You guys asked for it! Feel free to read all this for the reasoning and exactly what I need, or ignore that and just check out the example and let me know what you think. TLDR is im using MDF and some of the islands are delicate.

https://drive.google.com/drive/folders/1xwD8igXaeCy9BBiywLROZWyYKE7ysQGP?usp=sharing

Okay! So earlier this week I made a post about larger roughing bits. I know my speeds and feeds could probably be tweaked, but I have a whole handful of complex things going on that make me think I should actually be running my speeds a bit slower. Let me explain. I’ll also upload a sample so anyone curious can take a look and maybe offer ideas

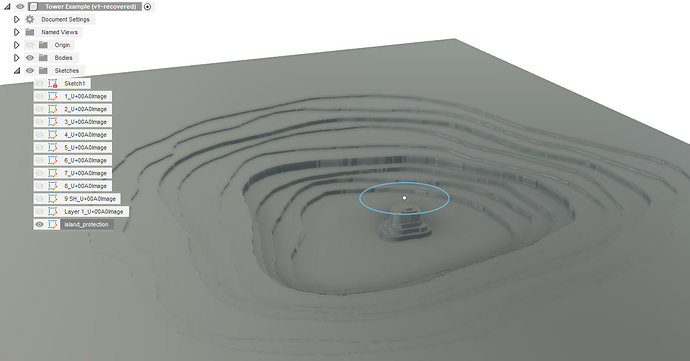

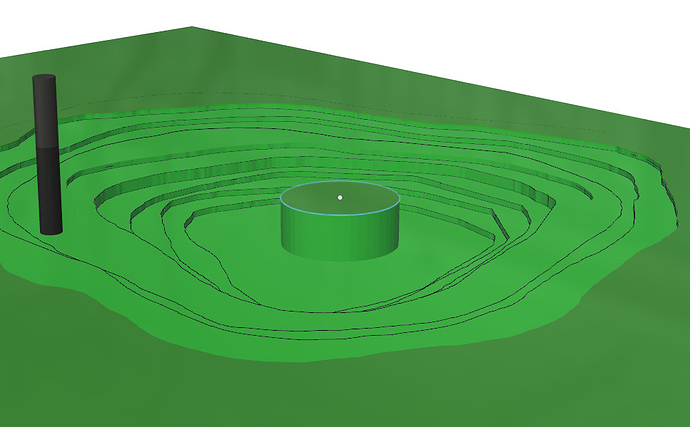

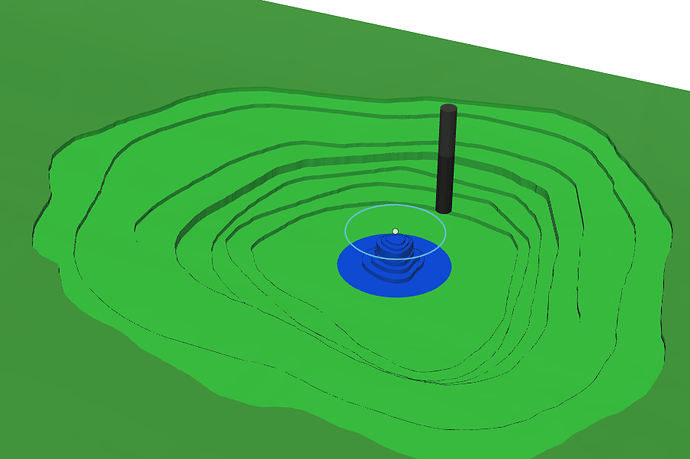

So I’m making these carved layered topographical maps of lakes and mountains and stuff. They’re made of 3/4" thick MDF.

The top layer is extruded 1mm, the shallow layer is another 1mm, then each layer below that is 2mm thick. Then I just use flat endmills and let the machine do it’s thing. On a simple lake that just gets deeper to the middle then comes back up, I can run my bits as hard as I can and it’s fine. But most lakes have shallow spots and ‘islands’ (most dont actually turn into a land island but they’re there.) If I run the endmill that hard, it carves out these islands and can snap them off.

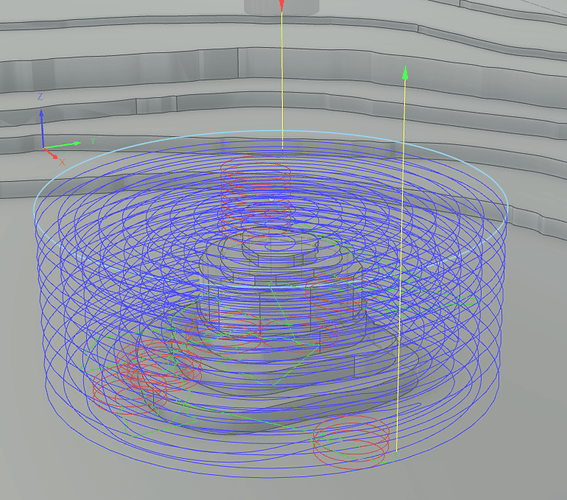

So if you click over to the design tab, there’s a sketch called “V Carve.” This is an outline of all the extremely fine details on the very top mm of the work piece. Rather than popping in a 1/32" bit that takes forever helix ramping into every single tiny detail, I trace out the thinnest details on this layer then run a v carve bit over them, it’s a nice little v-engraved effect of rivers I really like and it’s SUPER fast. And it means I can avoid the super tiny bits altogether. This is the first toolpath I run.

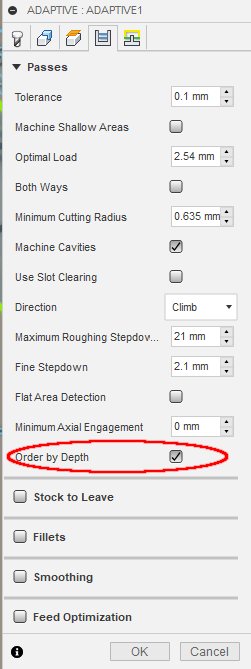

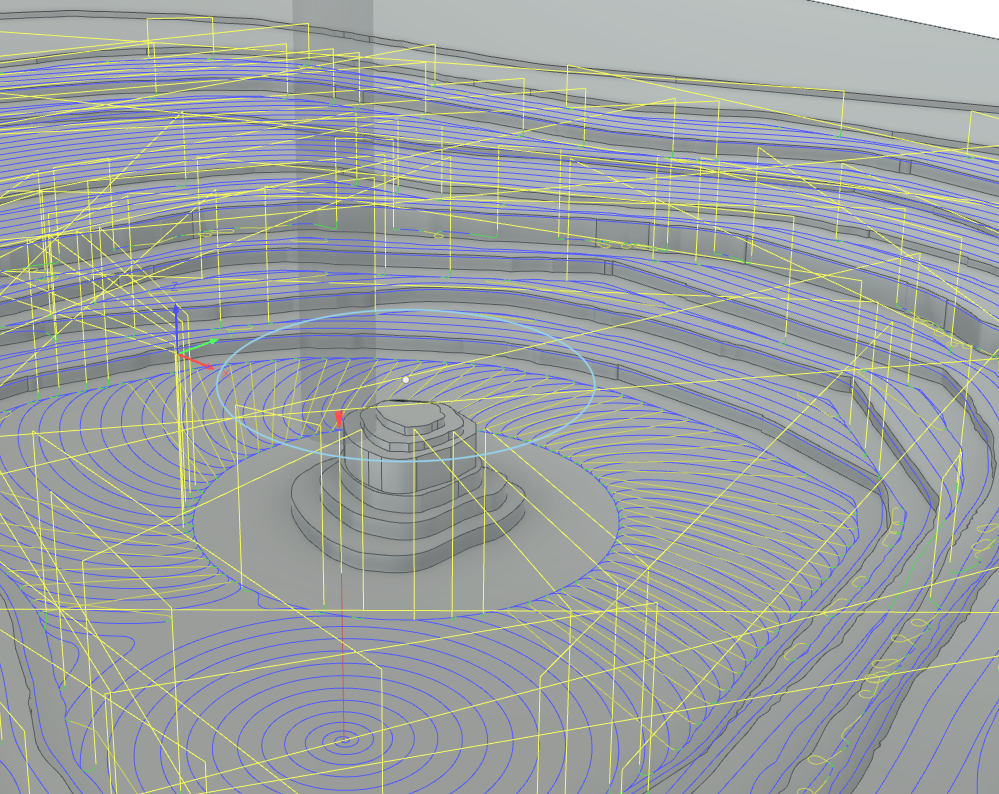

Now, adaptive 3d clearing is amazing, but if I tell my bit to go 8mm deep, any islands that come up higher than that are cut out as tall towers 8mm high. Then on future passes it shaves the top off. This is okay for beefy islands with a really solid thick base or if my material was metal, but anything smaller than 3/4 it starts getting hairy and can snap. What I do love about adaptive clearing is how it starts deep then slowly carves out working up. This leaves me with an extremely smooth finish on the bottom and the top since every step up in turn clears off the fuzzies and creates more on the layer above, but then it steps up and clears those, etc. I use upcut bits just because they’re common. I know downcut would leave me with a really smooth finish on the edges, but it’s extremely important that my bottoms are perfectly flat. (And the common thing is nice)

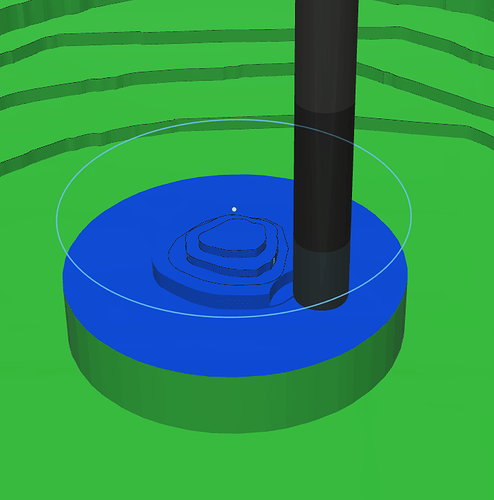

So to avoid it creating those deadly towers, I tried using 3d pocket with a 2mm stepdown(1/4" Clearance toolpath in file), it’s a lot easier on islands (not easy enough a lot though, I still get snaps) because instead of making towers, it carves out from the top and slowly shapes them downwards while building out the islands base. Think of the mechanical forces exerted on the base of an 8mm tall thin tower vs the forces on the base of a 2mm tall tower. The 2mm tall tower will obviously survive a lot easier. But since this is stepping down, there’s nothing moving along the fuzzies cleaning up each layer. I end up spending a while with a piece of sandpaper lightly rubbing each edge to remove the fuzzies and sanding MDF ‘dulls’ the edges a bit. It’s not ideal. I’d rather spend that time having it do a finishing pass to clear up those edges or something. I don’t really know how to run an ‘empty’ toolpath that just runs along the previous toolpath to clean it. Can you make a toolpath run twice without going in and editing g code? And the second pass is way faster feedrate?

I run another 3d pocket with a 1mm stepdown(1/4" Land and Shores toolpath in file) and i set the workpiece boundaries to the top 2mm of the piece just to get that 1mm land carved, and that edge is SUPER smooth with no fuzzies since you’re stepping back down and doing a 1mm cleanup of the fuzzies on that higher layer.)

Or would a good method for 3d pocket be to have stock to leave .1mm on the first 2mm toolpath, then run a second one with 0 stock leave? So the first one carves out the main shape then the second one you can run at a super high feed rate that just runs along it all shaving off that .1mm (and in the process cleaning all those fuzzies)?

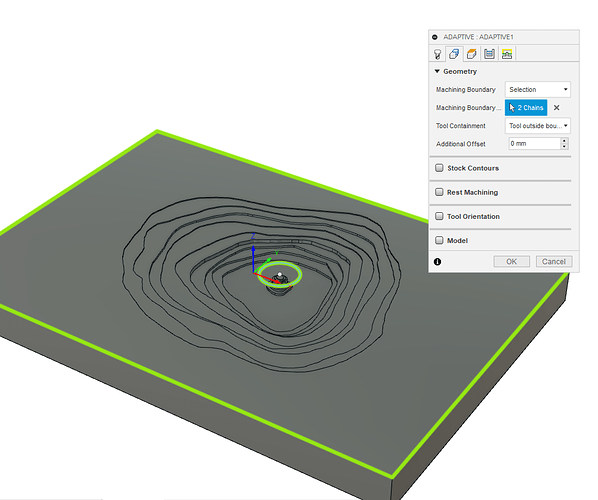

Another thing I do to further protect those islands right now is I have 2 contour toolpaths(Delicate Land and Delicate Shore toolpaths) that run first. It uses the top layer(the shape of the surface of the lake) as a boundary to work in. Then I have it offset a few mm off that boundary so it doesn’t waste time circling out the perimeter since that’s not the point of the toolpath because a future toolpath can be more aggressive with that safely. I could have a little stock to leave around the islands to further protect the super tiny ones maybe, then run a super slow toolpath on the same path that shapes them better, this way future faster toolpaths leave them alone… Or I could just run these delicate toolpaths slow in the first place). But in this one I have 0 stock leave.

So as I said, these basically circle the top few layers of those delicate islands, so when I run the 3d pocket, it doesnt aggressively run up to these islands and snap them off. Those future toolpaths use rest machining and they know the area around the islands is already cleared and gives them space, which in turn protects them. Then as the layers get deeper and the bases of the islands gets wider, the 3d pocket toolpath can hit those and usually not snap off the islands.

These delicate toolpaths kind of suck. But I tried just doing a contour of the islands themselves, but they arent model aware and if the island is within 1/4" of the land (Thats the bit im using for the toolpaths), it doesn’t care and itll blast right through the land. Whatever it takes to circle that island. Thats no good. So this is the best I could figure out.

Then last but not least, I have a couple paths that are basically the same as the 1/4" toolpaths bu with a 1/8" bit. (The two 1/8 labeled toolpaths) These guys only go 19mm deep max because the bits I have are pretty short and I don’t wanna extend a 1/8" bit much further than that anyways. (2/4" MDF is 19.05mm thick or something, but some projects I work on are on 1 1/4" thick MDF) I put a bit of leave stock on these 1/8" toolpaths or they spend an hour passing over every single contour getting those ‘pixels’ that 1/4" couldn’t grab. The main point is for them to get into areas the 1/4" couldn’t. These should in theory be pretty quick toolpaths. The second one only works on the top 2mm of the project and there’s a good amount of detail there so it can take a bit more. These seem to do really fine the way they are but if there’s an improvement I’d love to hear it.

SO that’s what the point of all these toolpaths are. So I’d love some ideas on refining these. At the current speeds (I had the delicate island circles running at full feedrate, oops…), this still snapped off a good amount of the islands. I think if I ran those delicate toolpaths at maybe 30% of the normal feedrate, that’d maybe save the islands.

Summary:

V Carve toolpath - Carves out fine details on the top layer

Delicate Land - Does a perimeter cut of the islands to protect them from the upcoming aggressive toolpaths

Delicate Shore - Does a perimeter cut of the next layer down from the land layer to further protect the islands. (I could run a third one that does one more layer down on certain lakes)

1/4 Clearance - This is the big boy, he works down in 2mm chunks clearing out the main meat of the lake

1/4" Land and Shores - Works in the top 2mm since the top and second layer are only 1mm thick, this works in 1mm stepdowns since the previous toolpath doesn’t even detect those layers.

1/8" Deep passes - Hits all the deep spots 1/4" couldnt, works in the same 2mm stepdowns

1/8" Land and Shores - Hits finer details with the same rules as 1/4" Land and Shores

The goal is to make the machining time as low as possible with the nicest finish. If I spend 20 minutes sanding fuzzies, I’d rather have 20 minutes tagged onto machining time to do it for me, obviously if there’s a way. Also this HAS to use Fusion 360, no other programs.

Here’s a link to a google drive with the files. The Fusion file then a picture of the 3d pocket fuzzies issue. I appreciate any help anyone puts into this and I’m sure there’s something to be learned here for everyone ;p

https://drive.google.com/drive/folders/1xwD8igXaeCy9BBiywLROZWyYKE7ysQGP?usp=sharing