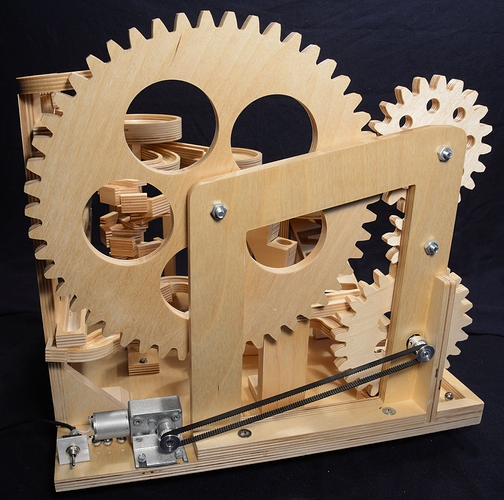

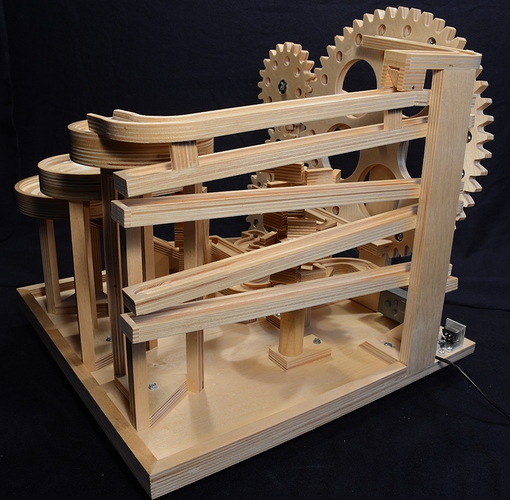

MARBLE MACHINE

Photos don’t do it justice - please watch the video, with sound ON!

Conceived 2 days after the contest was announced, it’s been a crawl/walk/run/mad dash to get the project, glamour-shots and video done by the deadline. Having never done gears, I thought they would be the hardest part, but they turned out to be relatively straightforward using a free online gear generator (link below).

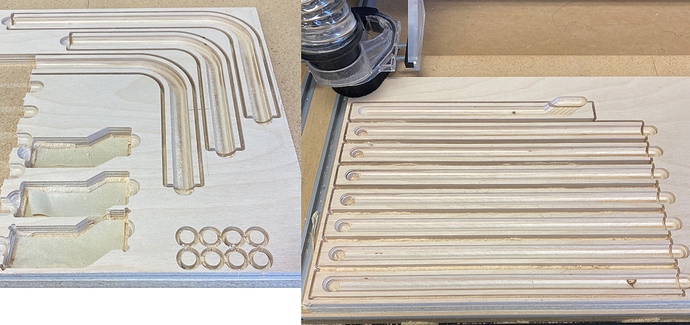

The hardest part was getting the marbles to load, not fall out on the ride to the top, and then dump out consistently at the top. Gravity keeps them in place for the ride, because the gear rack tilts back 4 degrees. Then through trial and error I machined “divots” on the inside edge so the marbles fall out at the top. [Note: The “better” way is to drill the marble holes on an angle with a Forstner bit in a drill press. But who wants to use a drill press for 30 holes when they have a CNC???]

I had no particular plan. After successfully getting the lifter mechanism working, I just made it up as I went, adding on stick-by-stick until all paths led back to the start.

FINISHED PROJECT PHOTOS

DESIGN NOTES

- All parts cut on my Shapeoko XL (Gears, Tracks, “Vortex Bowls”, Spiral staircase steps, Zig-Zag, Left/Right gate, etc.), with the exception of the base, legs and feet holding up the features.

- I later modified the small vortex bowls by plugging the single hole and cutting double holes to turn them into “randomizers”.

- I arbitrarily decided to make it all fit inside a 16x16x16 inch cube.

- Added a couple idler gears just because I could and I like the way it looks.

- 100% baltic birch, with 2 coats of Shellac.

- 12 VDC, 9 RPM motor from Amazon

- Pulleys and stock Z belt stolen from my Shapeoko maintenance kit.

- 3/8” steel ball bearings (a.k.a. “Marbles”)

- Through trial and error, 4 degrees seems to be the magic number for the slope on everything. Less and they didn’t roll well. More and they roll too fast and jump the tracks.

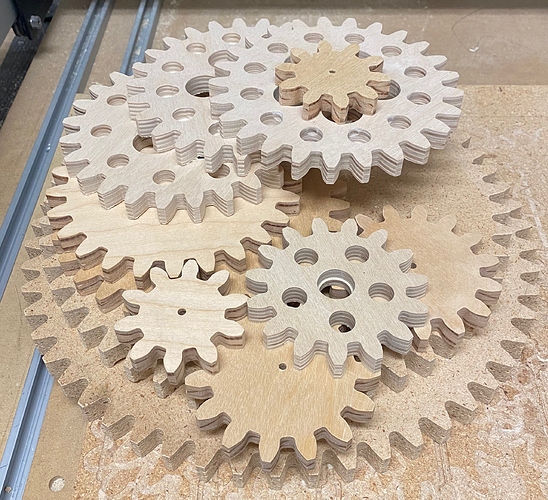

- Gears designed here: http://www.jeromeleary.com/gears/ and exported as DXF files, then imported into Carbide Create

- Marble Transfer Rate: 90 per minute; 5,400 per hour.

THINGS I LEARNED

- Gear Ratio vs. Number of marble holes matters. A lot. The first version of the drive gear had 25 teeth and 12 marble holes. The big gear had 50 teeth and 20 marble holes. So the gear ratio was 2:1, but the marble ratio was smaller, and the drive gear delivered 2 more marbles per revolution than the big gear could accept. Result? Marbles all over the workshop. Solution? A new drive gear with 10 marble holes instead of 12, so the gear ratio and marble ratio are now both 2:1.

- The 3D “Vortex bowls” forced me to get off my butt and learn the 3D modeling tools in Carbide Create Pro. The smaller vortex bowls have rounded bottoms. The larger one has a flat/angled bottom. Both versions seem to have good “action”.

- It is a law of nature that when dropped, Ball Bearings will seek the most inconvenient place in the shop, usually under my 500-pound Powermatic 66 table saw.

- I do not like the smell of Shellac!

THE BONEYARD, a.k.a “THE ISLAND OF MISFIT GEARS”

Prototypes, extras and mistakes:

A FEW CONSTRUCTION PHOTOS

Gears:

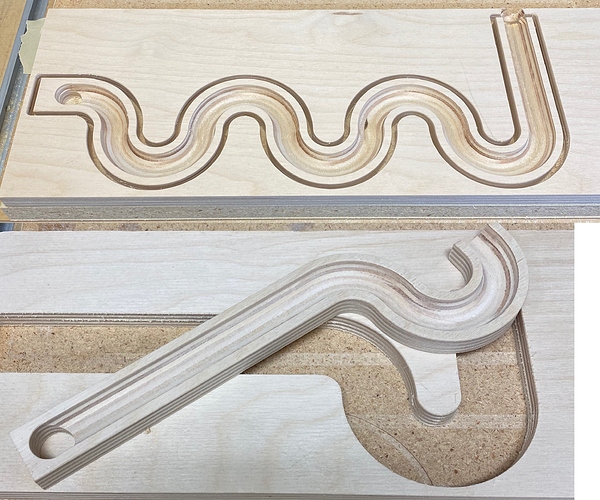

Tracks:

Vortex Bowls:

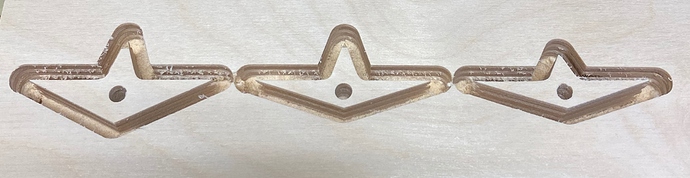

ZigZag and Gear Bracket:

Left/Right Gates Prototypes:

Spiral Staircase Steps:

Shellacked parts, ready for reassembly:

CARBIDE CREATE DESIGN FILES

Marble Machine c2d files.zip (2.4 MB)

CUTROCKET LINK: