Did you ask about shipping costs? - Alibaba’s estimates are ~$500 to California!

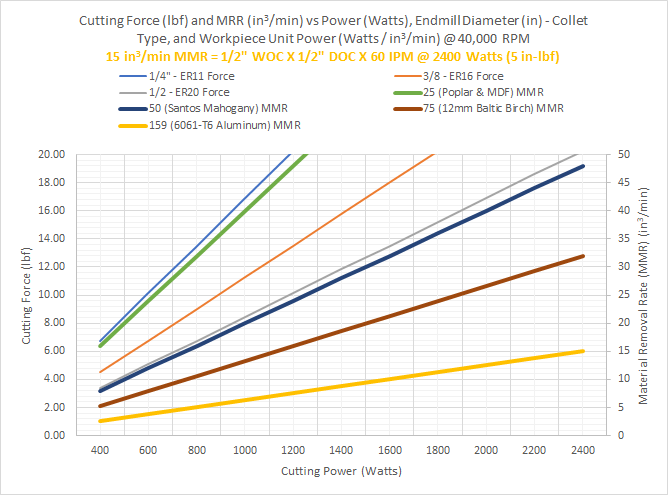

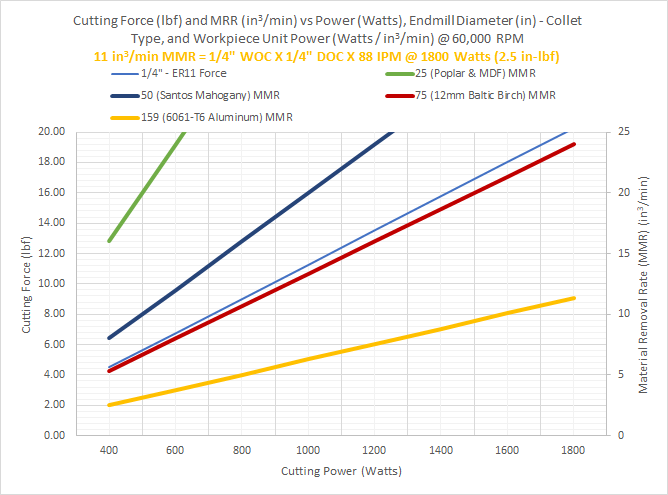

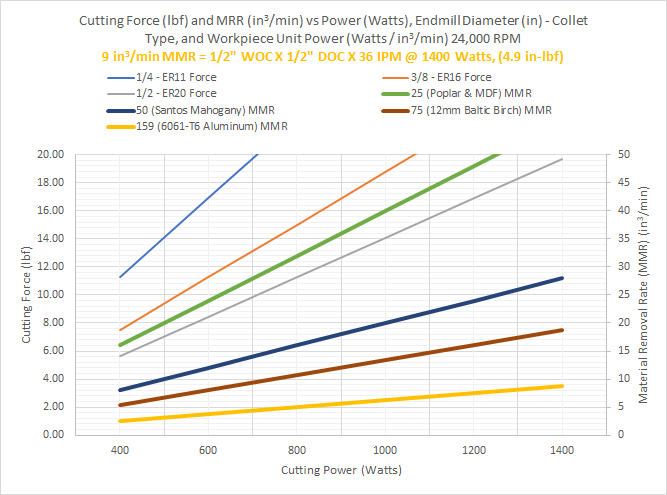

Here’s some charts to help with speed, power, and collet size tradeoffs given the 20 lbf force and 200 IPM feed rate Shapeoko3 limitations. Also note that all of these spindles are significantly heavier than the trim routers. Mr. Beaver did a lot to adapt his “Monster” (yet incredibly light weight!) 5.5 kg “2.2 kW” spindle.

The charts are in order of decreasing material removal rate (MMR) and assume that the unit power for aluminum is 159 Watts per cubic inches/min. Chip-loads are all 0.0015"/flute for the maximum MMRs. Remember that the “1.25 HP” trim routers are likely only capable of 400 - 500 Watts cutting power.