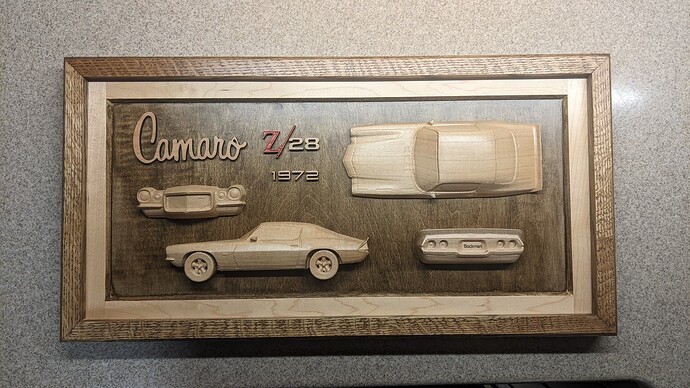

I made this for a former student of mine whose husband is a Camaro enthusiast. Car profiles are made of maple as well as the base. Outermost frame is oak. Text was cut with a laser. Red Z was powder coat. This was a fun project to make with new challenges. Car profiles took 3 hours, however it took me 3 different times to get it right. First time I used a wood that didn’t turn out the way I wanted it. 2nd time the wood block pulled up just a bit enough to mess up my project. 3rd time was the charm with improving my setup.

Text-on-text name plaque. 7"x14" Sapele. Sunflower applique on last name layer. Semigloss polyurethane over Tung oil.

Beautiful work! One suggestion is on displays like this is to have a glass or acrylic cover to keep the details dust free. A deep pour epoxy would be killer as well. Still a very nice piece.

Nothing.

Friday is my usual day to devote to the shop. I am off work and the kids are in school. Helene had different ideas this week. School was canceled and we have been without power since 1:30 am Friday.

I have 15 trees down and at least another dozen that should come down. Not a single one of which is worth milling for the workshop.

This is kind of a morbid competition, but when Ike came through my neck of the woods, we had 40 trees down around here; small to large. Looked like a box of matches spilled out. Not one of them touched a building, though.

And none of them were worth more than pulp.

Now we’ve got another storm forming in the same place Helene came from.

Hope you get some help cleaning up. I have a sister that lives in Nashville, Georgia (south of Atlanta). I haven’t heard from her, yet.

Interesting. I have lived in Ga all but 10 years of my life and driven to Atlanta countless times and never heard of Nashville Ga.

Hopefully she is fine. There are very wide spread power outages in the state. The latest I heard was that they were hoping to have estimates for time of restoration by late today. I drove around some yesterday and saw lots of trees on lines. What I didn’t see was a single tree crew or power crew so they are otherwise engaged.

There are small pockets here with power, but not much.

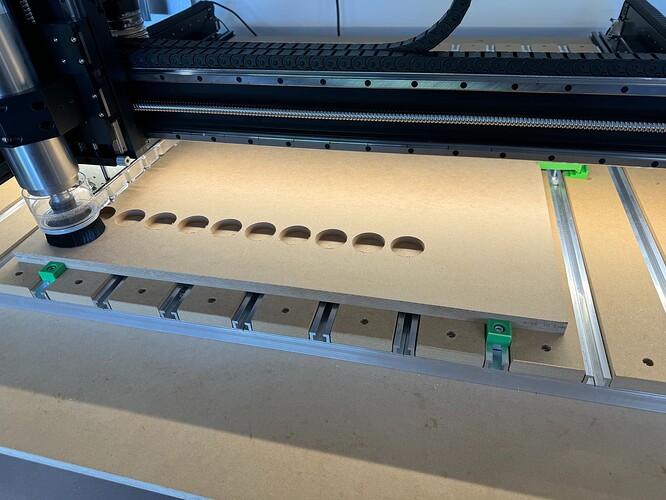

I made the first project that was more than a 5 minute cut. It ran for around 2.5 hours. It goes in a drawer in my wife’s sewing room and is used to “organize” her spools of thread.

I have a fabraholic wife that has a warehouse of threads, Hmmmm…

Great idea! Looks really tidy

(If i may, you could add a header, or use the drawer face to drill holes to feed the thread through. Label each hole coresponding to thread position)

If your wife ever complains about your tool budget add up all that thread price and present that to her. Likely she wont complain about your tool purchases any more.

It is amazing when you start adding up all the odds and ends that it takes to do a hobby. I need to do an inventory of my tools but I am almost afraid to do that because I will realize how much money is invested in my woodworking. So that tool inventory has been accumulated of 50+ years and sometimes I am astonished on how much tools are in price compared to what I bought many of these tool at 50 years ago. I still have tools from when I was a teenager. I may be over the hill but I can still clearly se the top of the hill in the rear view mirror. ![]()

I started buying tools in 2018 and have since accumulated a deposit on a house’ worth plus inherited many as well I wouldn’t even know the value on.

A good example of what you’re experiencing is milling machines bought in 2013 are worth about 4x right now, a chinese label like a PDM-30 was about 800-1000$ on sale and is now like 34-3500 CAD you could use that machine the entire time and still flip it for more than double what you paid. Heck I seen one rusted up from the 90s for 3000 recently. It’s insane but it also makes me happy I invested in tools and not anything else. Especially Tech!

Hm that makes me want to tackle my spice drawer… looks very nice.

Super easy to do, it was one of my first projects. I do regret not labeling them though since I can no longer see the spice inside as its too deep also consider two pieces of ply with a 1 inch dowel between them as even 3/4" ply isn’t enough to keep them from being knocked over.

I made my first 3D project with CC Pro. It’s a tray of sorts with a local school’s logo. The school asked for donations for an auction, so i figured it would be a good way to do some market research.

I used 8/4 cherry and finished it with wood honey.

I live next door to Louisiana by about a mile in Texas. I go to Louisiana on a regular basis and people in Louisiana are very proud of their state outline and the Fleur De Lis.

Indeed we are. I have an office in Shreveport. Maybe we can grab lunch sometime and talk about woodworking.

Thats awesome!

Where did you get the file for the 3D printed side support. I love that idea!

I sell then on Etsy.

I just ordered the 3d print files. Thank you.