So,

I went and found some offcuts of furniture grade 18mm Baltic Birch Ply and did some experiments with some blunt cutters, sharp cutter and a compression cutter.

The TLDR is that, if you use sensible feed rates, a good toolpath strategy and are prepared to do a little manual finishing, you can get away with surprisingly blunt upcut cutters.

I found the fastest way to tell if the cutter was still sharp was to carefully and gently run my thumb across (not along) the cutting edge near the top of the flute and then again in the wear zone near the tip of the bit, they feel very distinctly different on a used blunt cutter.

Cutters

These are the cutters I used

- The used, abused and fairly blunt Carbide 201 3 flute upcut with the close up pics in the previous post, not saying anything about the Carbide cutter here, just it’s age and how much wear I’ve put on it going through a lot of MDF and birch ply

- A used, abused and almost as blunt Yonico 2 flute upcut (cheap cutter, surprisingly good)

- A new, sharp Yonico 3 flute low helix upcut

- A new, sharp Yonico 3 flute compression cutter, 6mm upcut, remainder downcut

Toolpaths

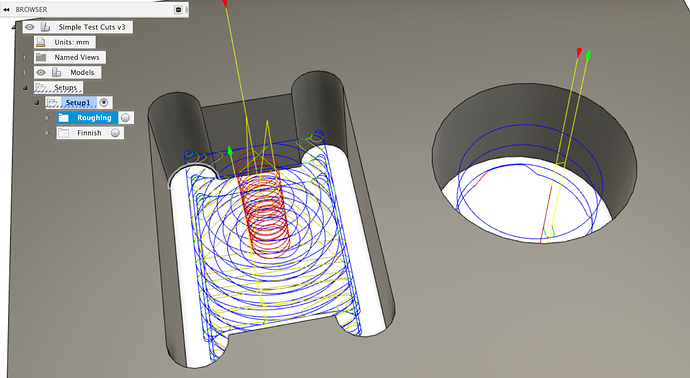

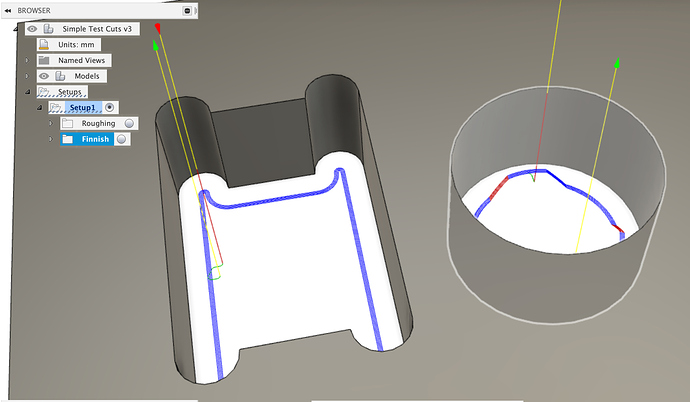

I drew out a couple of shapes similar to those being cut by David for a test in the offcuts I had, the cutting strategy was to first rough out the bulk of the material in 6mm depth passes at 1500mm / min feedrate and 20,000 RPM, the shape with an adaptive clearing strategy and the circle with a full engagement contour cut, both of these were set to 1mm of axial stock to leave;

Those cuts are not fast or particularly heavy engagement, the idea is to test finish quality not MRR.

I then came back with finishing passes, 4 stepovers of 0.2mm each at full depth to bring the walls to final dimension;

This allowed the full depth of the cutter to engage, including the still sharp parts of the used blunt cutters and provided a good opportunity for the finishing passes to clean up the hairies from the roughing cuts.

Blunt Carbide 201

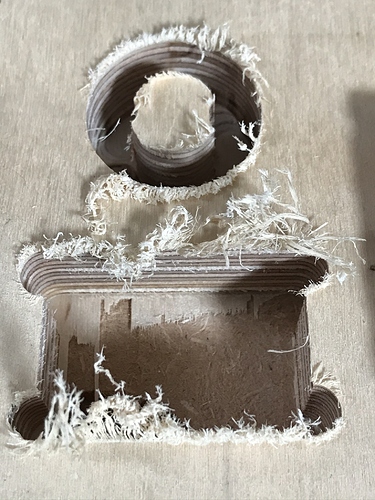

The first test cutter is the blunt Carbide 201, here’s the results of the roughing pass;

As expected, it’s a mess, there was no substantial chatter or vibration, the XXL used has an HDZ and 2.2kW spindle, new belts and is reasonably tight. The hairies are along the grain of the top veneer as expected.

The results of the finishing pass are below;

That was disappointing, the hairies have been thinned out, especially at the base, but even taking another 1mm off the walls in full depth finishing using the sharp parts of the cutter didn’t get rid of the fluff.

Blunt Yonico

Next up is the blunt Yonico upcut, below is the result of the finishing pass, not much different to the blunt Carbide and any difference is likely attributable to wear;

Sharp Yonico

Next, the new, sharp, low helix upcut Yonico, this I expected to do better both because it was sharp and also because it was lower helix so more shearing and less pullup on the material;

Compression Cutter

Finally, the compression cutter, the roughing passes were done with the sharp Yonico low helix and then the full depth finishing passes were run with the compression cutter (I even remembered to re-probe the Z);

That’s a lot closer to the finish I was hoping for.

But Wait!

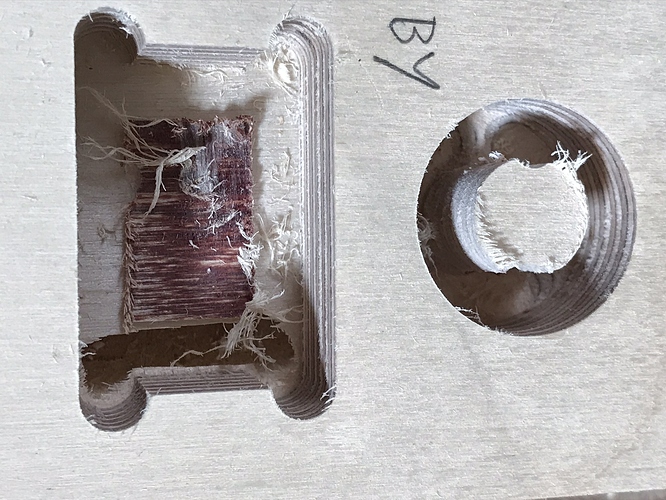

Last thing, I went back and took the flat side of my marking knife to all the pieces to trim off the hairy bits;

And the results are;

Blunt Carbide 201 Trimmed;

Blunt Yonico Trimmed;

Sharp Yonico Trimmed;

Summary

Which all suggests to me that with a sensible roughing / finishing toolpath at a sensible feedrate and a little careful finishing you can get away with upcut cutters and even quite blunt upcut cutters.

The compression cutter undeniably leaves a better finish straight off the machine and needs less work afterwards, but you have to use it in quite deep passes, preferably at full depth as a finishing cutter. I’ll be using this cutter for finishing on pieces that I’m not sending the chamfer cutter round from now on I think.

After a little sanding I’m really not sure I could tell which cut was which without the labels.

This doesn’t mean you can get away with cutting with an old cutter blunter than Brie, there must be a tipping point where the cutter is doing so much damage to the top and bottom veneer that it’s not recoverable.

There are also plenty of other ways to get an ugly cut, workpiece vibration, excessive depth of cut or feedrate, loose V wheels or belts, etc.

HTH