Yea, that is a French Cleat Wall. That was right after i built it. I had the cleats for the tool holders placed in the cleats on the wall to keep them from getting bowed while i was making tool holders.

We’re looking at adding a lot more rendering options in V7, but we’re still working through the technical and user interface problems so I’m not sure what we’ll end up implementing.

- (NEW) Polyline tool shows angles and length of prior span to help build construction geometry.

Looks a lot like the measure tool. Nice

- (FIX) Clean up left pane scroll behavior.

Works perfect now.

- (FIX) Trace command updates. (Had it fixed, then broke it in the prior build)

Nice. Much quicker to dial an image in.

- (FIX) Allow a second click to lock the positions in the Measure command.

Also nice. This is intuitive & easy to use.

- (FIX) Disable snaps on hidden layers.

Still some situations where it would be nice to toggle off “Snap to node” similar to “Snap to grid”

I could probably live with inconvenience of a web page G-code extractor. That said, this appears to be a treatment for the effect, not the cause. If the issue is support, why not set up a web page restriction for support, instead of a page for G-code export?

I, like others, was deeply disappointed in the message sent by removing the ability to generate G-code. I understand the concern about folks using CC on hardware not sold by Carbide Create, but that was part of the appeal. A company truly so open was refreshing, and the youth of the home CNC industry means there is no guarantee any of the current manufacturers will exist long term. Has anyone considered the significant downside to the company and to our community of all the non-C3D folk who most likely will abandon CC?

In the interest of full disclosure… My Shapeoko 3 was the smallest version, and I found I needed something a bit larger. So I now own a second machine that is not from Carbide3D, but continue to use my Shapeoko in parallel (which was no small decision, since I am really space bound). Not only would I like to use one CADCAM system for both machines, but I have also discovered past CC bugs by reading the G-Code and on a couple of occasions have needed to edit G-code. A proprietary file may help work flow, but the cost is too great for me.

I didn’t read the problem as this at all. I thought it was non-customers using support that was the issue.

Not non-customers using the software. ???

So the problem/opportunity statement should be, “How do we limit support to only our customers, or at least give customers priority over non-customers?”

Which leads into the first question, “How do we identify customers vs non-customers?”

I have a login on my.carbide3d.com, as well as here on the forum. I provided my email when I bought my machine. Seems there should be a relatively easy way to make a connection. ??

If you interpreted my comment to mean that C3D employees were concerned about non-customer use of CC, I’m sorry. That was not my intent. However, there have been postings by others on this forum that I interpret to imply such concern. More importantly, the proposed solution applies to non-customers and not specifically non-customers seeking support …which was my main premiss. Regardless of whether anyone worries about non-customer usage, I see the elimination of G-code export as potential collateral damage by reducing the size of the user community, as well as tarnishing the C3D corporate image in the eyes of those of us who value open systems.

Hello, Many good feature improvements and new features. However, I have submitted multiple requests to have previous version of CC fixed so a .dxf file is opened with the correct scaling. I have submitted detail examples of why it doesn’t work correctly. If you open a .dxf file that is scaled for inches, the object vectors of the .dxf file are scaled to mm and visa versa. Why can’t this be fixed in CC V7. These example files open correctly scaled in other 3rd party CAD software like LibreCAD. Seems the vectors should follow the scale settings in the setup panel. You want the file job setup window set to inches, then all the vectors should be scaled to inches. The way it is now, you get tiny vectors that are 25.4 times smaller than they are supposed to be. This seems like a simple code fix to resolve this. Would hope this could finally be resolve in one of the upcoming V7 versions.

Yep. Especially this of us who do drag engraving, at least with non-Carbide bits. The software still forces you to edit out the M3 commands in the gcode. This plus Rob’s suggesting I get a raspberry pi or Windows laptop to run the new version of CM which will be required.

Is the idea here that former freeloaders will now rush to buy Carbide machines?

Zero RPM for Contour toolpaths is on the TODO for V7

For the user above that has a really old PC, and is currently running an old CM, this might be the case. There’s nothing in this new CM that should trigger the need for a new PC compared to the prior build. It just added the loader for C2D.

We have zero expectation of anyone buying a C3D machine from this, I think most will continue to use V6. There’s no killswitch in CC, and there’s no cloud tie-in at all, so V6 will continue to run as-is for a long time.

I just created a new project. The project is to hold my new Bridge City Tenon and Kerf Maker gauges. My question is in previous versions in the toolpath you would save your toolpath/toolpaths but still had to save the c2d file separately. In the Beta 7v if you save your toolpath/toolpaths you save them to the original c2d file or a new c2d file but it appears to me even if you select “Toolpaths only” you get a file of the exact same size as the original c2d file. So is saving your toolpath the same as going to file menu and saving the c2d file? The only difference is if you pick “Save toolpaths in this file” or “Save toolpaths to a new C2D file” you wind up with an identical file with different names if saving to new c2d file.

So is saving toolpath same as save/save as in file menu the same thing?

Pretty much. The Save Toolpath button doesn’t appear until the toolpaths are done calculating so you can be sure that the toolpath data made it into the file.

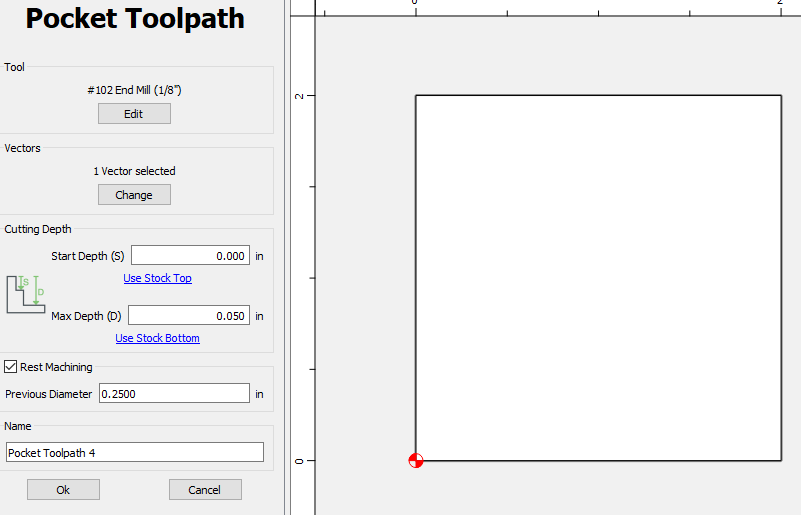

Build 710, with the first pass at Rest Machining for CC Pro is up at https://carbide3d.com/carbidecreate/beta

Look for the option in the Pocket Toolpath settings.

Woah that was quick. When you said a week or two ago it was on the docket, I thought that was 3-6 months out. Gonna have to put that to work soon.

Edit: Is this a pro-only feature? I’m not seeing a difference in the Pocket toolpath settings from 6.x.

Feature request - see inches / metric at the same time for tools in the tool library selector. Right now it is inches only. This could be coded in minutes.

So for example, under Geometry, instead of this:

Diameter: 0.125 in

Show it as this:

Diameter: 0.125 in / 3.175mm

Etc for all the cutting parameters.

[Edit: Ruh roh. The first PC I installed it on has Windows 7… I know, I know. I installed it on a Windows 10 PC and it looks normal.]

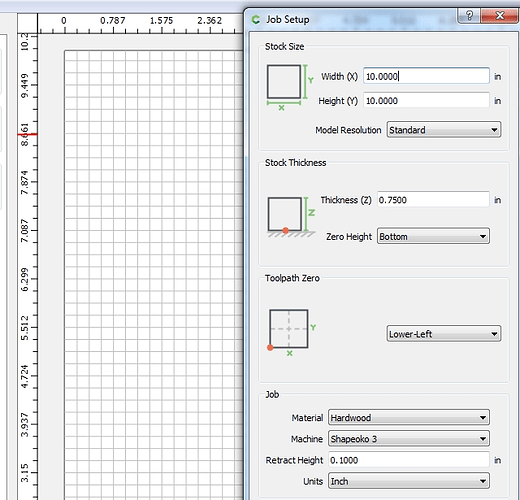

I installed CC 707, then 708, now 710, and my work area ruler looks like this with decimal fractions of an inch. I uninstalled and reinstalled, same thing. I changed the stock size, numbers don’t change, just get closer together. I changed from mm and back to in, same thing. Any ideas?

What is your grid spacing. Is it possible that t he rulers are tied to the grid spacing?

I can understand this point of view, but it seems based on relatively recent history.

It’s prudent to remember that CC had propriety GCode that only worked on Shapeoko machines in until July 2017, where they decided to open it up to others and added plain GCode (often this is great a marketing strategy and a good source of testers and ideas for any fledgling bit of software). It’s also worth noting that they probably won’t do things add STL’s to CC Pro because the guy in charge of CC also owns grzsoftware, which makes MeshCam which does do STLs. So this is a business, not a service, and they are doing what businesses do to try to get you to buy particular products and keep you as a customer.

You guys are cranking these out!!! ![]()

Each tool is stored in the unit in which it was created. You can see both Inch & Metric tools.

Yet the .c2d files are all stored in metric, and if the user chooses inch the UI converts it.

I think the latter is the smarter way to go. Then just move the selection for Inch/Metric to the main menu, so the user can change quickly.

Not a programmer? ![]()

Downloading latest version now. ![]()

Rest machining with the default settings results in an empty toolpath. (.25 previous tool, .125 tool)

Changing to a smaller tool or larger previous tool works.

- (NEW) Rest Machining for CC Pro. (Need a better error message when no toolpath is required)

How about “No Toolpath Required” ?? ![]() (The yellow highlight works for me)

(The yellow highlight works for me)

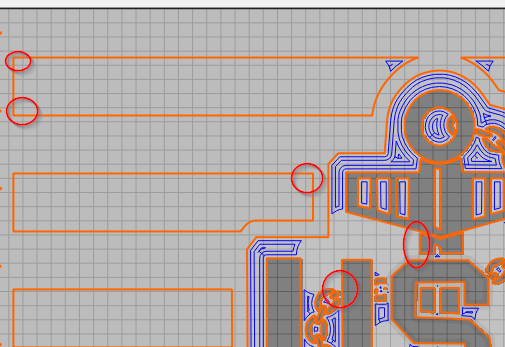

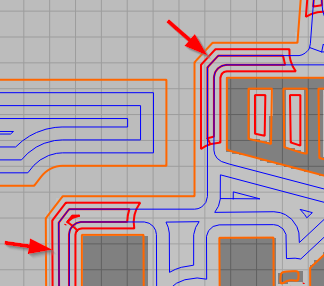

It’s also missing some areas

Anchor Flag 3d try 4000.c2d (1.3 MB)

And it’s doing some redundant cutting, where it should only be picking out the corners

Would it be prudent to create a new topic for each point release? 140 replies, and I’m predicting a lot more… ![]()