Whilst waiting for our official maintenance guide for linear rail and carriages I thought it might be prudent to post a draft here.

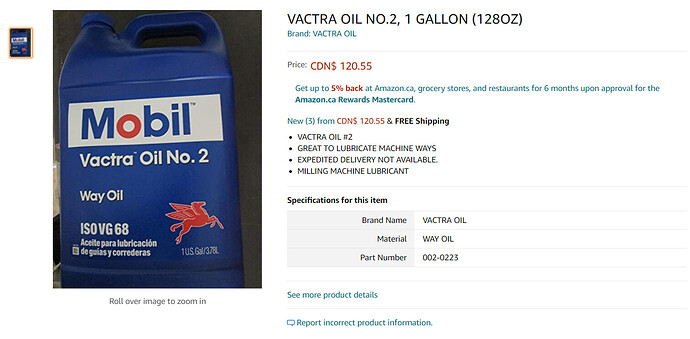

At present we don’t offer oil for our carriages or linear rails, however it can be bought cheaply from Amazon, ebay and in most cases local machinists stores.

We only recommend using Mobile vactra No 2 oil on linear rails, ball screw and carriages. It should not be used on any other parts of the machine. Follow the safety guides provided with the oil. Wear gloves/glasses.

Linear Guide and Carriage Maintenance

Our linear guides are rated for tens of thousands of hours of use and should not wear out. To keep them in good condition we recommend the following:

- Keep them dust free, wipe them down with a clean dry lint free cloth after each use.

- Never use a water based products on them

- The rails can be wiped down with a clean rag/cloth with a small amount of Mobil Vactra No 2 oil - be sure to clean off any excess.

Some people are surprised that the carriages will occasionally leak a small amount of oil. Without going into too much detail on how the carriages work it’s notable these are full of moving bearings and not V wheels. Internally there are a series of ball bearings which rotate and move around in a channel. All our carriages are double rubber sealed to keep these lubricated and to keep dust out.

Depending on use we recommend injecting oil into the carriages, whilst not required it will prolong the life of the carriages.

To do this it’s usually easier to remove the axis from a machine. It can be done on the machine but access to the lower carriages can be difficult.

If you carry out this procedure whilst the axis is on the machine raise the Z to the top of travel and ensure a disposable cloth is placed under the axis.

If you remove the axis place it flat on it’s back. Remove the small M4 grub screw central to each carriage.

Fill a large bore plastic needle syringe (10ml), press this firmly into the hole and gently squeeze between 1-2mm of oil into the carriage. Replace the M4 Screw after.

DO NOT REMOVE THE CARRIAGES FROM THE RAILS - This will cause the ball bearings which are under load to fall out. Note if you remove the screws holding the carriage onto the lead nut, it’s likely the carriage will slide off by accident.

Ball Screw Maintenance

Ensure carriage fitted to the machine - with the machine on, homes and brought to the front for easy access.

Clean the ball screw any dust/debris after each use.

To lubricate, set the axis at the lowest point and using the same syringe method gently squeeze a small amount of oil onto the ball screw.

Once this has been done move the axis up and down a number of times to spread the oil onto the ball screw.

Lead nut Maintenance

The Z plus uses a lead screw. Not a ball screw - do not apply oil to the lead screw.

Lead screw maintenance is very straight forward, these should be kept clean, and dry. We recommend cleaning any dust or debris off the lead screw and nut where possible. Ideally after each use of the machine.

How often should this be done?

This will vary on use but every 6 months or so will keep everything in tip top order. Everything is rubber sealed and as long as it’s kept dust free and clean could keep going for years without needing a oiling.

Hopefully this helps - and we will shortly have an official guide for print/down load. Any questions shoot them off here.