After using the V8 Beta for awhile now. Im liking it very much. BUT still have to issue of the if I try a Vcarve. It doesn’t break it up into 2 files like a inlay plug does. Will or can this be remedied. I have tried to write the code to send it home after the initial pocket cut but can’t seem to locate the correct spot in the code line to do so . Any Ideas? Thanks in advance

Upload a file where the V carving doesn’t split into two toolpaths which may be output separately in v8?

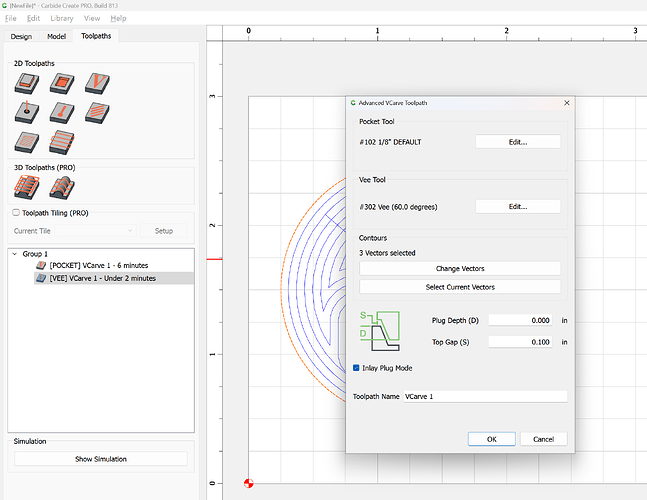

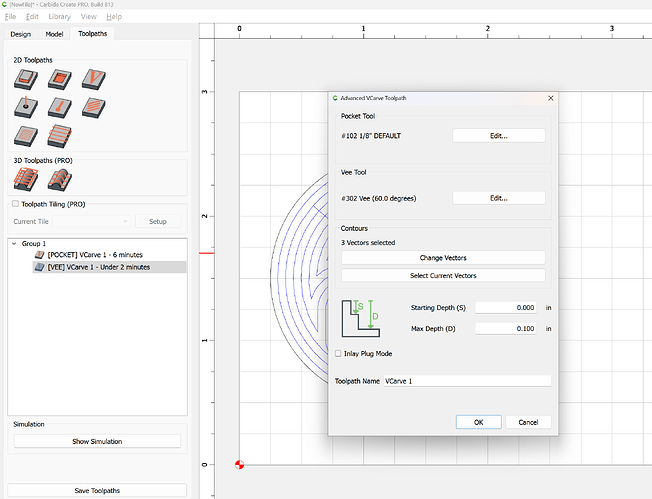

When I do a Vcare inlay it keeps the pocket file and the VCarve as one file. As when I do a Plug inlay it keeps each file separate if that makes sense. I don’t own a machine made for Carveco create. I built my own. So Its got this little glitch It wont return to home or start X,Y,Z, Zero after the pocket clearing. it lift up a little then stops. Im unable to swap the bits. I thought I figured out how to fix this issue. I still might have But Im would consider myself still a learner when it comes to the code tampering, changing. Adding Ect. I figured out if I remove the M05 code from the G-code I can keep it from shutting off my machine. So I figured I try and find the spot where it stops and input a command to send it back home for a bit change. Not sure this is making sense. But got to try. Thanks

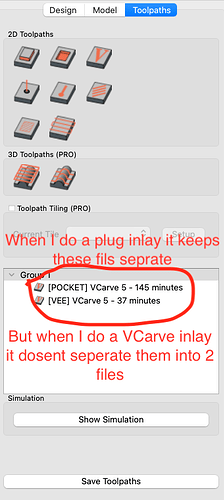

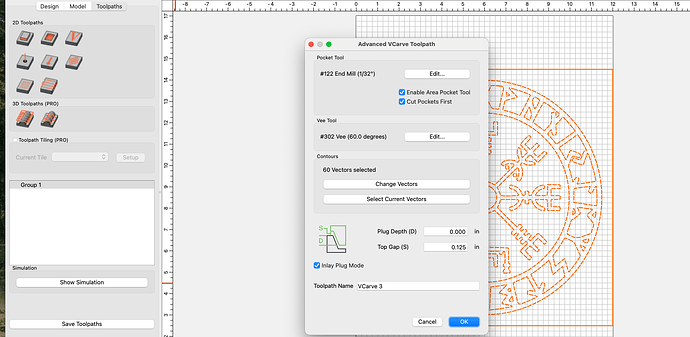

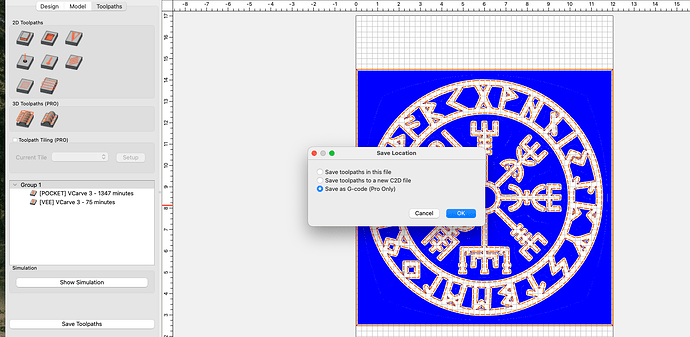

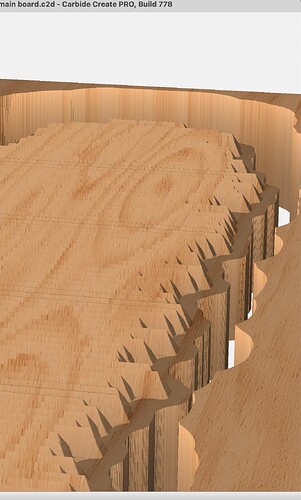

If I do Plug mode I get two files:

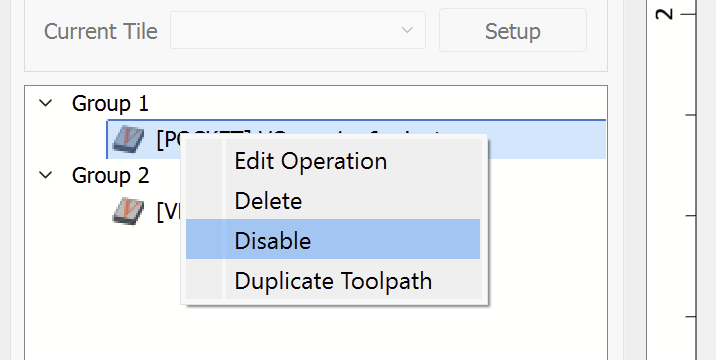

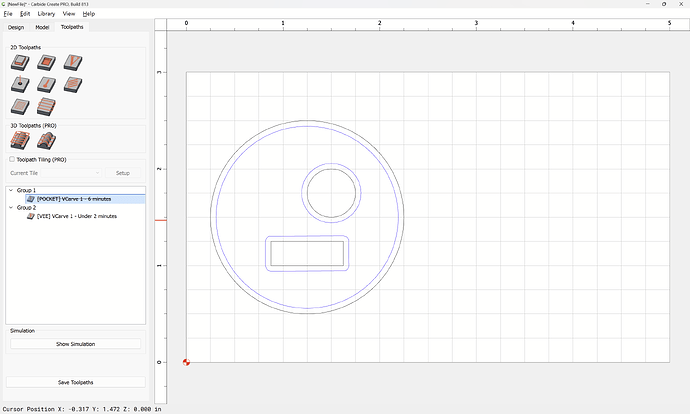

and two toolpaths when I disable that:

Upload your file and a screengrab showing no second toolpath?

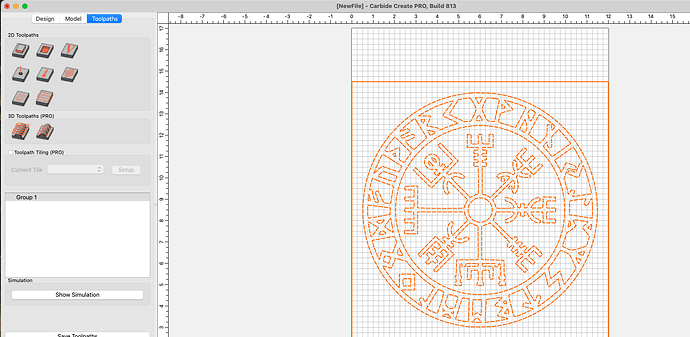

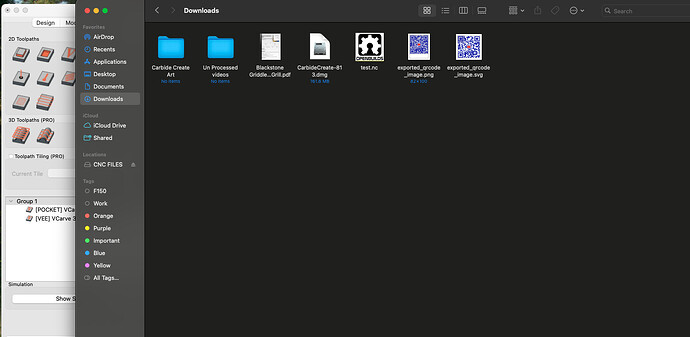

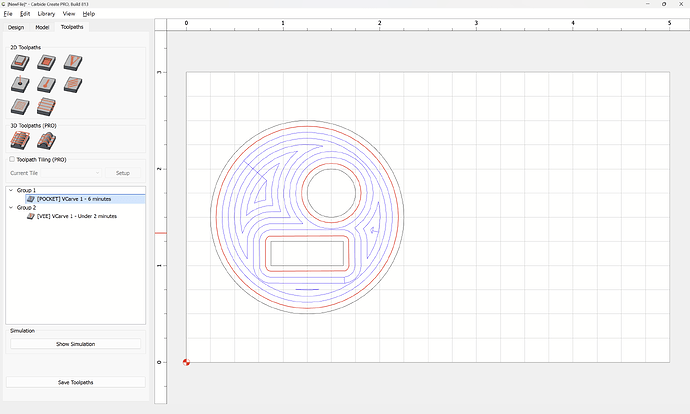

I threw something together quickly to show its no longer splitting the files into separates. Or Im missing something Is probably what it is.

I tried uploading the code but it to large. heres a link

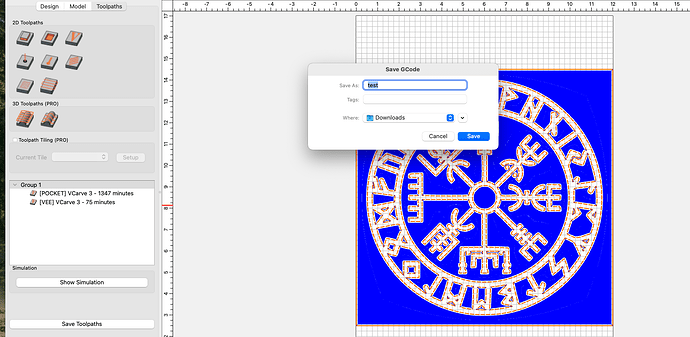

In order to get two separate G-code files, you will probably want to move the separated toolpaths into two separate groups:

and then disable one or the other before writing out G-code:

Ya that seemed to work But I swear when I first downloaded V8 Beta it automatically did the file split into separates. In Fact I know it did. because I was like VERY COOL. But if I have to do it this way then so be it Thanks for the help

It did not. We’ve never generated multiple files automatically.

Ok Then if was a fluke in my putter or else Im going craze LOL But anyways thanks for the help its working again

Updated the unofficial:

to reflect the current state of v8 — let me know if anything was missed, or which needs to be updated/corrected.

It has been tested and documented that Rest Machining doesn’t really use the Previous Diameter but the current diameter, at least in cases where one sizes down by half.

The workaround is simple unless, as I do, you use tiny bits and run up against an imposed minimum of 0.250 mm. I frequently follow a 0.254 mm bit with 0.178 mm bit which means the smaller bit traces the entire path of the larger bit.

Please remove this restriction or set the minimum to 0.15 mm or 0.10 mm.

I’ve noticed that the plunge rates look fast on contours during the second pass. The first pass looks OK, then subsequent passes looked fast and are flexing the bed and chattering sometimes.

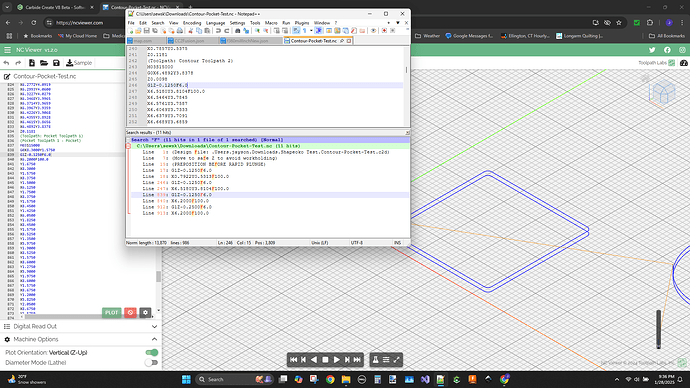

As a test, I wrote simple contour toolpaths and exported the G code from Carbide Motion. When it cuts the pocket, it specifies the feed rate for each plunge. However, on the contour toolpath it only specified the feedrate at the beginning for the initial Z plunge and then subsequent plunges did not specify the feed rate for the Z.

I’m a programmer, but not being familiar with g-code, I asked ChatGPT about this and it is telling me “Feed rates are modal,’ meaning they stay in effect until changed for the plane they were specified. However, it is good practice to specify the feed rate. If another F command was introduced earlier (e.g., for X/Y movements), the Z-axis might default to that feed rate if not explicitly redefined.”

I believe this is why I’m seeing rapid plunges on subsequent contour passes. I definitely didn’t expect my bit to plunge into material at 100IPM.

I’m using the free version of Carbide Create, build 778 and v8 beta, and Carbide Motion build 640.

I’m on an Apple M2 Sonoma Version 14.6.1

My cnc machine is a Shapeoko 5 Pro 4x4 and the QR code sticker says Nov 2023, Rev 3.

The files attached were created with v8 beta and Carbide Motion build 640.

Contour-Pocket-Test.c2d (44 KB)

Contour-Pocket-Test.nc (13.5 KB)

Here’s a video showing the paths being cut on a scrap of MDF. Notice the plunges on the second contour passes.

Z-axis speed is limited by the controller setting. None of the current Z-axis hardware is capable of moving 100IPM as far as I know. I have my Z-plus set to 1200mm/min(47.2in/min) which is higher than default settings.

Well, I don’t know how fast it is moving, but it’s definitely not the 6IPM I set as the plunge rate for the contours in the example file.

Yeah, that’s cause the stepper motor can’t move the Z-axis that fast & it’s limited by the controller max speed setting for the axis. G-code/project file speed settings only apply up to the max speed settings in the controller. The controller axis max speeds basically defines how fast the steppers can move the spindle/router around plus cutting tool with very little resistance & not lose positional steps/accuracy.

If you try to cut at those speeds & there is too much force against the cutting tool(dependent on material being machined, tool profile, spindle RPM, toolpath DOC/stepover/speed/acceleration), then the steppers don’t actually move with each pulse sent by the controller & the machine is no longer positionally accurate. The error builds up until the operator notices that the cutting path does not match the programmed path at which point the whole project piece may or may not be ruined. Curse words ensue. Troubleshooting protocols begin. Knowledge & learning is advanced.

After reviewing your video, I see what you mean. The initial plunge certainly seems correct but the 2nd plunge looks to be at max Z speed limited only by the controller setting & not the Plunge rate defined by the tool setup. Certainly possible this could be a bug as CCv8 is still in Beta.

I usually use the ramp feature since it became part of the program for which I’ve never noticed it to not slow down properly.

Running CCPro 812

Problem doing importation on another V8 file.

Rest toolpaths are still not being imported.

Hi

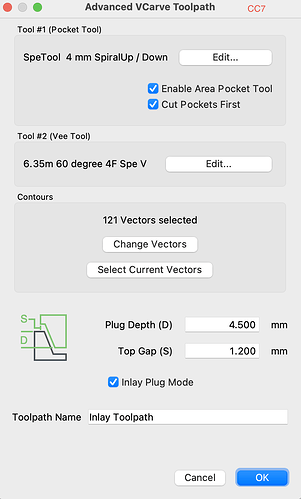

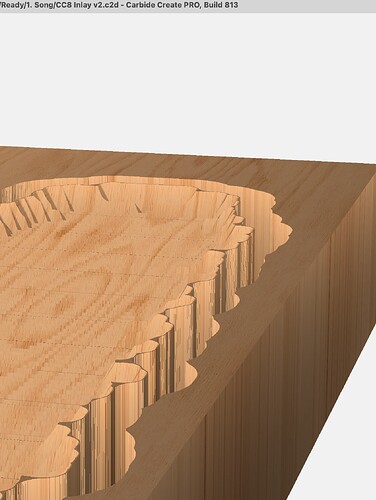

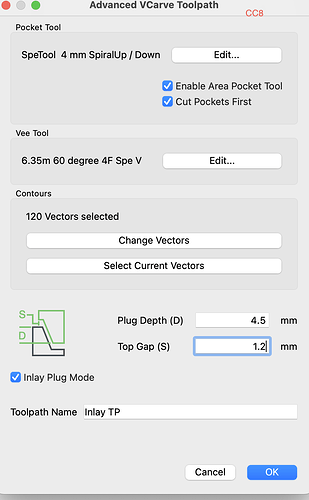

Running CCPro 813. I am using advanced v carve for an inlay. If I use CCPro 7 the inlay simulates correctly. See screen shots. But then using the same settings on CC8 the inlay doesn’t work. The screen shots show it better than I can explain. User error or bug? I have written CC7 or CC8 on the settings screen shot

Thanks

Josh