I am having a bit of a problem. When I start a file to carve, the z axis moves rapidly to the top of the limit hits the limit switch so I lose the zero on the z axis. What is causing that? I have set the safe pass to .2 but it just has a mind of its own when I start the file to run.

I am tired of making kindling by having the pocket program cut all the way through the work due to z axis zero being lost. What am I doing wrong?

This is being done in Vcarve pro. The Michael Tyler cutie boxes.

Thanks, Carl

Change the safe pass height, use thinner material or chuck the bit deeper into the collet.

Thanks, I would think that .2 or approx. 3/16 clearance would be pretty low. I will try to set it deeper into the collet but am not hopeful. It just flies up to the limit and slams.

Does the z-limit switch depress?

yes it is tight at the top of the axis. I would have thought that the travel of the z axis would be slow and measured not a fast movement up to the top where it hits the limit switch and stays there. I don’t know what I am doing wrong. I am new at this cnc stuff.

Do you have the correct Z drive selected?

Carl, in Vcarve there are two Z settings. They are both in the toolpath area.

Z-Gap above material and RapidZ gaps.

Both can affect the maximum Z travel.

Michael: thanks for replying. I am not sure what Z drive you are referring to. I have the toolpath Z at the top of the material and the clearance z at .2 Is there a z setting in the shapeoko I am missing during set up. Not sure where I should look.

Sorry for the delay in responding. I live in Alaska and are time zone 1 hour behind pacific time.

Tex: Thanks for the help. I am not sure what I am doing. I have the z set to the top of the material and the pass z is at .2

Are these the ones I need to check?

Please check your safety/retract height.

See:

Hi Carl,

I was referring to do you have the stock Z or the, HDZ or the Z Plus and if the settings in Carbide Motion are set to the correct Z.

Your stock also may be to tall as stated above and retract is to high.

Hi Michael:

I have the stock z axis, not the HDZ. I am not sure where to find the correct settings in the Carbide motion that you are referring to. I have material that is .75 inches thick. I set the xy to the lower left corner and set the z to the top of the material. I zero all. When I go and run the program file, the z axis zooms to the top of the carriage and hits the stop which I am sure cancels out the z I set at the top of the material. The program runs and the end mill just keeps on cutting right through. I m new to this and am using Vcarve pro from vectric. I am trying to use Michael Tyler’s project of the month, Cutie boxes because I thought it would be a good way to get used to the machine actually doing something. What I am doing is making firewood. I just don’t know what is happening. I hope there is a simple solution,

Thanks at least for listening,

Carl

Go to “Toolpaths”. Go to “Material Setup”

Tell us what is in “Rapid Z Gaps above material”. Two values.

Tell us what is in “Z Gap above material”. Three places.

I have the toolpath pulled up and the only z value I see is the safe z which is at .2 inches. Where do I find the other values you mention? I don’t see a rapid z or z gap in the toolpaths I am looking at.

I have found the material set up and the values are set at .2 inches. Both z1 and z2 are set at .2 inches. z gap above material is 1.8. That is probably my issue. I will change it to a lower number and try again.

Thanks to all for your help. Will let you know what happens. First CNC at 77 years old.

There is some math involved with how high the top of your material is, how much bit there is exposed from the router and how much room there is when the router is fully retracted. Also, set that “1.8” to something that will clear clamps or lower your clamp height above the top of your material. Think like you are the tip of your router bit. ![]()

Well, you got me beat! ![]()

Tex:

Well I changed what I thought would fix the issue. I changed the safe Z to .75 ran the program again and managed to make more firewood. It cut through the material and when it went to the second pocket it made a wonderful straight cut across the board on its way to the new location.

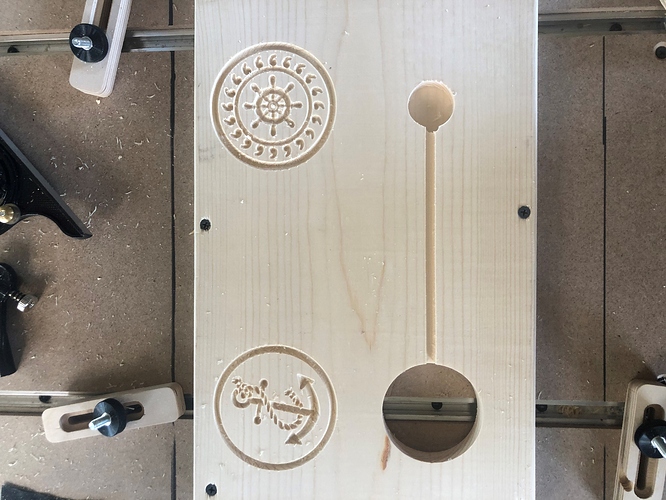

I am beyond frustrated and will just scrap the whole idea of using the vectric cutie boxes. When I do a v carve of a name on a sign I have no problems. This pocket business is not intuitive at all. I thought that if I had set the depth cut to .5 inches, it would stop at . 5, but it just kept going. ![cutie box photo|666x500] i attached a photo for everyone’s amusement. (upload://kemooKCUWg5WBRVBXZtwR1ddkYm.jpeg)

Carl, Don’t give up it will come in time. Mine did and I’m about your age. Not many on the group can fly a PA 12 but we can.

Can you post the design file and the g-code file you run?

I can have a look for any clues there tomorrow morning (or someone in a more favorable timezone can beat me to it)