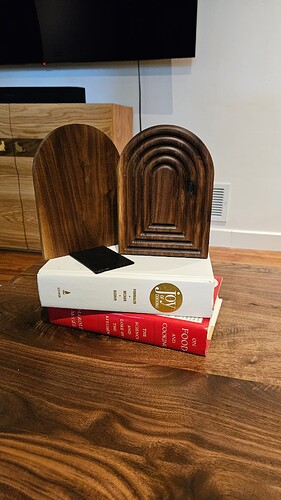

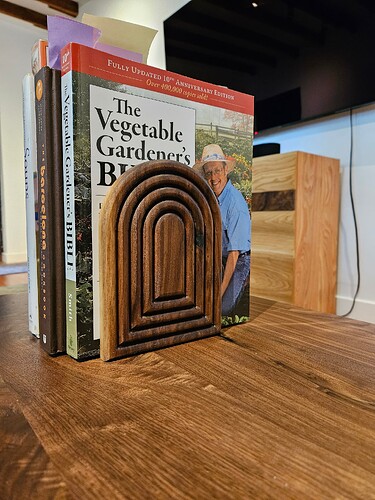

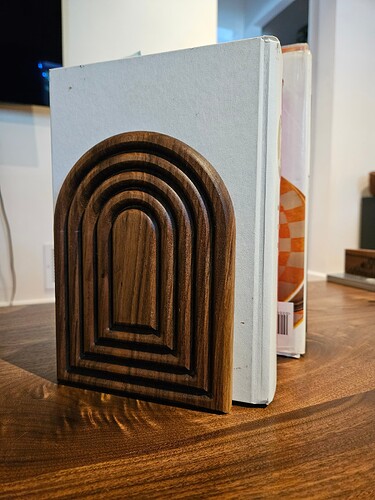

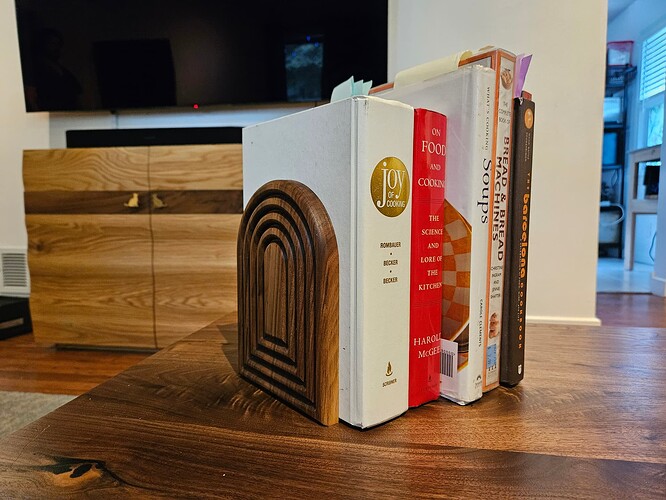

Quick Sunday project: much needed book ends.

The stock wasn’t completely uniform thickness, but the patterns still came out well, I think. FINALLY, got to use my roundover bit.

3D printed the plastic strip to keep it stable and upright.

Used a piece of Walnut that was from a failed project. I love it when these waste pieces are used.

Finished with a homemade hardwax oil finish.

Very nice book holder. Maybe in our modern age you should have made a phone holder to hold up a phone or tablet. Books are becoming obsolete. I get a lot of woodworking magazines and still prefer to read the physical magazine as opposed to the digital editions but in our digital age books are becoming more and more rate. So hang on to your Joy of Cooking, it may someday be sold at a rare book seller for millions of dollars. ![]()