This recent post got me thinking that it could be interesting if we shared our CNC workflow/habits/tips here, since this a very general topic with lots of opportunities to mess up something at each step, and therefore lots of opportunities to have a few mitigations in place to catch the most common errors.

Mine is hobbyist/amateur-style, I don’t actually have a written checklist (maybe I should), but it goes something like this:

- once a project idea has emerged, I rummage through my pile of material. More often than not, already at this stage I can be sidetracked because I stumble upon that specific piece of material I had set aside to use “someday”.

- then I decide which CAD tool I will be using. Typically, that would be:

- Carbide Create for 2D parts, 3D relief carving (ever since I had a taste of CC Pro + @fenrus STL2PNG online tool), and simple V carve jobs.

- VCarve for complex V carve jobs and 2-sided jobs (just because the “top”/“bottom” view feature is quite helpful in that case)

- Fusion360 for parts that involve 3D modelling, and for parts that I know will benefit from adaptive clearing toolpaths (e.g. cutting metal…).

- If dimensional accuracy is going to be a concern, I anticipate that in the CAD either by using offset geometry (in CC or VCarve), or by using “stock to leave” in Fusion360.

- I determine feeds and speeds based on my chipload religion, using a spreadsheet (my basic one or the great one from @gmack) or simply scribbling “FR = target chipload x nbflute x RPM” on a piece of paper, and when in doubt I’ll go and double-check what CC database says, what Winston says in his MaterialMonday videos, and if I am in a really specific case I’ll go search for posts on the forum (like, V-carving in metal ? let’s go check search for @Vince.Fab posts on that)

- I’ll generate the G-code depending on which CAD software I used: the built-in proc in CC, or @neilferreri’s excellent posts for Vcarve and Fusion.

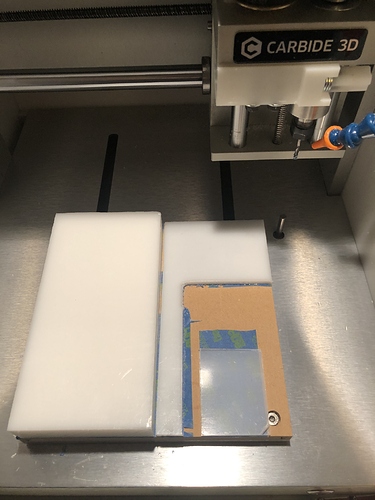

- I’ll think for about 0.01 seconds about which workholding method to use, and choose tape&glue.

- I’ll take a look at the surface of my wasteboard and go “yeah, that should do, I’ll resurface it some other time”.

- I will try to install the stock parallel to the machine axes: usually using some marks in the wasteboard from a previous overcut, but I should probably get in the habit of using corner squares

- when (or before) I load a G-code file, I like to double-check visually whether the cut looks as expected: I wish CM had a 3D preview pane, when I use CM I’ll go and check my G-code using an online G-code viewer (for some reason I keep going to this one), it takes all of 5 seconds and prevents the most likely error: stupid me selecting the wrong version of a file. I will usually look at the general shape of the toolpaths, the extent in Z direction/max depth of cut, AND where I set the Zero.

- for zeroing, to this day I still use two methods:

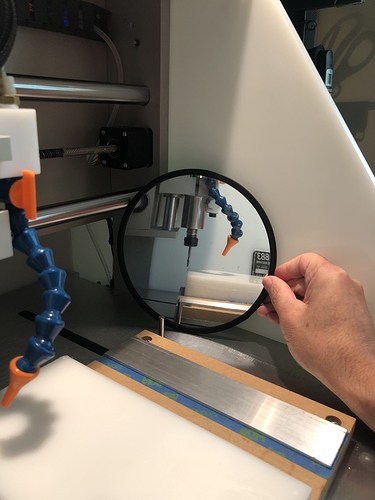

- good ol’ paper touch off, when only accurate Z really matters, and I can eyeball X/Y. It’s accurate enough for many of my usecases. I hear people using feeler gauges, maybe I’ll try that instead of paper, someday.

- probing: whenever I need accurate XYZ zeroing (typically: metal job referenced to top left corner). I also like to use a probe when using V-bits, because it’s easy to be inaccurate with those bits using the paper method.

- for tool changes, I like my BitSetter a lot, so I’ll use that whenever I can, either from CM, or from CNCjs. I try and switch off the router power while changing the tool (since I don’t want to trust that single PWM wire to not turn the spindle back on at the worst moment, should a bug or hardware failure occur).

- since I have a spindle, I don’t have to worry about turning the router on and off, the G-code takes care of that for me. If only that feature were available to router owners…

- After I have zeroed / bitset, I’ll close the front door of my enclosure, then turn on the vacshop (OR compressed air jet for metal work) from my poorly made control panel.

- And then hit “run”, with my hand near the E-stop button.

- I’ll stay at the machine side, maybe doing something else on the computer if it’s going to be a long job, but always, always within hearing distance. And I have a fire extinguisher in the garage, should things go south in a very very bad way.

- then switch off power on everything, and grab that scraper to gently pry the piece off the wasteboard. OR, leave it there if I want to test-fit another part in it, or if I want to measure some dimension on the part. I will often leave the part on the wasteboard, regenerate a toolpath with lower stock to leave (possibly negative values, if a pocket needs to be a bit larger than I had anticipated for a perfect fit), and run that additional toolpath. If I had a dollar for everytime I prematurely removed the part from the wasteboard, only to realize 2 minutes later that I needed to run an additional finishing/adjusting toolpath…

- Regarding leaving the machine turned on between jobs: I will usually leave it on if I know I’m going to run the next thing within minutes OR if I can’t risk any subtle shift in the zero (but honestly, in 99% of cases for me, re-homing is no issue. It might even be beneficial since there is always the remote possibility of a lost step in the previous job, and re-homing would fix that). I have inadvertently left the machine turned on for hours before, and apart from moderately hot steppers, nothing happened (yet I prefer to turn it off when I can, it makes me sad to think of those stepper motors struggling at their max power to just keep the machine in the same position. They’re like sharks, some can stay motionless, but moving is what they do best).

I’m pretty sure I forgot things I do without even thinking (yet another reason why I should probably write a checklist someday), but this post is long enough as it is…

So what about you guys ?