Well, if you are worried about the exact hole locations, you can slightly oversize the holes and the counterbore slightly larger than the original MDF board so you can make sure you have enough room for squaring it up. Just use larger head fasteners or a thick washer with a tight ID. McMaster-Carr sells washers with tight tolerances.

Also, just in case you haven’t seen the other thread, Ohio Diesel Parts just started selling a 2 piece XXL aluminum base. They are making them with 5/16-18 threaded holes at 1.5in spacing. I had mine drilled and tapped for 1/4-20 since I had ~$300 in stainless steel fasteners and clamps already from my original SO3.

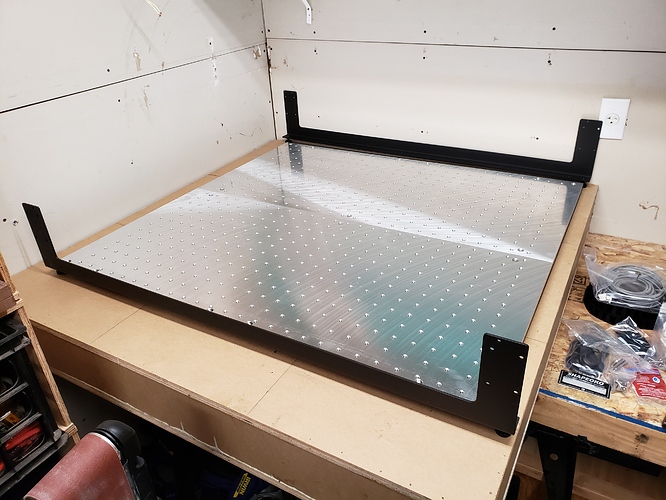

I received the base plates just the other day and I am working on assembling my XXL after having it sitting in a box for 3.5 years (long story - lack of space).

I think it is going to be a great machine after I get the Y gantry plates flipped (there is not a lot of info, but I will probably make a post to show the process and what needs to be done to make it work) to move the usable area to the back of the machine (since I am not interested in using the ability to have the spindle extend beyond the front of the machine) and get my HDZ installed with my 1.5KW spindle.