I need help understanding tool paths on a waste board. Do I leave it as is do i contour? I don’t think I’m ever going to figure this out.

In Carbide Create, create a box the size of your cutting surface. Then in contour, select pocket where the options are pocket, no offset, inside and outside. Set your cutting depth to however deep you want to take off the top.

ok i downloaded a file from here for a threaded waste board, isn’t it just a series of holes?

Dennis:

There are two operations that are performed on a threaded wasteboard.

The pocket operation is used to flatten it using a mortising bit.

The holes you refer to are for threaded inserts (inserted from the top) or T-Nuts inserted from the bottom. Those holes are made using a 1/4" end mill.

What file did you download ?

If this doesn’t make sense ask other questions. It can take awhile to get the hang of this stuff.

Bill

it was on here suggested by will Adams for the xxl

ok can it be modified to just do the holes?

Dennis:

Check out this video. He does an excellent job of explaining the steps making a wasteboard.

How to make a Wasteboard for a Shapeoko XXL

I was lucky enough to come across this video when I first got my Shapeoko. About 1:50 into the video he refers to ‘bottom wasteboard’. This terminology has lead to confusion. The bottom piece of MDF is the base of the machine. It is NOT a wasteboard.

He uses T-Nuts from the bottom which are not prone to being pulled out.

He also offers the file used to create the wasteboard as a free download.

What kind of router do you have ? If you have the Makita things get even more interesting (confusing). Let us know.

Bill

Dennis:

Do you have a BitSetter ?

When the video from Ben Meyers I mentioned above was made the BitSetter was not on the market.

If you have a BitSetter please be sure to remove it before surfacing the wasteboard because you will hit the BitSetter. Not a happy event.

Bill

I worked through bootstrapping a supported cutting area — even if you’re not planning on doing that you may find it a useful review of moving around the machine and planning a cut:

Thank you yes I was looking at that one. I don’t think I need 250 holes was just lookin for something simple that doesn’t take 20 hours to make. I’m new to this and everything is starting to get complicated and I don’t want to be that guy who said I made a mistake in this purchase.

Just so you know, there are a lot of options for workholding, and one of them does not require drilling any holes: using painter’s tape and CA glue. Here’s a quick overview, for you to check if this could be of interest to get you up and running, and decide later to mill a fancy drilled wasteboard once you are familiar with the machine and the CNC process.

I have several clamps made with the Shapeoko XL (and even four from Carbide3d) but I have become fond of super glue and masking tape.

Excellent suggestion by Julien.

Bill

Thank you for the reply but I have seen a lot of post about that. People say it pulls up and ruins their projects and bits. Just looking to do it right to not mess up my machine. I have a 40watt laser as well and didnt have this much of a learning issue.

Those people don’t do it right, I’ve never had this happened to me, if anything I sometimes struggle to remove the piece after cutting ![]()

Same experience for me. The only securing method I’m not as big a fan of now for certain jobs is double sided foam tape. When doing throughcuts the bit will grab the foam tape and spread adhesive over the stock, which is a pain to clean after it’s been heated and pushed into the wood grain. I haven’t had a part release from the wasteboard with any of these methods though.

FWIW, my decision for the next time that I have to revisit workholding is that I will have a 3 layer system:

- structure/bottom: original MDF baseplate (sealed with spar urethane or lacquer) with some holes and threaded inserts installed from underneath for adding points to secure from above — a replacement of the original may be easily fashioned by sourcing a piece of MDF, removing the original, clamping it to the blank and cutting it to size and transferring the holes using transfer punches, drills, and countersinks.

- workholding/middle: a threaded insert board no more larger than the working area by the reach of a clamp (but, see below) which has holes in that border area which match up with the threaded insert holes in the bottom layer to secure it (making it the same size as the working area may be simpler), a grid of holes in the working area field for threaded inserts installed for workholding, and additional holes with threaded inserts to secure — discussion of bootstrapping this at: Notes on rapid positions and wasteboard leveling

- spoilboard/top: a sacrificial cutting material the size of the supported working area plus the diameter of the endmill used for surfacing along X, and endmill radius along Y, (with a matching radius at the back corner) which has holes in it to match the threaded insert board for workholding purposes (these may be drilled at need) and holes to secure it to the threaded insert middle layer. Wasteboard Plans with threads

and the middle layer will have new holes for threaded inserts drilled into it and the spoilboard from the top on an as-needed basis using a master file run on the machine — then removed, and the hole drilled through, then enlarged from the other side for the threaded insert — that way I know each insert will get used at least once.

When using super glue and tape I use a straight edge to position the workpiece over the blue tape on the spoilboard. You could use pencil marks as a guide as well - just don’t depend on your eyes.

Any glue squeeze out (not on the tape) will cause unhappiness when trying to remove the workpiece.

Bill

Good tip. I’ve been pretty careful with the glue as I don’t want the squeezeout issue either. The difficulty removing is probably more from the linear footage of tape I used (maybe too much?) which can make getting leverage to “pry” it off tricky.

Thank you all for the Tips and advice and your experiences with tape will be giving it a go for now.

Edit… seems less relevant now… I’ll leave it here though

I started with zero experience too, it will get easier just keep asking questions.

This is how I’d do it:

- Jog your machine around to the furthest extents on all corners, mark the corners with a pencil and measure the size of the square, from memory its roughly 31’x31’ for the XXL. This is your ‘work area’

- cut a piece of 3/4 or similar MDF to the measured size. Drill some holes and countersink them half the depth of the board and screw it to your bottom mdf boad/machine base. This is your ‘wasteboard’

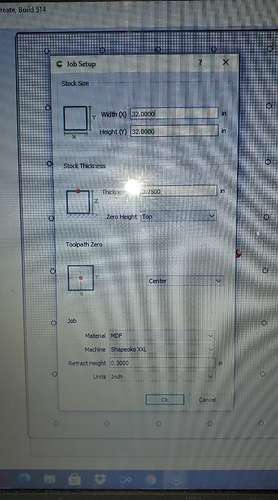

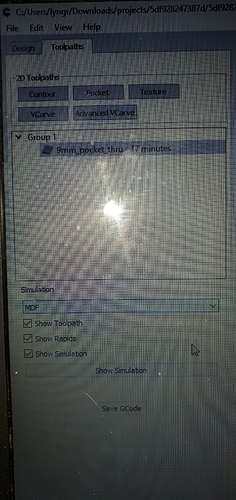

- in carbide create, draw a square the size of your wasteboard, and create a ‘pocket’ toolpath with the 1/4" flat endmill, maybe 0.010 deep.

- zero your machine, ensuring it matches what you set in CC, and run the job. if the edges don’t quite clean up, grab a file or plane and smooth them down or make the square in CC slightly bigger if your machine hasn’t quite maxxed out its travels

when I got to this point, I spent a month or two using the slotted style clamps like Like these with a screw into the mdf wasteboard. this does rough up the wasteboard but I just sanded it between jobs and it stayed relatively flat while I learned how to use the machine. this will also give you time to decide if a threaded wasteboard is for you or you want to try t-track or something else. A lot of people (myself included) use the masking tape and CA trick with success. some jobs it’s great for, others clamps work better.

- When you’re ready, use the wasteboard file above to drill holes for threaded inserts, watching for the screws you put in to hold the wasteboard down. the above file is just a bunch of circles. you can use that file or redraw them however you want. a google of ‘threaded wasteboard’ will give you some ideas

If you want to run with t-track, cut a bunch of strips of 3/4" MDF 3" wide (can be any size) then screw down the t-track to the base with the strips of mdf in between. make sure the t-track sits lower than the mdf so you can surface it. if you use the same with strips its easy just to cut a bunch and replace them

Similar to this

I bought the 40w laser after the shapeoko… definitely simpler to get started on, once you get comfortable with the shapeoko (which you will) the laser and cnc really complement each other