This is known as “rest” machining.

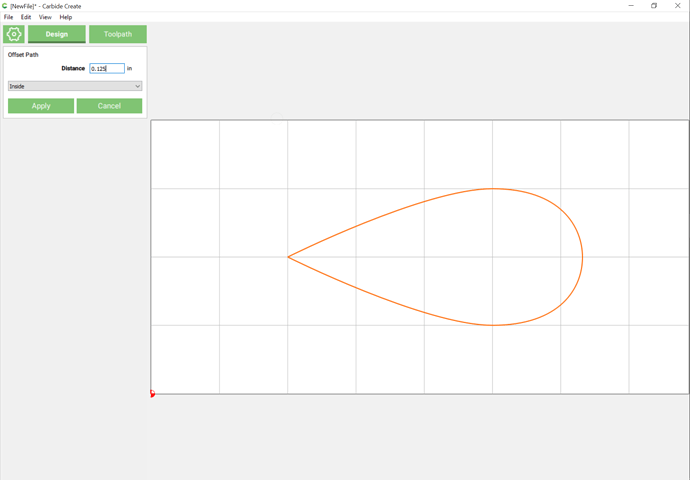

At this time, Carbide Create does not support this feature — one can do it manually by insetting by the endmill diameter, then outsetting by the diameter:

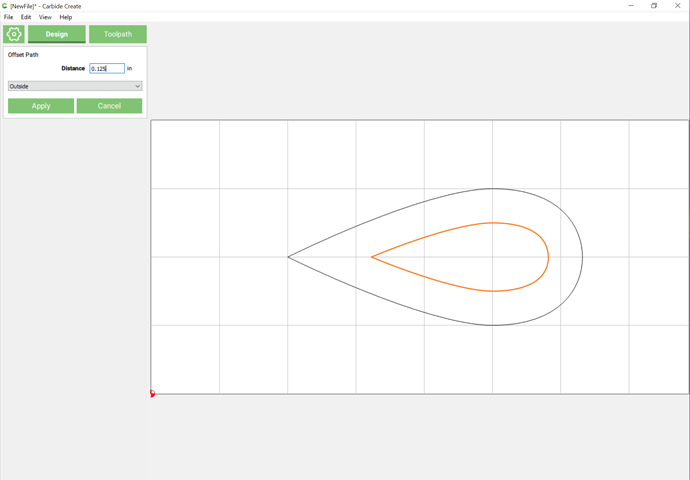

resulting in:

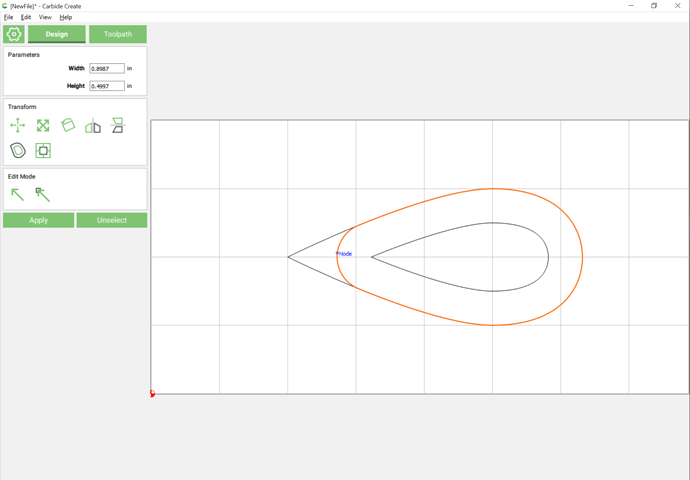

resulting in:

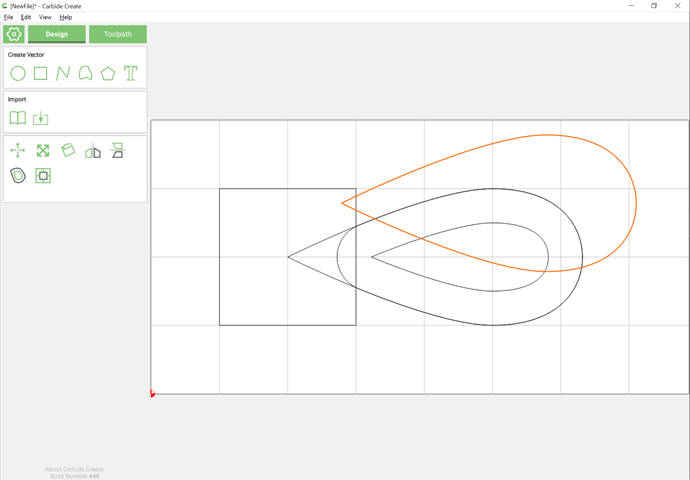

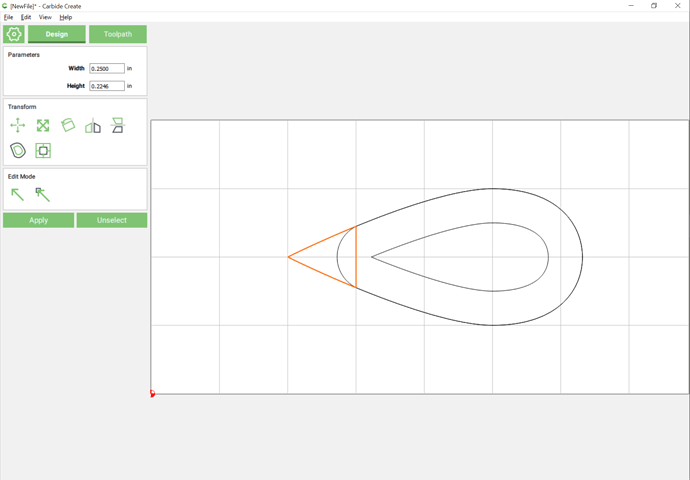

Draw in geometry which defines the area you wish to work with and duplicate the original:

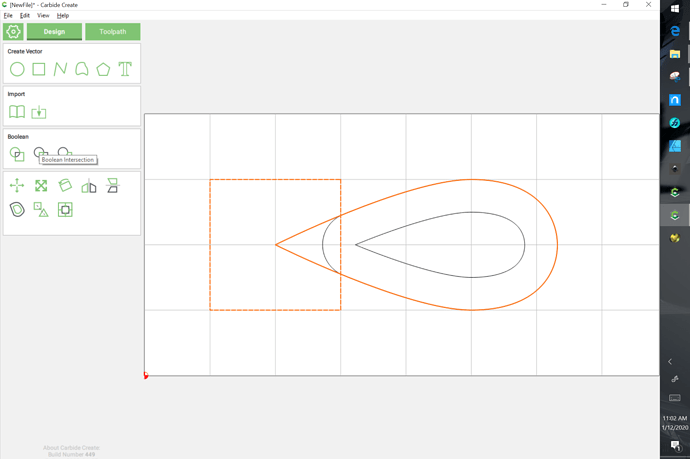

drag the original back into alignment and select it and the drawn in geometry and do a Boolean intersection:

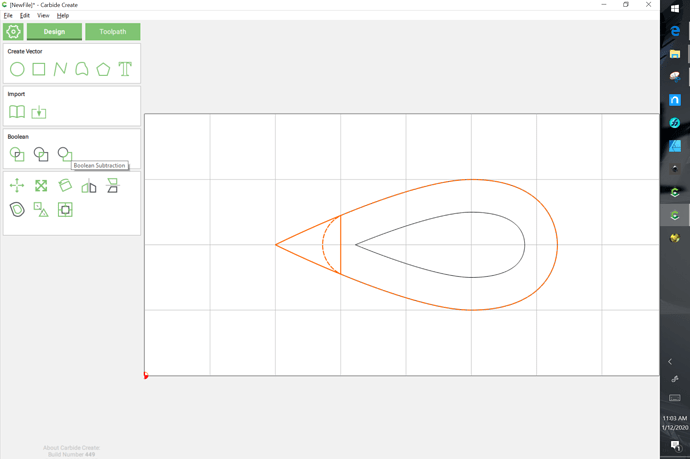

then select the offset geometry as the key object and Boolean subtract it from the region you are interested in:

EDIT: You would further want to offset to the outside by the radius (or diameter?) of the tool in question, then do a Boolean intersection w/ a copy of the original geometry.

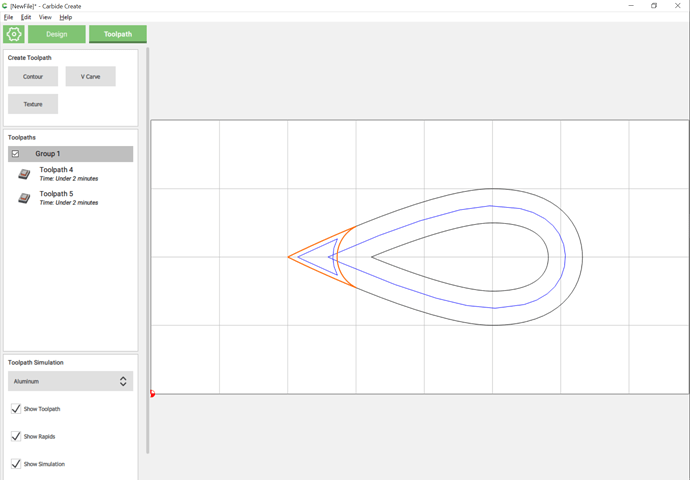

resulting in an area one can separately assign toolpaths to:

One can get even better detailing though by using a V carve for detailing instead.