Off topic, but is that the Keweenaw Peninsula?

Yooper might be a clue.

Yes, it is. I live about 45 miles-ish from the tip of the Keweenaw.

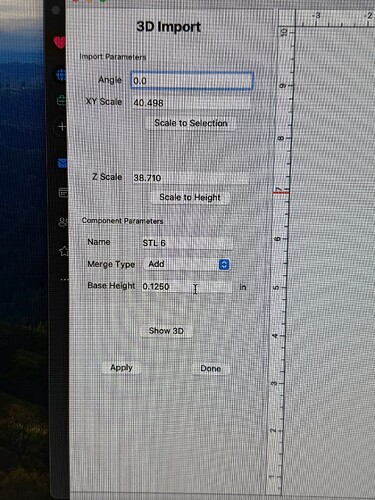

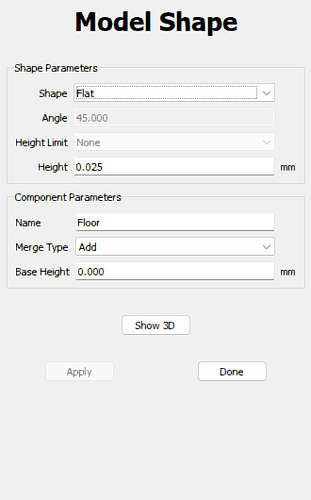

The first height map I made I have a 0.125" base. It took a while because it cleared a large area of the board. The pic I have included shows the project after I was done with it and cut the base smaller. Is this what you mean by the base? If not, how would I go about setting this? I also included a pic of the 3D import parameters for the Keweenaw carve I am trying to do.

No, I do not mean the the Base Height parameter when setting up a 3D component.

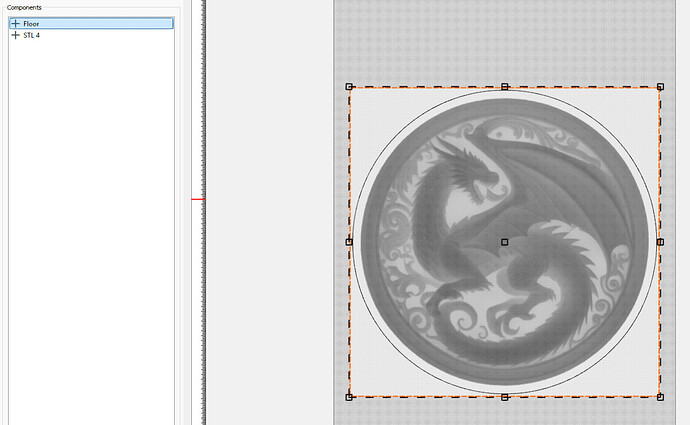

I probably should have been a little more descriptive. In your prior post you show a screenshot of the 3D Toolpath Simulation & it shows that it is cutting right through the stock - usually you don’t want to see that with 3D Toolpaths as it can result in the toolpath dropping way DOWN & into your nicely flattened spoil board. To prevent this, you create an offset outline or circle or rectangle/square signficantly larger than your 3D model & create a Flat 3D component from it. This is your floor. It doesn’t have to be very thick - 0.001" will do. Then you build your 3D model component on top of that. Thusly, when creating the 3D ToolPaths for the 3D carve, it won’t calculate to go below the Floor.

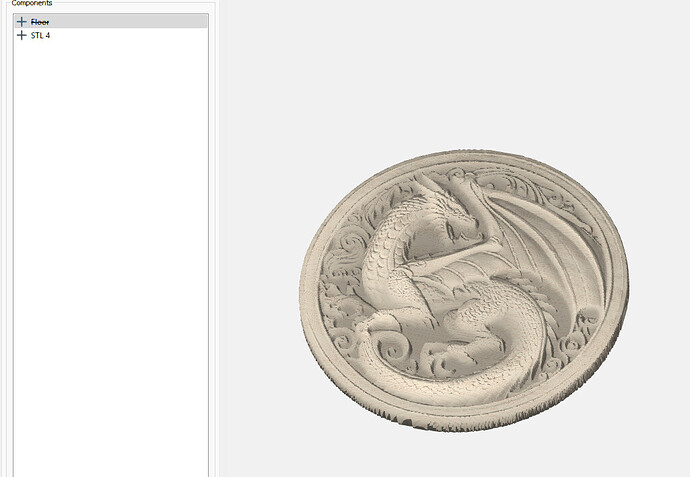

Without Floor in the Modeling Tab:

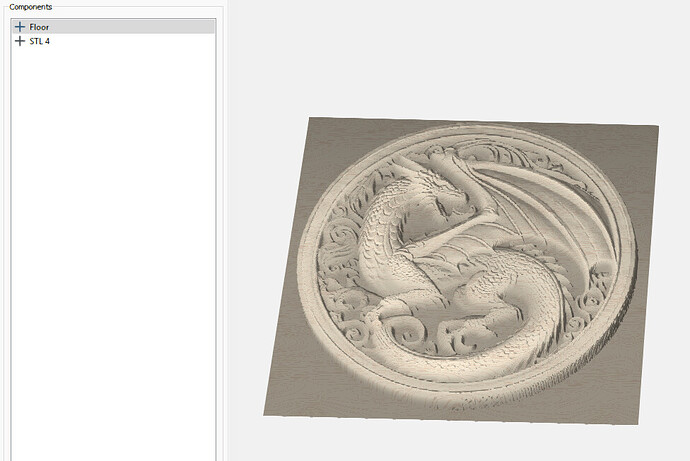

And then in the ToolPaths Simulation:

With Floor:

Anyway, I hope that helps you out.

This helps a lot. Thank you for the assist!!

I think we got the “Sergey Bug” fixed in 811: Carbide Create Beta Downloads

- (Fix) Pocket toolpath for V-carve now shows the correct tool in the toolpath list.

- (Fix) Advanced V-carve no longer generates a tool change for the V cutter in the pocket toolpath.

812, a bug fix release, is posted to Carbide Create Beta Downloads

- (FIX) Crash if an invalid scale is entered for the background image.

- (FIX) Crash if the ramp angle is zero.

- (FIX) User-reported crash in texture toolpath.

- (FIX) Naming errors in split V-carve toolpaths.

- (FIX) Crash when duplicating a split V-carve toolpath.

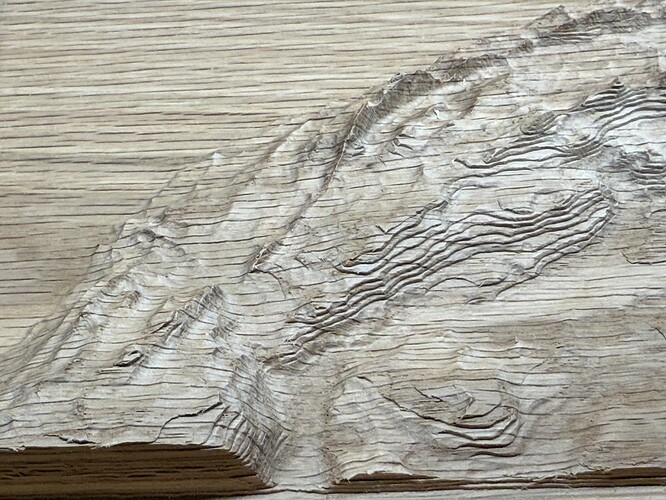

I have completed a height map carve. For the life of me I do not understand why the finishing carve, which was initially done with 1/16" bit is leaving sections from the rough cut 1/4" end mill untouched. I even went back with a 1/8 round which helped some but still left a ton of ridges. What am I doing wrong?

KewPen4.c2d (44 KB)

How are you managing the tool change?

Unfortunately, your .c2d file doesn’t seem compleat — is it actually only 44KB? Try zipping before uploading?

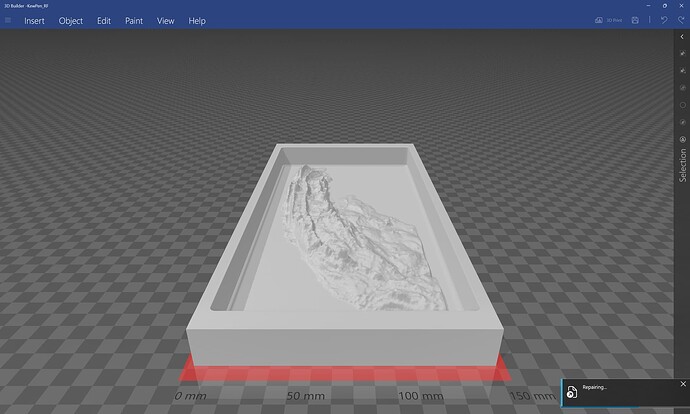

When I made a 3D preview of the G-code files you posted and converted them into an STL they seem fine:

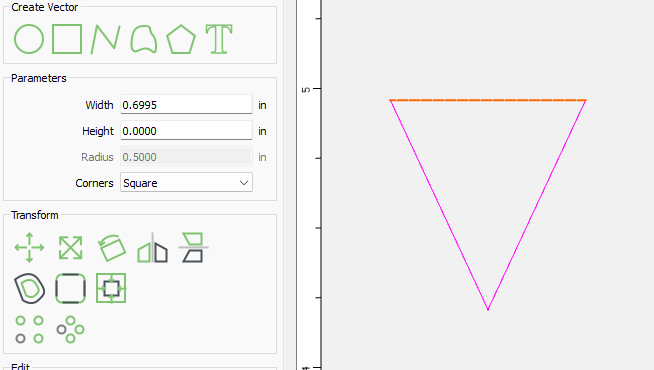

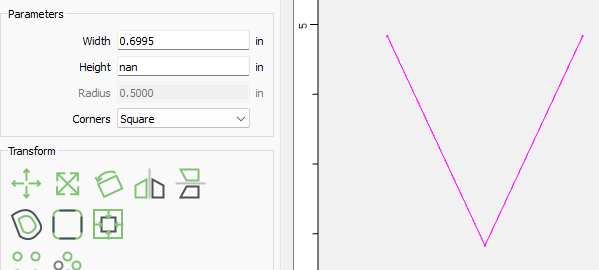

V812 I have 2 angled lines I drew as a cross section & want to make a rectangle the same width.

I used to draw in a rectangle using the CTRL key go corner to corner & pick the 2 top nodes.

Rectangle is the width by 0.0. I would then change the 0.0 to the height I wanted, tab or enter & it would update. Now it registers nan rather than replacing the 0.0

I looked at the file and for some reason it blank. I am not sure what happened. When I save the g-code files and save them individually on a SD card. I have a Foxalien Masuter Pro. When the rough in is complete I will do a tool change. Once the tool change is complete I will move the router back to a position that I have marked as the starting point. I will manually move the z axis to the proper height then re-zero the axis and start the next part of the carve. I am sure this is not the best way to do this but seems to have worked pretty well for me. At least appears to be:)

If the G-code previews correctly and the file doesn’t cut to match, then the problem is either feeds and speeds, a mistake made in loading tooling, or an electro-mechanical issue with the machine.

Does it matter if the carve path is set to zero or 90 deg like I did this carve? I would assume not but not sure.

Angle of a 3D cut will interact with wood grain direction, and for a Finishing toolpath the directionality of tooling marks, but otherwise shouldn’t affect how a file cuts.

OK. I was going for the cleaner finish on this. A different height map I did had the same issue with the face of the hills/cliffs not getting touched in the finish carving. I will have to see if I can find videos online for this type of carve. It is frustrating because of the time it takes to complete the carving and it not doing what I want it to.

Or to export as either DXF or SVG would be great

There is an option to export as an SVG in the File menu already.

The Offset vector function no longer shows a preview of your desired number like it should. You have to commit the change before you can see it. This should be fixed and work as it did in v6 and v7

I cannot reproduce this. Both in v7 and v8, I don’t see any “preview” - I only see the offset when I press “APPLY”. As far as I can see, the behavior is the same between the versions (777 vs. 812)…

- Gary