You nailed it, John. Winning “Best Supporting Tool” on a project is sometimes the Shapeoko’s role.

Nice! Don’t think the “45 RPM” adapters go un-noticed by some of us that actually used them! ![]()

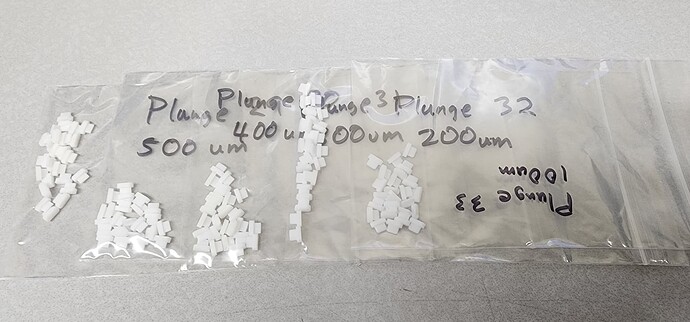

I watched the Carbide 3D YouTube video that @wmoy did about how small a S5Pro can machine. At work we got a job for 125 of these varying Teflon pieces, so I decided to continue the small trend on our HDM. We had made a batch before on one of our mills, but they took a lot of time and needed a lot of deburr work with fuzzies. They fit into the clear injection molded piece pictured and help some medical researchers with a project. The smallest features are 0.15 mm and the overall larger part is ~5 mm. I ran some test pieces to nail a very critical dimension with a negative stock offset. After that I programed the 5 different variations and got to cutting. They were dimensionally accurate to 0.001" and all 125 were repeatedly within that as well. I made extra in each variety in case the double sticky tape let go, or there was a variance. But every part stayed still and was within a very narrow variance and usable, so they get extra. ![]() I switched to a new 0.125", single flute downcut and the parts didn’t require any deburr. They were consistent enough that I found the expensive medical part they fit into had an inconsistency.

I switched to a new 0.125", single flute downcut and the parts didn’t require any deburr. They were consistent enough that I found the expensive medical part they fit into had an inconsistency. ![]()

Burts Bees for scale

The squares on the mat are 5mm. Razor blade for scale.

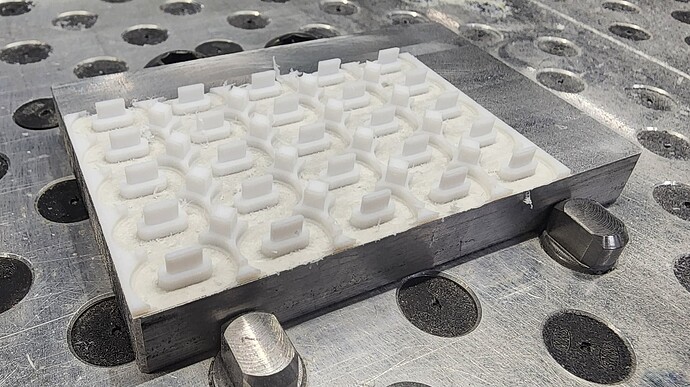

I did an array of 25. The aluminum block was machine leveled and parts held down with Nitto double stick tape. Legging a 0.010" onion skin on the bottom until the very last operation kept them in place.

125 super accurate Teflon parts bagged and ready to go.

That sure brings back memories as a consultant / contractor! I couldn’t figure out how some folks kept their jobs. ![]()

A friend saw a Farkle dice tray & wanted one for 10,000

My son stole my favorite cribbage board, so I made him a new one & got mine back

Wow !! Beautiful work.

I made some plaques for my woodworking club door prizes for last Saturday. Had Army, Navy, Air Force and Marines. I would have though we had some Marines but either none showed up or we dont have any. I did not make a Coast Guard and had one CG veteran so I need to make him a plaque. Your cribbage board is very nice.

How long did your cribbage board take to carve?

About 30 minutes with setup & tool changes. < 20 min tool paths.

Semper Paratus! to your coasty friend. ![]()

Nice work!! How did you finish your dice board?

The black & white are epoxy, so just one coat of polyurethane to bring out the luster.

On the Farkle tray, a couple of questions.

What is the “container” made of ? Looks like ply’s of something on edge.

I have never done epoxy.

What order of operations did you do the epoxy ?

This made my brain spin.

Yes, plywood strips glued on edge. It’s what I had ![]()

I cut the pocket, then poured black epoxy. Then I V-carved the lettering and rather than wait another day for epoxy, I used white bondo to fill. Then surfaced off the excess and cut the outside profile. A little hand sanding and a couple good coats of poly for durability.

Thanks for the info !

It’s interesting to hear someone else that can’t wait for something to dry.

White bondo, I would never have gone there.

Fantasy football trophy. Walnut and maple. Drawer lined with repurposed cigar box. Removable top locks in name plates. Plates sit in a sliding dovetail.

My first aluminum part. I took all the fancy features out of it, and had to adjust the mounting hole spacing for my Z+. Im pretty stoked about this machine.

Mounting plate for a air misting unit?

Correct. I have gathered all the parts now, I’m just waiting for some free time between jobs to set it up.

I have a small compressor just like that. I use for airbrushing my CNC projects.

I am hoping it will be sufficient for the mister ![]()

It wont, you need something rated for continuous duty. That compressor will have a 95/5 duty cycle (5% of the time it wont be charging) You’ll have success at first but after a while I was having major problems even with a CAT 1060S, id say minimum 2gallon tank with a 70/30 cycle rating, unless mine is just abhorrently high airflow lol. Running that longer than an hour or two at a time might prove to be difficult or smokey.