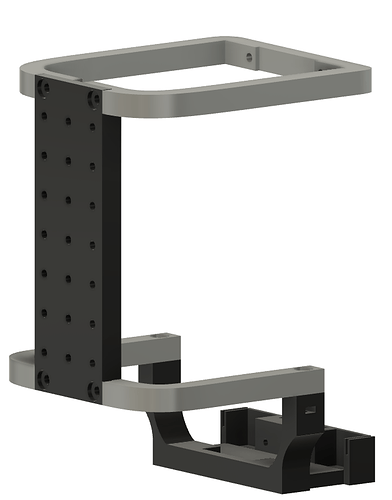

It turned out that the previous frame was too bulky for comfort, especially near the bottom where it was really not convenient when changing tools. So I went back to Fusion and designed a Mk2 version with a lot more clearance at the bottom:

In the process I learned a thing or two about what NOT to do while editing a complex sequence of sketches and 3D operations in Fusion, to go from the original design to this.

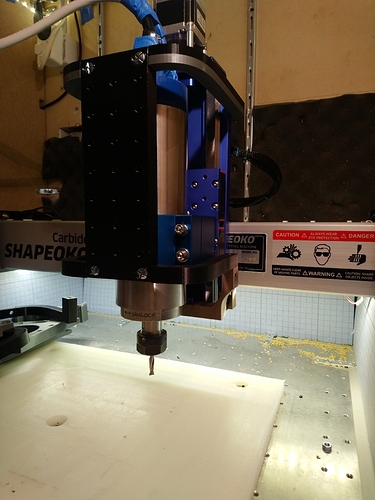

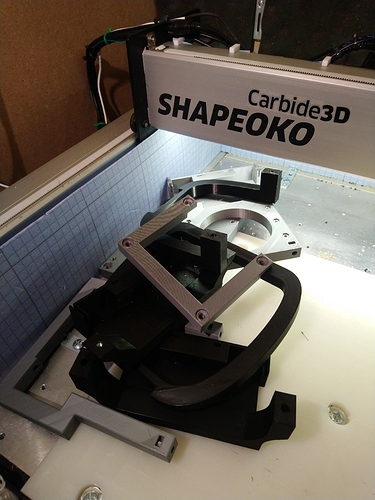

Now the frame is nowhere in the way of the spindle collet nut:

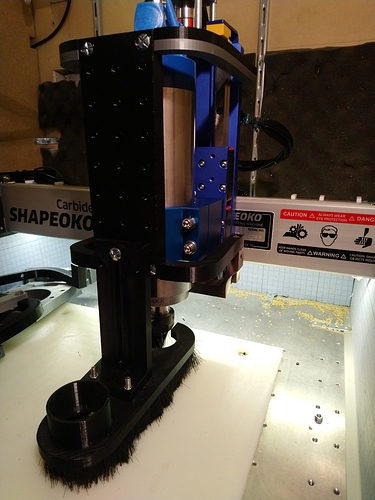

I’ll need to lengthen the arm that holds the dust shoe, and split that into one part that is adjustable up and down, and another part that holds the shoe itself, and use magnets to make the dust shoe easily removable

Most importantly I still have full X-travel capacity (designing that curvy thing to clear the Y rail was not funny though)

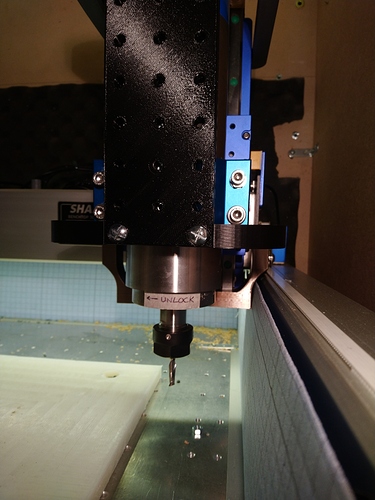

And of course I went through a number of iterations and screw-ups/reprints…