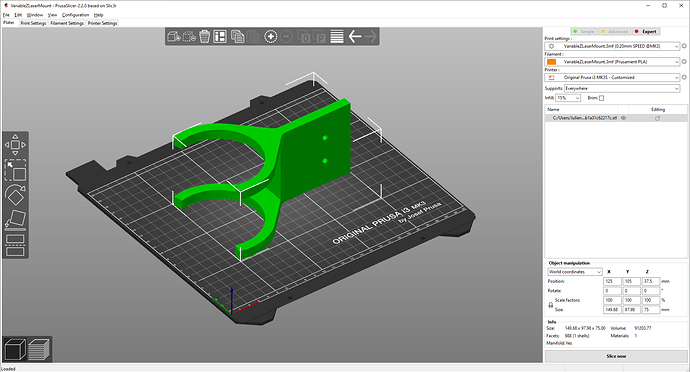

Plain PLA. There is not going to be any mechanical stress on that part anyway (the laser is so light).

I just checked what print settings I used, and it turns out I did not even bother using a lot of infill, mine was printed at 0.2mm / 20% infill

Double-check the dimensions in the Fusion model though, I designed mine for the “Blue” 80mm spindle, pre-C3D BeaverCNC era. I suspect the C3D grey 80mm mount is identical, but I have no way to check that.

Also note that this was a prototype, and whilst it worked out fine for me little surface lasering project, I did not bother finetuning it, it is possible that it’s not rigid enough for lasering very small features with high accels (a topic I discussed in that thread, when I was using a different laser mount)

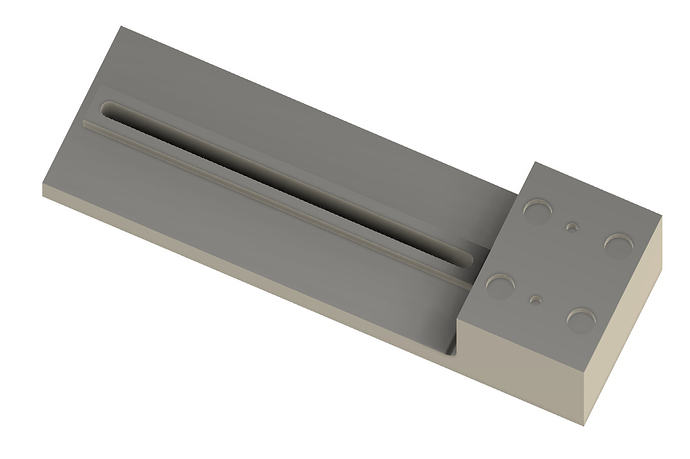

EDIT: oh and I realized that in addition to this bracket you would also need to print that other part, that is intended to have magnets, that I designed to match the JTech laser magnet positions:

That also would need to be double-checked, maybe different JTech models use different mounts.