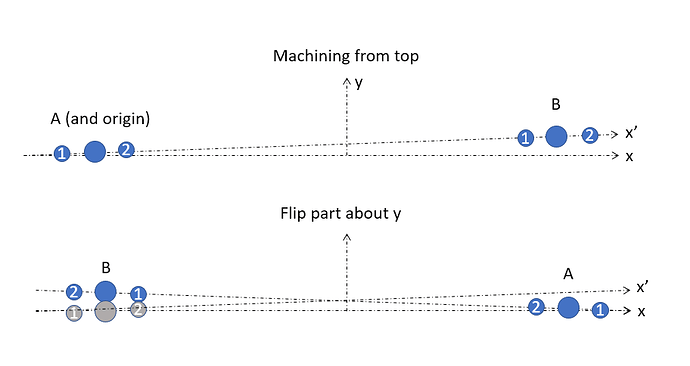

Well, now I’m psyching myself out. The origin was the center of the 8mm hole, with two 4mm dowel pins on either side for locating.

- tape + glue to machine that pattern into the board, 12in apart in x

- machine that pattern into wasteboard, using 8mm hole as the origin

- flip the part about y such that the right side 8mm hole is now the origin on the left

- re-machine both 8mm holes, but only half depth

- inspect the holes for steps

That said… I’d imagined that this should amplify the angular error between the axes, but now am not so sure?

With the original origin/locating holes shown in gray after flipping… does aligning the B side holes just put A’s holes back on x’ (meant to indicate the machine x axis, with x as the true global x that’s perpendicular to the y rails)?

Edit: I didn’t answer your width question, but hopefully this illustrates that it doesn’t matter. I was only concerned with hole locations after flipping, not anything about part width/dimensions. I’m only boring here.