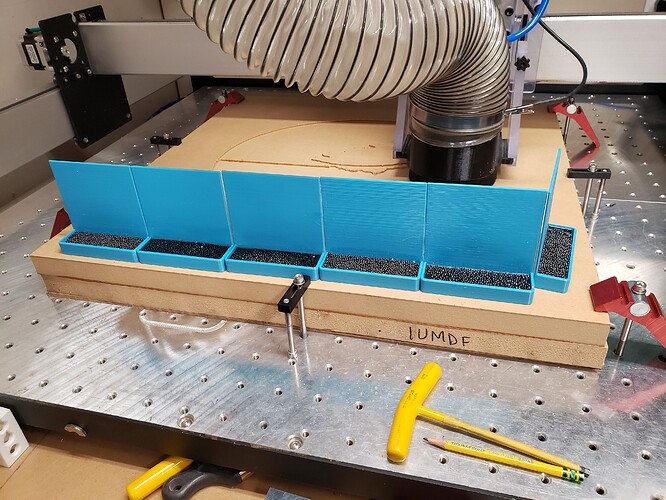

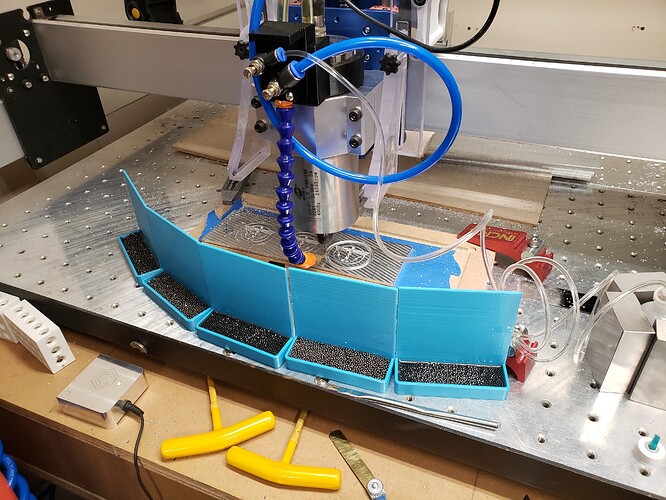

So, I have cut 1/4" 6061-T651 plate aluminum with a 30deg V-bit and a cheap 1/8" single flute cutter, and it went okay. No big issues to speak of. I used 99% IPA for lubricant and blew away the chips with low pressure air. I have a misting cooler / air blast that I bought on recommendation from someone here - I forgot who, sorry.

But I am now trying to cut some simple clamps out of some 1/2" 6061-T651 plate I bought. No, I don’t need the clamps, but they are simple and I can learn how to cut aluminum on a simple part, and if they work - I have more clamps. On to the problem. I used a Kodiak 1/4" 2 flute AlTiN coated bit to cut the aluminum, and it was quite a different experience than when I cut with the 1/8" bit. My Feeds and speeds were:

Feed: 50ipm

Plunge: 30ipm

DOC: 0.05" for one 0.01" for second

Speed: 24K RPM

After these two failures using that bit, I went back and actually looked up the feeds and speeds for aluminum. Yes, ladies and gentlemen, I am that guy who doesn’t actually look up info and learn from other peoples’ mistakes. So, now I know that I should definitely slow down my plunge (it did seem a tad bit fast) and slow down the feed a bit, I can finally get to my question:

Is the $40 single flute Carbide (or Amana) bit worth it? I mean, the crappy $15 two flute bit was terrible, and when you see the pics, I think you’ll agree, and the cheap (About $1/ea)1 flute 1/8" bits I used worked great, so - Who has used a crappy bit and then switched to one of the “made for aluminum” single flute bits and thought it was totally worth the cost. Because if it is worth it, I’ll buy it, but if it is like “Yeah, it was better, but. . .” then maybe I’ll work on other things.

EDIT: The reason for the “Snap” was I tried one more bit, but it was an “extra long” bit and it chattered really bad - like a lot more than the stub bit I used the first time, and then it snapped. Something I was not expecting. And it also damaged my collet - something I did not think possible. So, now I have a new 1/4" ER-11 collet on order.

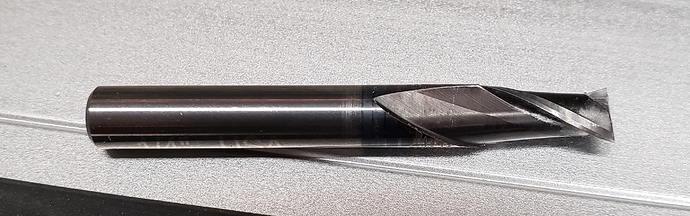

On to the horror show. Here’s the bit I used:

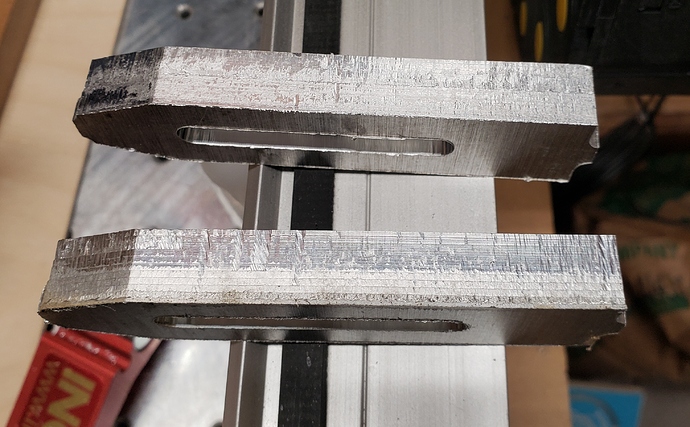

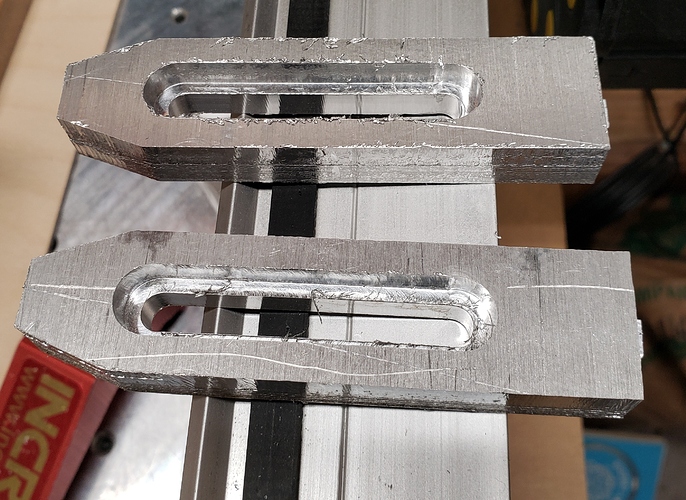

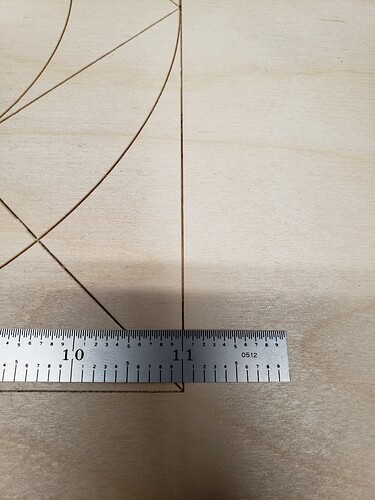

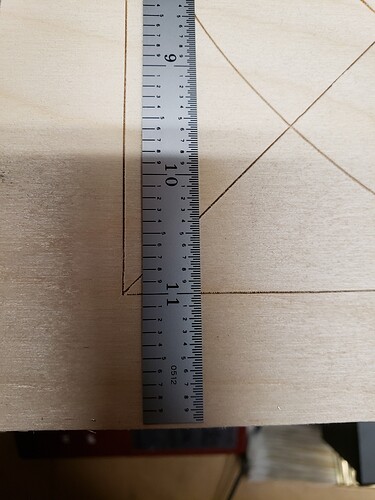

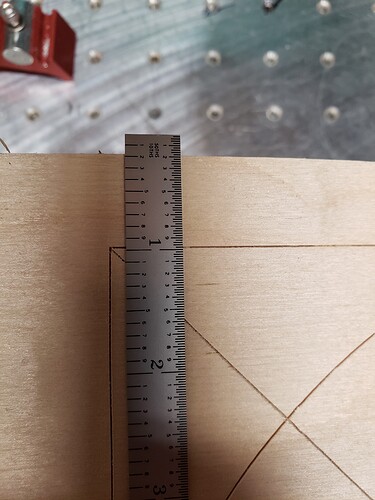

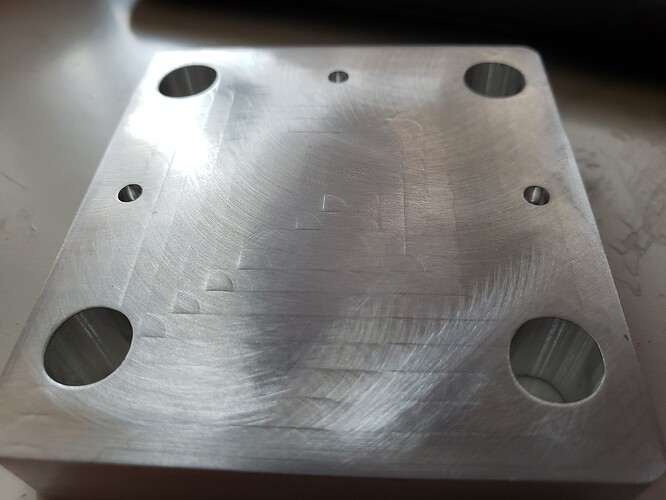

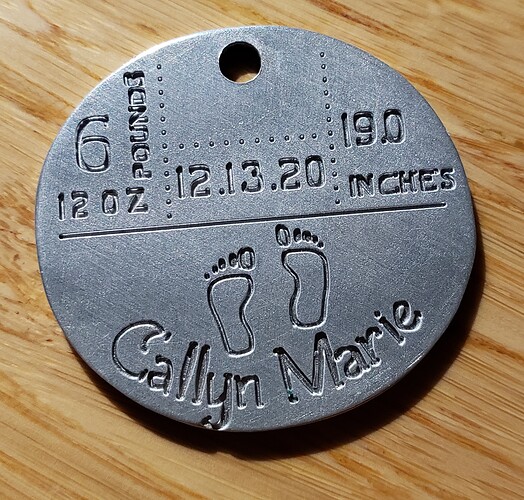

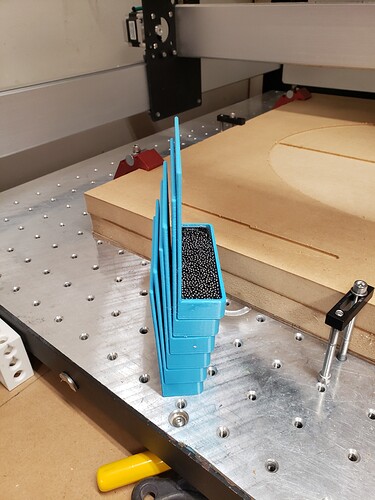

Here’s the carnage: One is cut at 0.050" DOC and one at 0.010" DOC.

On another note, after using my disc sander with 60 (or 80) grit (I can’t remember) and putting them in a vibratory cleaner with some abrasive impregnated plastic pyramids for polishing aluminum, they have a nice matte finish.

They still look like crap because I learned what not to do regarding the cutting and the sanding job was just a quick clean-up to get rid of the ugliness. I am still going to clean them up a bit more before I throw them back into the vibratory cleaner to go at it again. If the part is sanded to120-220 it should look nice, but where the aggressive sanding disc striations were missed with the 120 grit belt sander, it still looks ugly.