Here’s the current progression of my new watch brand, It’s been a long time since I’ve dedicated my focus, time, and effort on each operation of the product development. Indeed this was not easy but I delegated some of the tasks to my collaborators so I can focus on what’s important. Since I’m currently working on making the toolpaths function for my nomad 3, I decided to share some work here since I had the chance to looking at others, indeed I enjoyed seeing the crafts!

Gosh that’s gorgeous. Looking forward to seeing the finished product!

Hey there! Thanks for your feedback, I’ll do my best for you!

That was a DeWalt DWL611 router running at max RPM but unloaded as you noted. That machine was my first SO3, 16x16 cutting area. I have a SO3 XXL now, so I am not exactly sure how much more current it uses, but they use the same board, so they both have the same current max.

I am not actually using an UPS right now, because I upgraded to a 220V spindle and VFD, and I don’t have a 220V UPS… Yet.

But if you watch the video, the load never went above 20% of the capacity of the UPS.

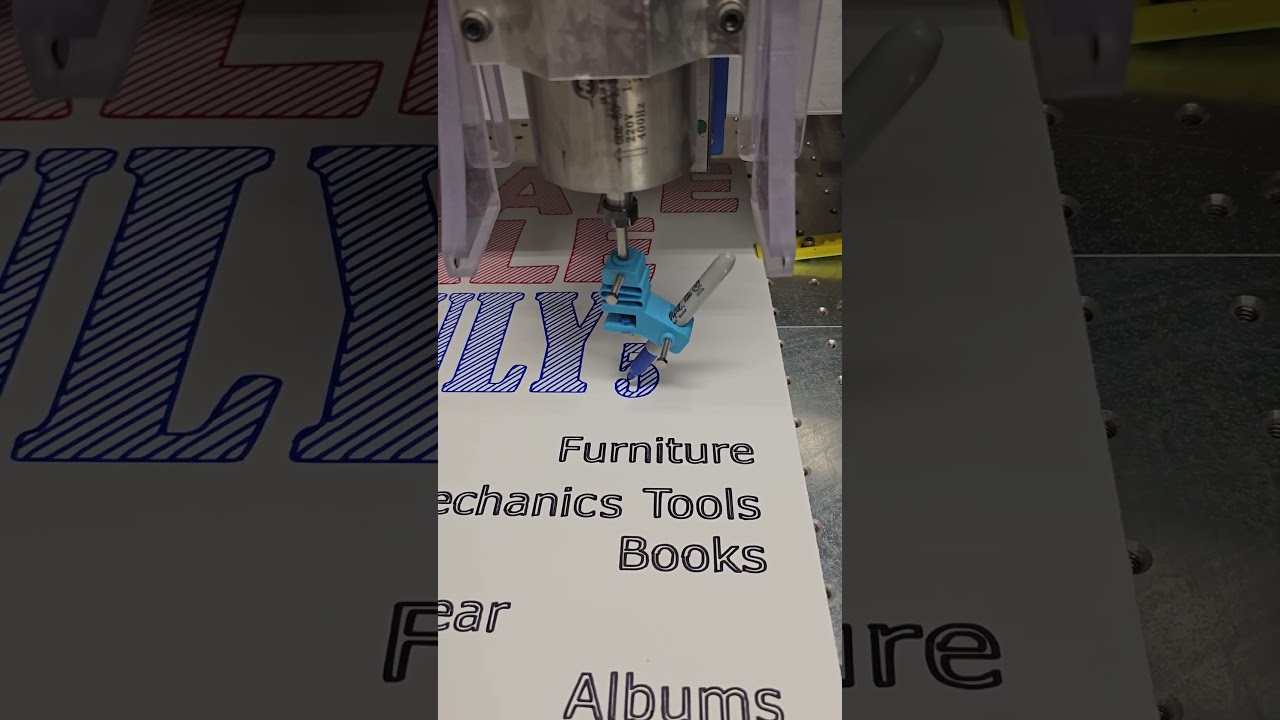

Technically, it was not cutting, but I used my SO3 XXL to make some estate sale / yard sale signs on 20" x 30" foam core poster boards.

I used Inkscape to lay out the text and imported it into Vectric V-carve and used the “simple engrave” (I believe that is what it’s called) and use a diagonal hatch fill with border.

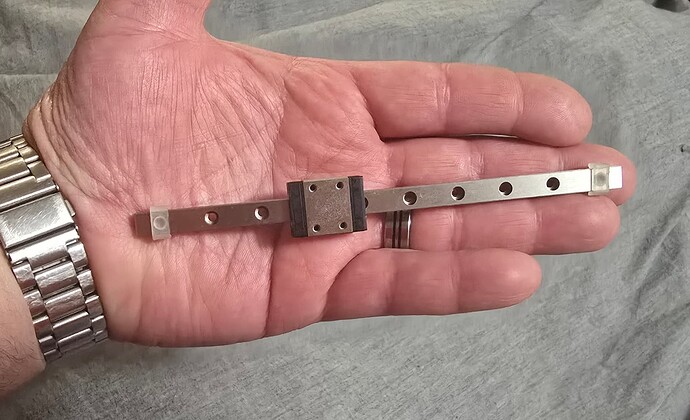

The pen holder is one I’ve had for years. It works, but it’s a pain getting the pen lined up perfectly without too much effort. So, I’m working on a ridiculously over engineered replacement using a 7mm linear rail and bearing block. If i ever get it finished, it’ll be on Thingiverse and Printables.

Look at the little fella! So cute!

That’s awesome to watch!! Thanks!

I have done some similar signs for various events. Sometimes I will offset just slightly and use a black sharpie to outline the text without any fill. I found that it helped the colors stand out especially the red.

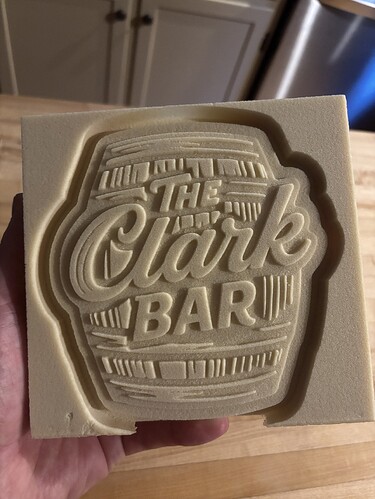

A fun one for our house. I did a smaller version first to make sure it was going to be what I wanted. We have a bar in our house that friends and family seem to enjoy coming to. So we decided it needed a logo.

ChatGPT helped with the design. Got it clean in Illustrator. Used Carbide Create to do toolpaths and a few final touches. Carved on Pro5.

I’ll do coasters and a 12" sign as well.

Not to be confused with a “Clark Bar”!!

That looks great, milled out clean and sharp. Make sure you post the coasters/sign when complete.

Careful if you are running a VFD spindle. VFDs tend to be a challenge for UPS rigs because of harmonics. I would recommend that you oversize by a factor of two or three for the VFD power.

Thanks for the info! Great input.

Something different …

I did it a while ago … it is an air duct absorber for a heat pump. It is a prototype just to check the absorption of noise with recycled PES/PU material.

Sorry for messy pictures … it is an improvised shop in an old shed …

Made on Shapeoko 4 xxl with custom 1/4 inch upcut and final pass with 1/4 round mill both 15 cm long as I was planning on making 10 cm layers … ended with 5 cm 3D carved on both sides.

I got real tired of constantly recentering and replacing soft jaws on my Saunders Machine Works hobby vise .

it’s awesome for plenty of things but I do a lot of coin/token prototyping and (in theory) a self centering vise would let me swap out coins of all sizes without re-zeroing.

Enter the Xin Dian self centering vise. A little ~$70 import that seems to be good enough. Only problem is there’s no way to hold onto it.

So I cut a fixture plate out of delrin. It fits the hole pattern on my SMW m6 Nomad bed.

The bolts underneath are fully countersunk sub-surface so they do not contact the bed. In theory this electrically isolates the vise to facilitate conductive probing ![]()

The holes in the corners are used to bolt the plate to the bed and the 6 additional holes along the side are reamed 6mm to get some repeatability by way of the SMW locating pins ![]()

Is it super rigid? No. Does it eat Z height? Absolutely.

Neither is a problem with my particular use case of very low profile, very low cutting force operations. Gotta appreciate the little wins ![]()

My daughter requested a pencil case, so I produced this for her. It’s made of walnut in the style of a bento box. I got the basic shape fairly quickly and used this project to experiment with roughing/finishing passes. The hardest bit was the magnets which hold the layers together. They had to be fairly precisely placed, which required that I surface each piece before starting the cut to ensure a very precisely controlled Z dimension. It’s finished with Osmo PolyX in satin.

I didn’t fully run this on my S5P, but there is some wording on the back of the stand that I had carved in to name this piece for the person that I have created it for.

I called it, “Mending A Broken Heart.”

My neighbor, who is an artist, brought over a wood 3D dragon puzzle and described to me how he would like to turn his golf cart into a dragon for a music festival. Makes sense to me ![]() . I scanned the wood puzzle sheets and traced the parts, scaling up by around a factor of 7. Only going to use the head and tail from the puzzle. We are getting close. He’s going to go to town now with paint, chinese pattern fabric, LEDs, a smoke machine and other decorations. Can’t wait to see the result.

. I scanned the wood puzzle sheets and traced the parts, scaling up by around a factor of 7. Only going to use the head and tail from the puzzle. We are getting close. He’s going to go to town now with paint, chinese pattern fabric, LEDs, a smoke machine and other decorations. Can’t wait to see the result.

I love it! Send the pictures of the final thing.

With a post like that, I believe he is legally required to provide a picture of the final product. ![]()

Scott, I’m thinking the only way to document the final product is with a video of it rolling down the street! ![]()

That is AWESOME! Looking forward to seeing the finished product.