This was on the FB group, looks like one or two discussions here also, but no pictures. This is NOT my build but something Mark Jurisch did. Some of the elements were flipped around such that the cutting area on his S3 is fully over the stock wasteboard instead of some of it hanging over the front. Thought it might be worth discussing, as I know I have little use for vertically mounting boards, but would happily reclaim an inch or two of usable cutting area.

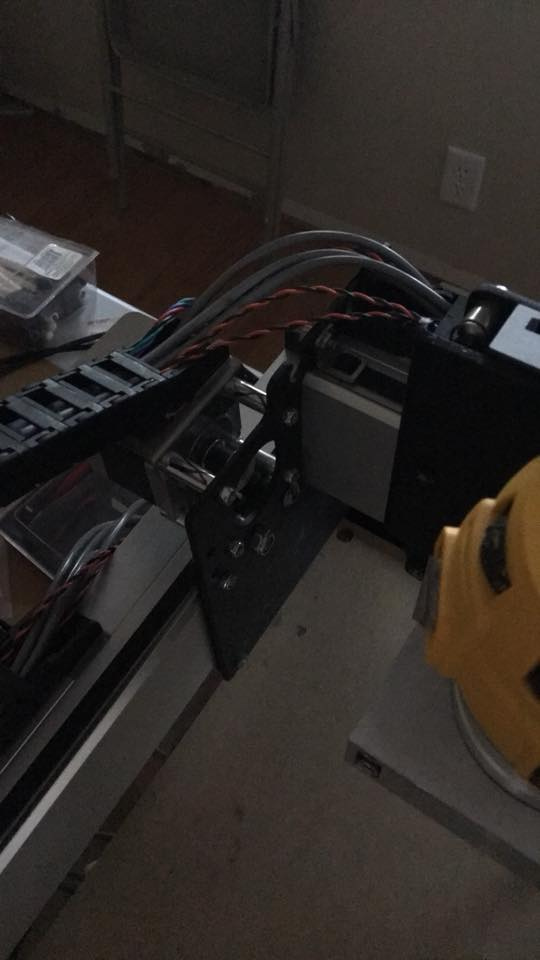

There are definitely some different ways to put it together to get different capability. Mine is put together “backwards” left and right with regards to the chains and controller to put them in a place more compatible with the space I have. I somehow ended up with a lot of extra chain and cable out of the process.

This was so interesting to me that I’ve already done the flip, but I need the spacers and longer screws for remounting the motors.

Anyone know parts sizes or part #'s or anything?

TIA

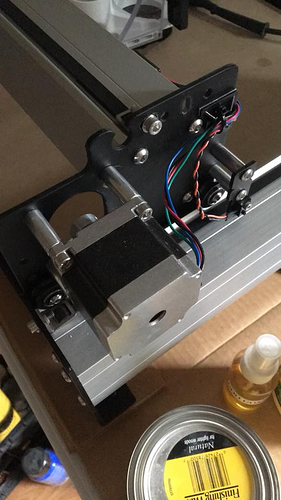

Well it looks like if I flip the pulley on each y-axis motor shaft, I can then use 5mm (ID) x 10mm (OD) x 25mm (L) aluminum spacers, along with 5mm x 40mm screws, and re-use the existing nuts.

I think the x-axis motor is already using similar hardware, is there any documentation available which would indicate the size of the aluminum spacers used to mount the x-axis motor?

The specifics of the X-axis spacer should be listed at: https://www.shapeoko.com/wiki/index.php/B.O.M.

(at one point in time the part number used was the same as the SKU at http://www.aluminumspacers.com/ )

Oh I hadn’t found that listing, the one I found seemed to have information on the Shapeoko 2 and Shapeoko 3, thanks Will!

Probably you had found: https://www.shapeoko.com/wiki/index.php/Parts which is intended as a general overview — I think when I started on the wiki there were 4 different parts / B.O.M. type pages — there are still 4, and I’ll add some links to try to make things easier to understand.

Don’t worry about it, I should have dug deeper.

I took a look at my machine and I don’t think the spacer is threaded, as called-out in the document you posted. There appears to be a longish screw going all the way through the spacer, with a nut on the end. I’m guessing it is an imperial. I might even find the same thing at my local hardware store.

Thanks for all your help, again, you always know exactly where to direct people.

I couldn’t find my post on facebook that the pictures were pulled from. If anyone has a link to the FB post (I searched for a few seconds…) there were some other details there on what else I had to do (not saying my was was the best way, I just winged it at the time) such as milling down two of the spacers to fit in the sheet metal part that supports the Y drag chain.

The spacers I used were Mcmaster 92510A649, 3/8" OD, .192" ID, 1.0" long. As best I can tell (I didn’t have any thing handy to measure when I was walking past my machine) the screws were M5 45mm Long BHCS (like McMaster 91292A195 for stainless) and I’ve replaced all the standard nuts on my machine with nyloc nuts as well.

Thanks for the information, Mark, I placed my McMaster order.

I don’t use drag chains so for me at least, I think it will just be a matter or arranging the wires so they’re safe.

Do I need to do anything special to invert the motor direction? A little googling brought me to this page:

Where it says, "This setting inverts the direction signal for each axis. By default, Grbl assumes that the axes move in a positive direction when the direction pin signal is low, and a negative direction when the pin is high. Often, axes don’t move this way with some machines. This setting will invert the direction pin signal for those axes that move the opposite way.

“This invert mask setting works exactly like the step port invert mask and stores which axes to invert as bit flags. To configure this setting, you simply need to send the value for the axes you want to invert. Use the table above. For example, if want to invert the Y axis direction only, you’d send $3=2 to Grbl and the setting should now read $3=2 (dir port invert mask:00000010)”

So I’m assuming I can just do $3=2 and I’m good? Or is there something else because I have two Y-axis motors?

You just switch the left and right connectors until they work the way you want. One already turns “backwards” and the other forward. Switch them and you’ll be fine.

Ah, good point, Mike, thank you!

Aren’t you just moving the motor forward, to the other side of the X extrusion? They’d still go the same direction.

They’re not only moved forward, but they’re turned 180-degrees and mounted such that they ride over the tops of the y-extrusions.

Oops…I should’ve looked at the pics.

@mikep’s advice is sound.

When I started this, I hadn’t realized I would need to drill new holes for the x-axis belt retainers.

So I had things mostly reassembled when I discovered this, and I didn’t want to tear down again.

So I made an alignment block to keep my drill bit positioned correctly, and drilled the new holes with the machine assembled.

But now I need to deburr the holes and things are pretty tight.

Any tips for deburring these holes?

Pic attached, left arrow points to the original two holes, the right arrow points to the new holes.

Tips/tricks would be appreciated.

Alright, someone at another forum suggested the handle-end of an old round file. I found one small enough and it make shore work of it.

This is really interesting, my cabinet restricts how far I can go forward, inverting like this would help a bunch. Especially when I attach a vacuum shoe.

Does anyone have a step by step guide? I can probably figure it out but … you know

I don’t have any step-by-step, I just sort of winged it based on what I saw in the pictures, as evidenced by the fact that I didn’t catch the need to drill new holes for the belt clips.

And when I discovered that, I had a bit of a panic attack because I knew they’d have to be placed pretty darn accurately, and I didn’t want to have to tear the machine down again. But maple block of wood drill bushing to the rescue.

FWIW, having super-sharp drill bits on-hand would have made it go more smoothly. I stopped after my first set of holes and went to Home Depot to buy a new bit (much better!).

I ordered the spacers indicated above from McMaster (92510A649) and also 40mm long screws (I used button-head to maintain a low profile, McMaster 94500A302).

I think these were my steps:

- Disconnect x-axis drive belts on both ends.

- Disconnect y-axis drive belts at the front of the machine and slip belts off pulleys on motors.

- Remove all eight wheels from the x-axis gantry. I used blocks of wood to support the extrusion. I stated by trying to remove just the bottom wheels, but you’ll still need to remove at least one top wheel to get the extrusion past the wheels.

- Remove all eight screws holding the gantry plates to the extrusion.

- Swap the left and right gantry plates.

- Reassemble the gantry plates to the extrusion with the eight screws.

- Reattach the wheels.

- Used the spacers and screws to move the motors to the outside of the gantry plates. Adjust the motors to the top of their adjustment slots to maintain clearance with the steel pulleys.

- Wrap the belts around the y-axis motors and reattach at the front of the machine.

- Go to attach belt on x-axis gantry and notice the holes have moved, go DOH! and figure out a way to accurately drill new holes. For me that meant a small block of wood and some transfer punches to make the original holes and drill them in the wood, then flip and mark unused holes in the plates that I used with 5mm screws to clamp my block to the plates. This step will vary, BTW, depending on the version of the clips your machine uses. Some belt clips have two smaller holes and require screws+nuts, some belt clips have a single larger, threaded clip.

- Reattach the x-axis belt.

- Snug all your fasteners.

- Spend a decent amount of time with magnet is plastic bag, making sure you collect all your steel chips from drilling the holes (if you drill the plates in-place).

- Reverse the y-axis motor connections, as the orientation of the motors has changed.

I think that is about it. I haven’t calibrated my belts or anything, I haven’t even turned the machine back on. I still have to re-route all my wiring (OH, BTW, I don’t use drag chains, so take that into consideration and contemplate any necessary changes if you DO use them).

Using a “very large” (ie. 2x the diameter of the hole) drill bit, just spin it by hand and it’ll deburr just fine.