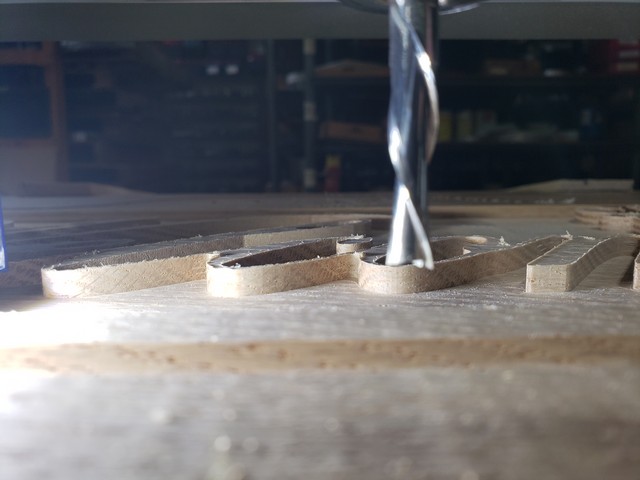

Making a sign with multiple tool changes. The v-carve is the first and it cuts okay. Tool change for 1/4" end mill to peck drill 4 holes, they all are short by ~.1".

It cut the pocket for the letters just fine using both 1/4" & 1/8" end mill setting Z with bitsetter every time.

The 2nd to last operation after the 1/8" end mill is cutting out the profile using 1/4" end mill, it cut short by about .1". Luckily I could salvage this and just do the profile cut again after rezeroing and using the bitsetter it was now going to cut completely through into the waste board, I stopped before my tabs were gone and I had nothing holding my wood.

Here is the Z axis showing it at zero position? I am lost as for what is going on.

The collet is clean and bit is in tight.

I think I may have found the problem, I need a new set of collets. The old ones have always been so loose it took 3 hands to get a bit tightened.

I can slide any of a half dozen bits both 1/8 & 1/4 and they don’t grip at all.

Here is a picture of my latest creation, doing a v-carve instead of raised letters, the bit pulled right out of the collet and I only am taking a .050" deep cut with ramps.

Are you sure you’re using only imperial bits? Sounds like you have a few bits in the metric system 1/4 = 6.35 mm and there are 6 mm bits available. 1/8 = 3.175 mm and also here ther are 3mm bits. But I gues the biggest problem lies within the 1/4 inch range?

The collets should match the endmills and tighten w/ a firm squeeze of a pair of good quality wrenches. If you are certain your collets are at fault, contact us at support@carbide3d.com and we’ll do our best to assist.

If you’re cutting a slot just as narrow as the endmill, that leads to near-constant 100% tooling engagement — best to add offset geometry (endmill diameter plus 10%) and cut as a pocket down to tab depth or the penultimate pass).

Will, thanks for that tip, I keep forgetting about adding offset geometry.

Now, can you give a simple example of this. I tried to run it and am not sure what I am doing at this stage.

Just like I have is a 1/4" wide slot that goes all the way through the wood with tabs.

Trying to wrap my head around making extra geometry and how it will affect the tool path.

Plus, for the rest of us that don’t “get it” it becomes a teaching moment !

Thanks again for all your help in our community.

Pete

See:

and

Looking at your file again, it seems to me that the endmill pulled out of the collet, digging deeper at first, and then getting pulled off course — reducing tooling engagement will make that less likely to happen.

I appreciate your time digging these explanations up for me.

Pete

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.