Bought a 3D printer (Creality) to print some of the hold downs, trays and such. Bought a spool of PLA filament. The hold downs do not require a lot of force before they snap. Is there a different type of plastic I should be using? I understand that it won’t ever compete with injection molded hold downs, but hoping to get a little more flexibility in them.

What infill did you use?

Is your printer well-tuned to get good adhesion in-between layers?

I use PETG. It’s stronger, has the added benefit of being more suitable for the summer temps in my shop, and doesn’t have the smell of some of the other higher temp filaments.

Make sure to print in an orientation that best resists the force you are applying. The material is going to be weaker between the layer lines than across them. Similar to wood grain.

The problem I think here is that I know next to nothing about 3D Printing. Not sure what infill means, nor how to tune a printer.

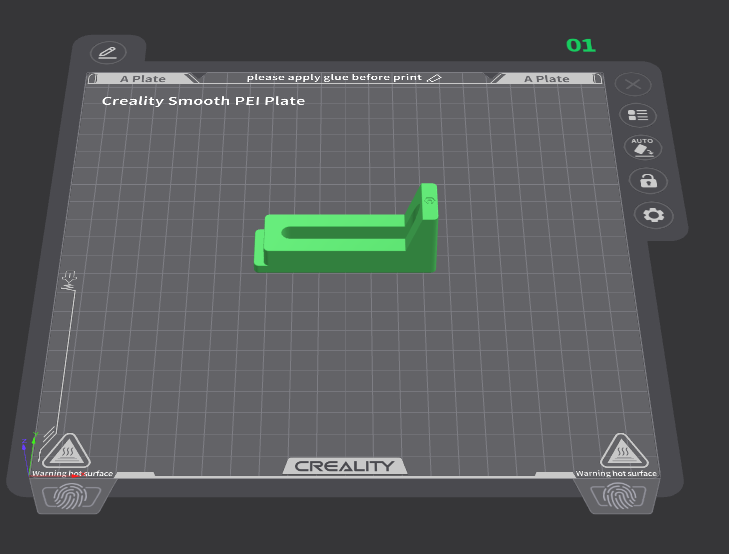

What I’ve done is try to use your essentialclamp1.stl file. I layout a bunch of them on the printers table top in the program they provide (Creality Print). Then just send it to the printer which prints them for me.

What I’ve had happen is as I tighten a project down (using the clamp steps for the proper height) the clamp separates at the lip from the body of the clamp (where the clamp comes into contact with the project) if I apply to much force on the bolt.

With regards to what Shane mentioned, these are laid out so the print head is running the length of the clamp. Don’t know if that matters.

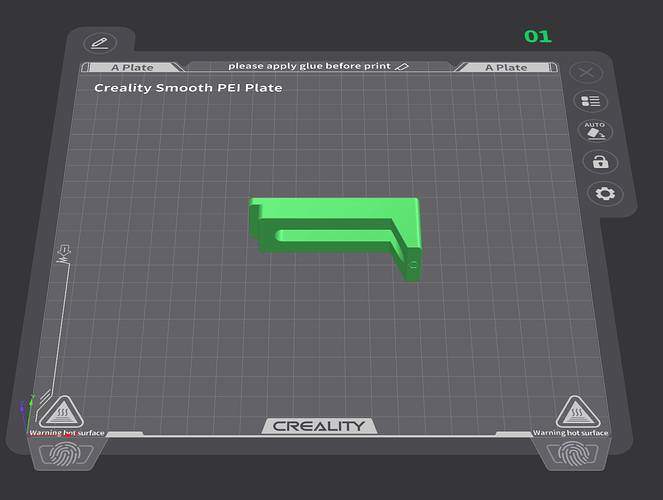

Try printing them on their side with supports, should be quite a bit stronger.

I have found with hold-downs the orientation of the hold-down is far more important than the material. 3D prints have a “grain” like wood. So you can print a part in one orientation and it is super weak. Rotate it 90 degrees in the right way and it will be strong. Can you post a picture of the clamp and I can recommend an orientation?

As @dakyleman suggested, 90° on one of the sides will be a lot stronger. You’ll have to use supports, but that orientation will work a ton better. ![]()

Thank you so very much.

I use PETG as well and it really makes a difference on these hold down clamps. The issue you might have is whether your printer can print at higher temperatures.

If your printer can print PETG, get a kilo and make some clamps. I’ve had nearly zero issues with holding down things. The PETG “squishes” a bit under pressure before it breaks and you can get them tight enough as long as you aren’t obnoxious.

When I started with 3d printing, I bought an Ender 3 v2 which did not handle hotter temperatures, so I had to upgrade the hot end. Your printer is probably newer than mine and may well handle PETG out of the box.

With PETG, infill doesn’t have to be too high, I’d say 15 to 20% is just fine. There are several different kinds of infill with different properties and each slicer has similar kinds. Gyroid infill is a favorite of mine that PrusaSlicer uses, but there are many others that are just as good.

PLA will require a higher infill percentage but you probably will not need 100% (totally solid). That can be a waste of plastic. Perhaps try 50 to 60% to start off.

In general I have found PLA to print easier and look nicer, but it can be brittle as you say. I use a lot of PETG and once you get a handle on what settings to use, it’s great. It’s far superior for outdoor use if that’s a goal for a project.

Carbide3D has a lot of their clamp models available for download and I’ve been very happy with them.

Store your PETG in the bag it came in or in an airtight container (pet food bins work) because it is more sensitive to humidity. I live in a humid area and my house is typically close to 50% RH all the time. Your mileage may vary if you live in Arizona.

I even have to use a filament dryer (not that expensive) and I feed out of it into my printers.

For what it’s worth I would go with Amazon Basic PLA when buying PLA. It’s a decent brand rebranded.

Enjoy making stuff

I use Carbon Fibre PLA at 100% infill. Rock solid. I have a Bambu X1C that has a nozzle that can deal with that. Not sure on the Creality specs.

When you 3D print hold downs, print them sideways so the layers are go vertical. much stronger and never split.

PLA will be fine. if you print it flat in such a way it wont snap on layer lines, it will work for ages

I don’t know if the following link has been shared on this forum or not, but if you have any interest in designing for 3d printing I found the following article absolutely incredible:

Not particularly relevant to the topic of this thread, but I thought people who read or replied might be interested!

This topic was automatically closed after 30 days. New replies are no longer allowed.

My 3d printer and associated filaments are in my basement, so humidity is a concern. I do run a dehumdifier that keeps things in the 40% range, which isn’t terrible but still not ideal for printing.

I had previously purchased this filament dryer from Sunlu and it worked very well:

However, my new printer – an H2S from Bambu Labs – came with their new version of the “AMS” or Automatic Material System. This holds four spools of filament and can feed them to the printer as needed. And the new version, the AMS 2 Pro, has a built in dryer. Very convenient.

Not trying to shill for Bambu, just thought it was worth mentioning.