I’m new to CNC and just got my Shapeoko 5 a few weeks ago. I grew up framing houses with my dad and he taught me how to use every kind of hand and power tool. I’m now in the software industry and enjoy combining my digital and tooling skills to produce physical things. While I’m new to CNC, I have a lot of experience with software development, 3D printing, and vertex-based modeling.

My parents built a cabin on a mountain in Wyoming in the early 2010s. In 2020 they retired and moved south. I have seen a few topo map cuts on social media and had the idea of making a topo map of the mountain where they built a cabin. This took quite a bit of research into data sources, GIS concepts, various ways of creating toolpaths, and physical testing.

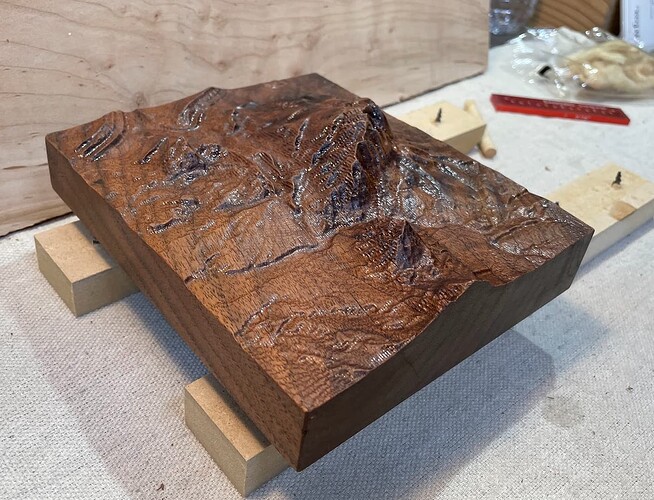

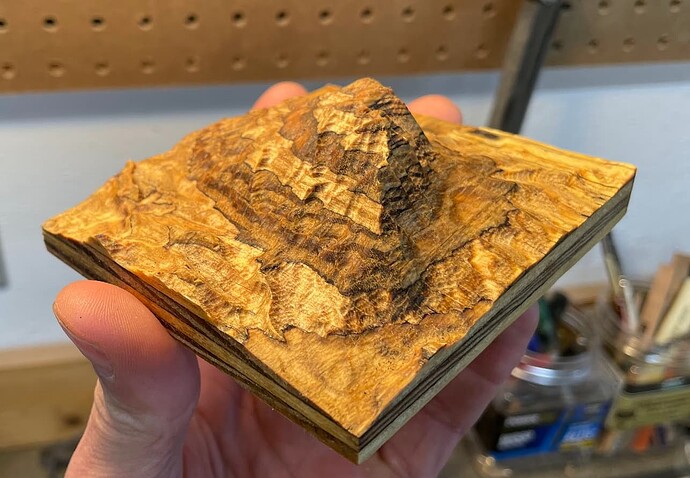

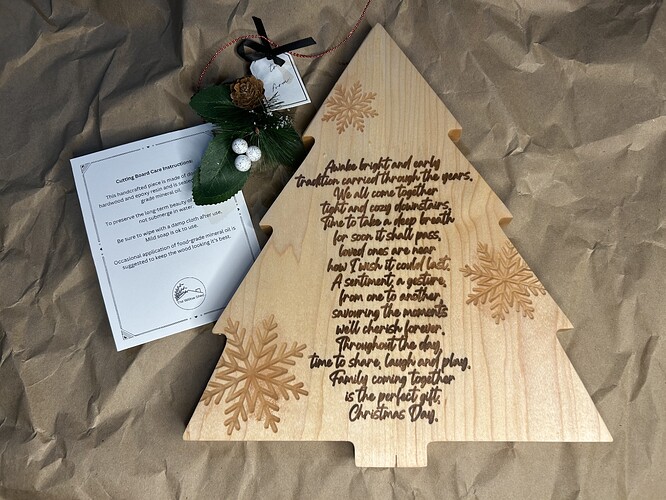

First, here’s the “near-finished” piece, which was drying in this photo, hence the inconsistent sheen. I have a few more coats of oil finish and then I’m going to laser engrave the name of the mountain on the side, my logo on the bottom, and put little leather footpads on the bottom:

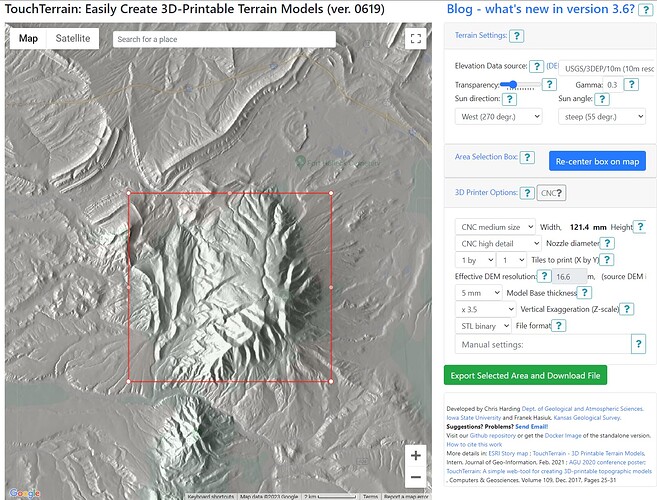

I started by experimenting with the most popular data source: Touch Terrain. It spits out STL files, which I am familiar with from 3D printing. While it’s a great tool, I didn’t end up using it because you have to do a lot of “hoop jumping” to get STLs into a millable format. But it’s worth mentioning for other users.

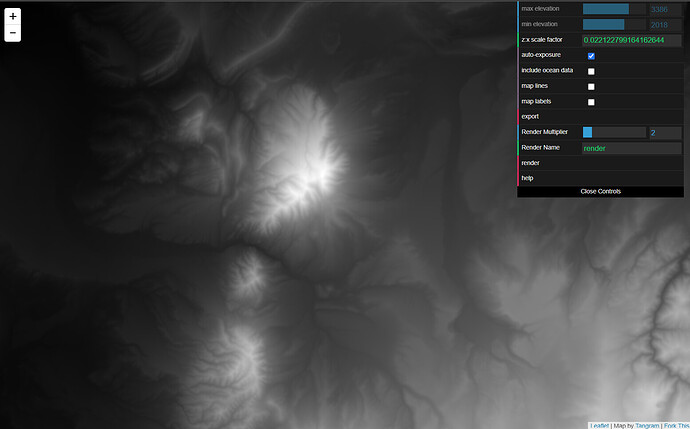

Instead, I used a data source called Tangrams which spits out grayscale heightmaps. I’m familiar with using heightmaps because I’ve done a lot of video game development and these are often used to create terrain meshes in video games. Carbide Create Pro can generate rough and final tool path passes from a heightmap!

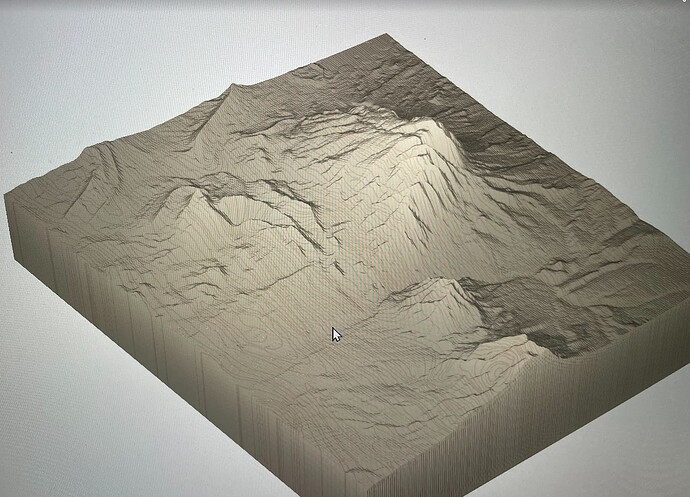

I pulled various crops of the mountain area into Photoshop and other tools and experimented with how much area I wanted to represent and how much to exaggerate the elevation. I found that slightly blurring the image and exaggerating by about 2x gave me a good balance of distinct features that didn’t have too many sharp points or stepping due to the exaggerated Z.

With Touch Terrain, you can choose the exact exaggeration but in Tangram, you can’t. Heightmaps basically use the concept of “exposure” since the grayscale represents relative height not absolute elevation. Instead you have to experiment with the base height and absolute height. A little pro tip is to import that same height map like 5 times and increase the height by 1/16" or 1/8" each time and run simulations of each in the same file until you get an elevation that “looks right”. Then delete all the other heightmaps that you don’t want. Also, NAME THEM BASED ON THE HEIGHT. Once you hit “done” you can’t re-edit the heightmap in Carbide Create Pro (feature request: please allow editing). So creating multiple is a workaround. Note that I obviously care more about aesthetics than geographic accuracy.

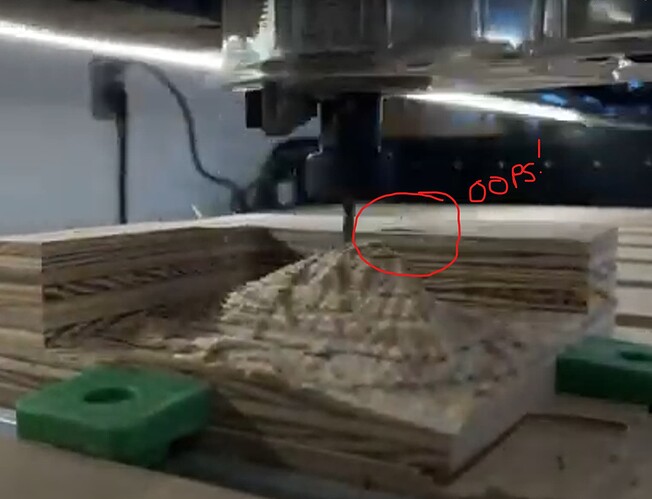

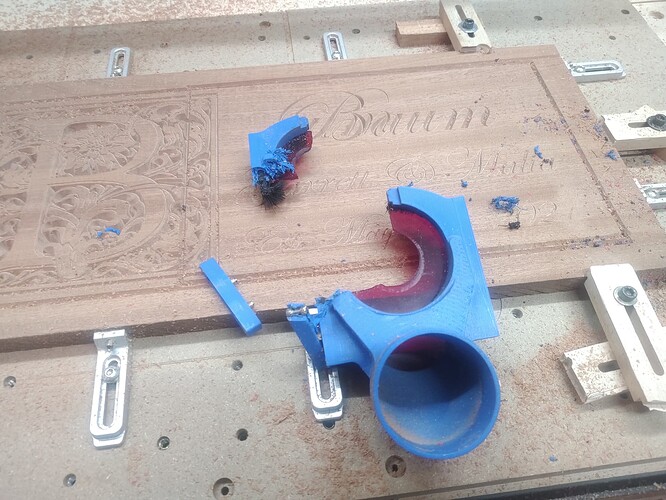

Once I had figured out the data sources and tools, I cut my first test in cheap plywood. The biggest problem I had here is that my 1/8" ball mill has a really short shank and my router head kept running into the unmilled wood. On future cuts I would remove wood around the piece with a 1/4" downcut first to give the head plenty of clearance:

Despite the head crashing into the wood on every pass, the test cut turned out decent:

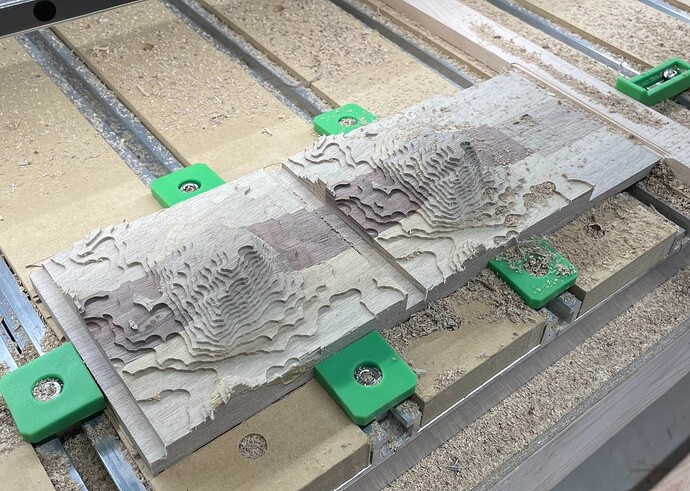

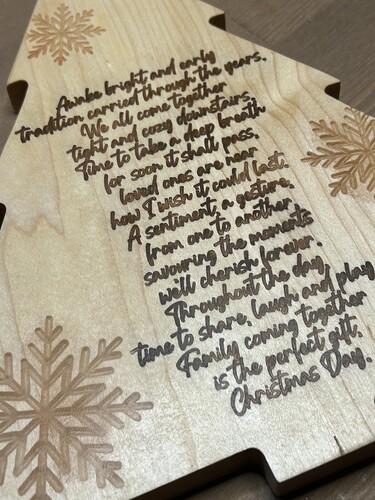

For my next experiment I laminted some cutoff walnut pieces together to create enough surface area to do a couple more. These were cheap tests but turned out nice enough to give as gifts to some of my other family that love this mountain… Notice on these that I milled away any wood in the rough pass that might hit the router head on the final pass:

Now that I had the process pretty much figured out, it was time to test it on the more expensive solid chunk of black walnut. I got this big rough cutoff from my hardwood supplier and flattened both sides with the McFly surfacing bit:

I oriented the wood so the finishing pass would be as aligned with the grain direction as possible, and so that the big divot in the side of the wood chunk would be milled away to a lower elevation area. Here’s the simulation (yes I took a pic of my screen because I was in a hurry)

It took hours to mill down the rough pass with a 1/4" downcut. Also I had to leave the vacuum pretty high so it didn’t hit the peak so it made a mess:

And the smoothing pass. For the distance between passes, I divided the mill diameter (1/8" ball end) by 4 and rounded that down to 0.03". It’s precise enough that I can see the original, raw sampling data so going more precise with your tool or pass width probably won’t improve finish by much:

To clean up the piece, I used a plastic brush to smooth toolpass lines and “fuzz” bits, and a green scratchpad to smooth it up. I am finishing it with Watco Butcher Block oil because I’m out of everything else and can’t get it in before the holidays.

So there you have it. I’m not including files here because my files were very specific to the place and this unique piece of wood. But hopefully I’ve given you enough information to make your own files and topo cuts of a place that is meaningful to you or your gift recipient!