If you go back to 622, does it work again?

Yes, installs normal and works just fine.

Can you try the beta and then copy the info from the Settings->Debug window when you get a lockup?

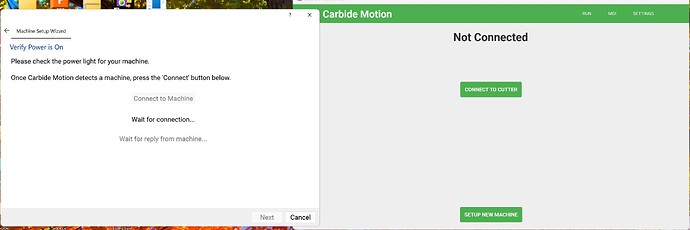

Motion wont let me click on settings while the setup wizard is open, wizard just keeps going from connect to machine, to waiting for connection and back to connect to machine

The newest RPi version (630) will not let me move to a negative coordinate via the MDI interface. I use this when I surface a piece when the first surfacing pass doesn’t take off quite enough. I will move the Z axis to a negative value (typically -0.005 inches) and run the surfacing again. I cannot seem to be able to do this now. Any suggestions?

While I’m at it, I’ve also noticed that using the rapid position to move to the SW corner instead moves to the center of the workpiece.

Are you sure you setup CM for the correct size of machine? I recall when I first tried CM 6.xx & I hadn’t set the correct machine size in the wizard which caused some weird issue.

I’ve never tried setting the Z-axis thru the MDI, always just jogged the Z-axis a little bit more down to reset the zero point to surface a bit more off.

Maybe you need to use machine coordinates vs. the relative offset coordinates?

Yes, I did make sure CM was set up for the correct machine. I actually installed it fresh on a new RPi and it required me to tell it which machine I had (Nomad 3). Prior to the latest version, I was able to use the MDI to move the Z to the point I wanted. The jogging functions are hit and miss when doing very small increments, but I’ll have to give it a try the next time I have the machine on.

It appears that 6.31 won’t let you rapid to Z or Z+6 when you have disabled the BitSetter.

Attempting to rapid in that direction displays “The current tool has not been measured. Would you like to measure and continue?”. ‘Yes’ is wrong because the BitSetter is disabled and and clicking ‘No’ exits the modal and returns to the previous screen without action. I was able to work around this by manually jogging to Z=0, but it seems as if the logic isn’t taking into account the flag that disables the BitSetter.

Downloaded and tried the beta today. So far so good on all the basics. Noticed what seems like faster bit measurement. After hitting bitsetter the first time, it slows down, but not nearly as much as it used to as it does the second measurement. And the not measuring tool until setting Z is pretty nice. Don’t like the returning to the point it was at after though. My last step before running a job is setting Z. So when I hit Z, it goes over and hits the bitsetter, and instead of going to the bit changing spot, it goes all the way back to zero. Then when I start the job, it goes all the way back again for tool change. Might be better that after you zero, and it does the bitsetter, it just goes to the tool change location. Just my $.02

I’ve finally run the beta through it’s paces enough to have some input, and I’ve just gotta say that not only is the faster workflow wonderful, but the faster probing for both BitSetter and BitZero is an absolute godsend.

Now to add in an option to automatically pause the program after using BitSetter so those of us with Sweepy Pros can get the bottom piece on after a bit change… ![]()

If using a Sweepy Pro, you’d want a pause every time there’s a BitSetter check? Presumably, this pause would be best handled when the spindle is retracted to the top of travel?

With my Pro XXL, I have the sweepy pro height set where it doesn’t interfere with the bitsetter, basically the bristles don’t extend beyond the end of the cutting bit.

That works w/ a Pro (or 4 or 3) since the BitSetter is out front and low relative to the top of the MDF filler strips — but it’s often not workable for an SO5 Pro or HDM.

On the SO5 after the endmill has been measured there’s a brief pause after it’s raised to the top of the Z and slid over a bit to the position where it initiates the tool change. A second or two later the spindle kicks on, and the job continues.

As it stands, if you’re using the C3D spindle and have the spindle disabled via the button on the VFD or if you’re using the Sweepy Pro that doesn’t clear the BitSetter the workflow requires you to hit the feed hold button on the pendant during that few second pause, put the bottom half of the Sweepy Pro in place, enable the spindle (which may or may not spin up depending on how fast you were on the pendant), then continue the program in CM.

An option to automatically pause after measuring with the BitSetter would eliminate the hectic few seconds of hitting the feed hold button manually at the correct time. I’d love to see it pause at that point, then once continued in CM it would turn on the spindle and continue on it’s merry way.

@SLCJedi anything else to add here? I know I’ve seen you mention this as well.

This would definitely be helpful.

I agree. I know I’ve mentioned it a while back, and there’s been a lot for C3D developers to take in since. But a pause (opinional) after the BitSetter routine to position the Sweepy Pro would be awesome. I love the Sweepy Pro on my S5Pro and that’s my singular suggestion to improve its use.

We just posted a new build to Carbide Motion Beta Downloads

- New - New error popup to give better context around a problem.

- Fix - Rapid to Current Z function failed without BitSetter.

Still not able to get the beta to connect to my machine, anything else I can try?

The only thing that comes to mind is to restart the computer and run only the beta build to make sure the port isn’t locked up by another program.

Tried above and still the same, wizard is also running extremely slow for some reason.