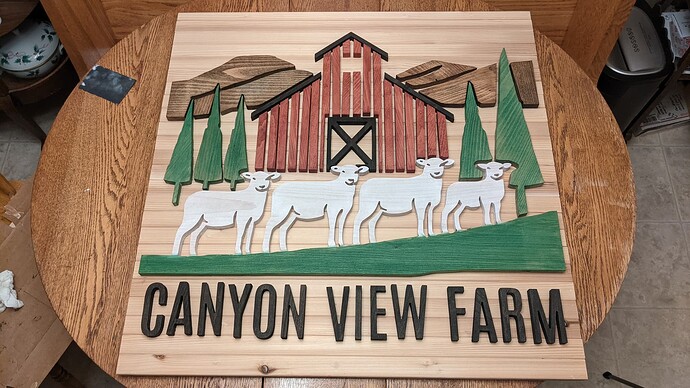

I’m working on a project for a friend. He will have this hanging on his barn facing the west which gets the wind and rain. I live in eastern WA where it is more arid. Thoughts on how to finish this project up. The pieces aren’t glued yet. I’ve thought about boiled linseed oil and and exterior poly. Wood pieces are 1/2 in thick beech. I’m going to use a water proof glue and also use a pin nailer. Thoughts for those that have made exterior signs to take the elements of the weather.

@Jonathan_Blank that looks really good, any chance you could share your process as far as cutting the different style pieces and design layout?

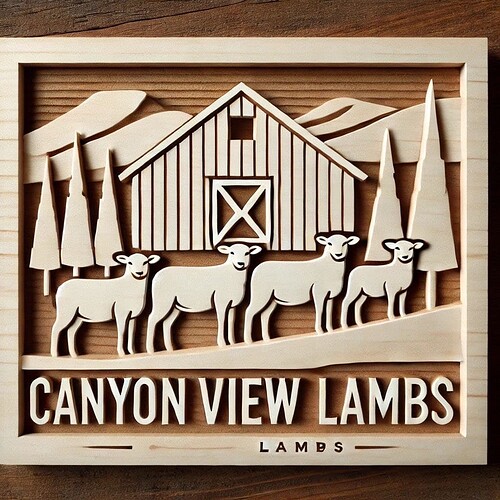

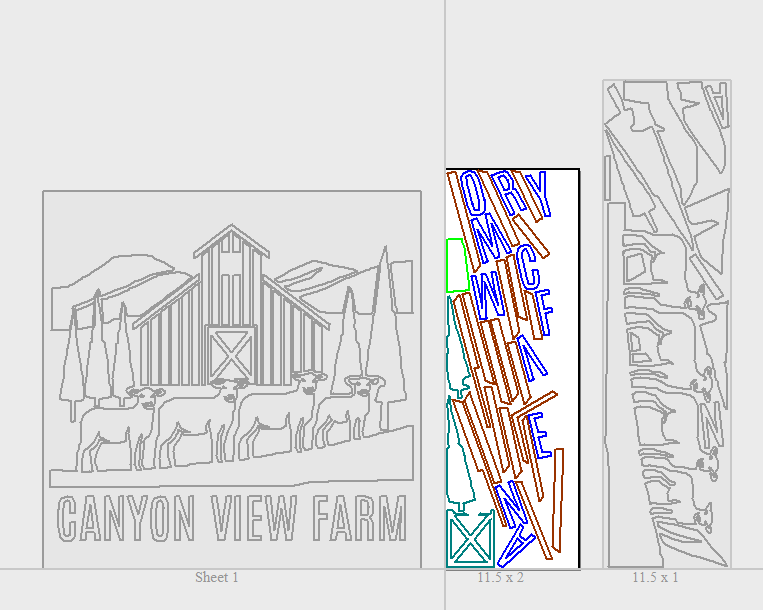

My friend gave me an AI-generated concept that he wanted to turn into a sign for his barn. I took the image and, piece by piece, created vector shapes to have a sharp file to work with. I used 1/2 inch thick beech for the pieces. Using Vectric, I nested the pieces to optimize my wood. Note to self: Set a larger gap between pieces so the wood is stable as the pieces are cut. The base is 1/2 in ply with cedar slates. Sanded all the project pieces and removed tabs. Stained. Now I need to finish things up with a finish and a frame.

Awesome thank you! Great idea

Looks great! I would put a good 5 coats of exterior poly on it to help prevent the weathering.

I would say pretty good artistry. All my drawings are really bad. All my circles look like eggs and all my eggs look like circles. I have had some drawing courses but I just dont have the artistic eye.

Your little animals are cute.

Jonathan

Sending that over to the wet side from the dry side of WA (“where we always have perfect weather”), i agree with Derek. I would make sure it it sealed with at least 5 coats of a material like Spar varnish. Nothing is perfect but that will keep it from needing to be resealed every year due to the constant humidity on the west side.

They are suberb. I would be interested to know how you did the fine black lines and light grey stripes on the cat. Is this epoxy?

Thanks

Ben, these are excellent. How did you do the glass? It looks like the brass is inlaid into it!

Thanks

The fine black lines were engraved with a 45° carbide drag bit then filled with India ink.

The substrate for all three inlays is “Resin-Ivory Slabs” from guitarpartsandmore.com. The “grain” varies quite a bit across these pieces, for the cat I chose an accentuated area. The fact that the grain is oriented perfectly was total luck.

Thanks for appreciating.

I finally got to doing the inlay in Maple and walnut. I’m really happy with the way it turned out. I did take gdon’s advice and used a 30 degree vee bit… advice well taken judging by the outcome ![]() There were still a few small gaps but I filled them with mixed walnut sawdust and glue, sanded it smooth and you would never know they were there.

There were still a few small gaps but I filled them with mixed walnut sawdust and glue, sanded it smooth and you would never know they were there.

Tried a complex inlay for first time. Came out ok except the bit became loose and fell into the work piece.

Thanks for sharing, it really is a great piece of work.

Came out really nice! Do you mind posting your tool path settings for the pocket and plug? Thanks!

Sure…

Feather 30 Degree Oval.c2d (164 KB)

Feather Inlay Plug.c2d (128 KB)

Beautiful. Great work.

I also submitted the project to CutRocket ![]()

Very nice work Jonathan.

Hey Jeff that looks great to me. I hav not yet played with the inlay stuff yet but very inspiring.

I get lucky where I live and find a lot of lumber for free, especially some of the more expensive woods. The only thing is, I have to go cut it into logs and then make my own lumber. I like finding farmers that are working land to open for cattle grazing and they come in and push all of the trees together and leave them for a later time to burn.

Usually, that is when i have been watching over time to see what is going on. Then one day I finally run into the land owner and ask them about the trees. I have come across some of the nicest looing trees, that yield some of the prettiest lumber. I have a portable chainsaw saw mill that i cut the logs with. Then I can plane the lumber smooth and flat. Seems like a lot of work on some of this, but when prices are as high as $500 or more for a single slab of walnut or maple, even white oak or red oak, I can’t see spending that much if I don’t have a client yet for a job. Also, with me cutting my own lumber sometimes, it allows me to take a few more risks with the wood, and if something fails in the cuts, I don’t feel so bad about having to toss something.

Right now I have a few different types of logs sitting outside my shop waiting to be cut into lumber, wood like, hickory, sassafras, mulberry, walnut, and red cedar.

I do like your design for your projects of the textured carvings that are enlays. Keep up the good work.