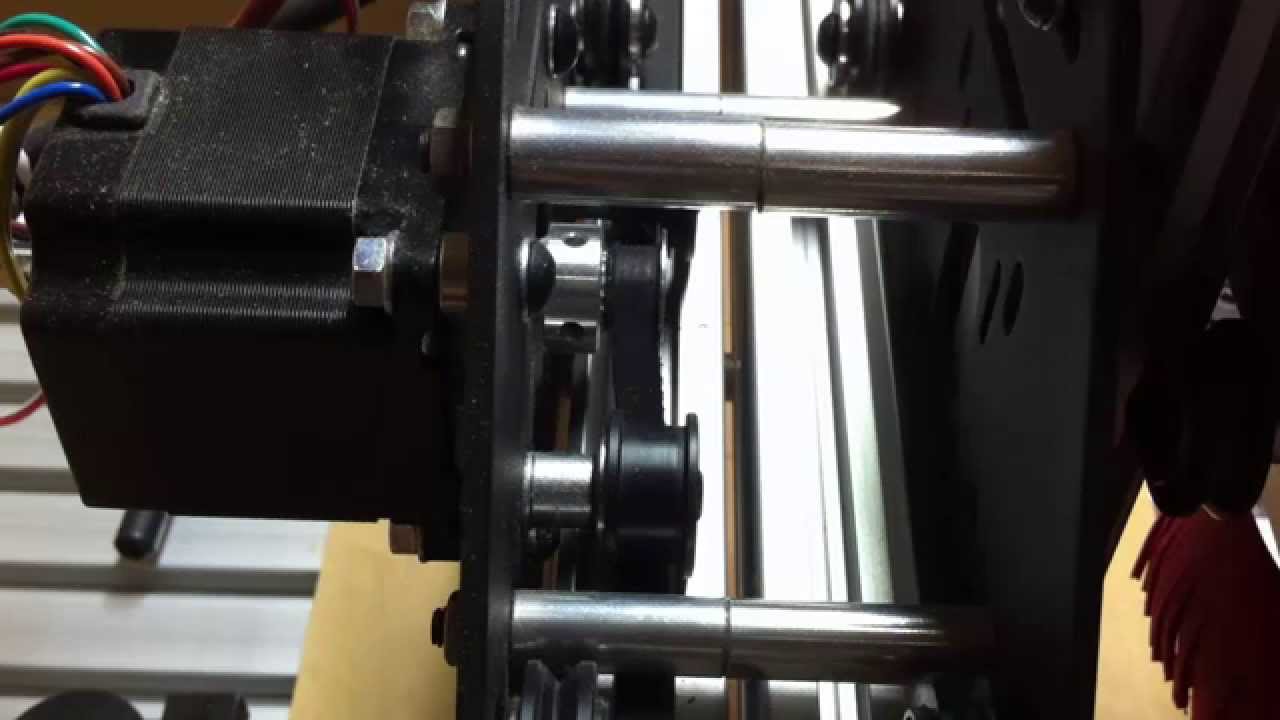

Just curious if there are any recommendations for cleaning/ oiling and just regular CNC upkeep for my Shapeoko.

There is of course:

http://docs.carbide3d.com/general-faq/machine-operating-checklist/

EDIT: and now:

and for Nomads:

https://docs.carbide3d.com/nomad-faq/what-oil-should-i-use-to-lubricate-the-linear-bearings/

and for a Z-Plus, HDZ, or Nomad 3 or Pro see:

https://docs.carbide3d.com/nomad-faq/what-oil-should-i-use-to-lubricate-the-linear-bearings/

c.f.,

The Delrin V-wheels can be cleaned at need with a cotton swab, and a microfiber cloth works well for the Aluminum V rails. The neoprene (rubber) belts may be cleaned with a suitable cleaning product if need be.

While for the SO2, this is still a good overview:

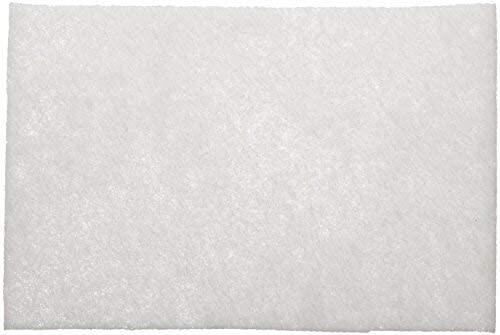

On v-wheels I use a stiff nylon brush while pushing things around to get 360 access. On the rails I use the 3M fine/extra fine finishing pads. They are the nonwoven pads. They are white and will not scratch your rails. Mineral spirits selp with stubborn stuck on crusties.

Would you happen to have a part number for the pads, @gdon_2003, please?

All I can find here is black or Scotch-Brite pads.

Thank you.

It is the white ones.

3m 7445

Thank you. Ordered from Amazon.co.uk - and will be delivered from the USA.

Awesome!

Keeping the rails and v-wheels clean has been my primary maintenance activity over the last year. Toothbrushes are great for cleaning caked-on sawdust from v-wheels. I’ve been considering designing a fixture to permanently hold a toothbrush against each v-wheel, but I haven’t made my peace with the jankiness factor.

DIY.Engineering sells dust covers for the SO3’s v-wheels (here), but they’ve been out of stock every time I’ve looked.

Hi Jeff, all fantastic questions. Janky is sort of like kludgy, and a kludge is what I think you Brits call a bodge. Jankiness (units of Janks) can be directly converted to sketch factor, where sketch factor is log base 10 of Janks. Typical values for jankiness range from 10^1 to 10^11 (sketch factor 1 to 11).

Jankiness, or sketch factor for ease of units, is measured according to documented statistical tables describing the risk to persons and property associated with some piece of workmanship. A sketch factor of 11 means someone’s definitely going to die, while a sketch factor of 3-4 is a group of tradesmen looking at their crude patch job and saying, “It’ll do.” Balancing a ladder on a forklift is a widely accepted reference point coming in at 8.9 — substantial risk to life and limb. Calling something a sketch factor of 1.5 or below (<30 Janks) is just fishing for compliments on a pretty decent job.

The actual jankiness statistical tables are closely guarded by the international standards organization, but most engineers, tradesmen, and amateur craftsmen develop an accurate intuitive feel for it over time.

Hope that helps clear things up!

Travis is mostly correct, though I think he’s definitely breached his non-disclosure agreement. I recommend he reread section 17, part 2, paragraph b thoroughly. Particularly the sentence pertaining to limb removal.

In 1918 when I was Professor of All Science at the New York University of Very Clever Things, we started work on something we called a Jank-o-scope - a device we hoped at the time would be able to accurately measure Jankiness with a precision of 0.1 of a sketch factor (+/- 5,000). Despite some initial success, the device’s innate tendency to melt prior to exploding forced us to retire the project. This is something I’ve always regretted.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.