RC Sport Plane

I am not sure if this project qualifies for this contest. The design work was performed Nov-Jan, parts were cut in Jan – Feb and assembly happened in Feb and March. If not, I can delete this and just move it to the project gallery. Let me know.

Here’s my method of using the Shapeoko to cut 2D parts to create a 3D RC plane! This is a project that has been in the works since last November when I bought an XL machine. This is the second plane I have designed but the first one where I cut out the parts on the Shapeoko.

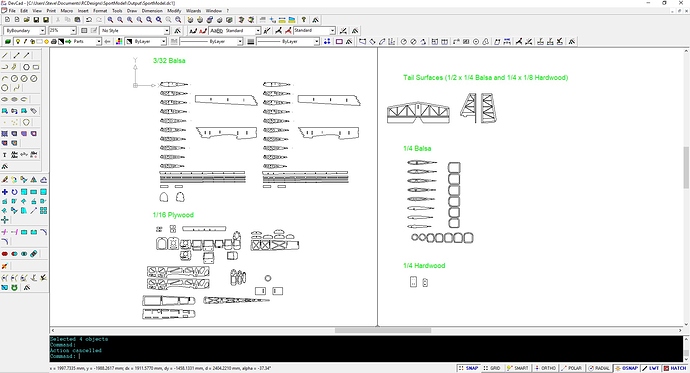

Designing:

I first decided on the basic parameters. For this build I wanted to create a good all-around sport plane to fly at my local RC field with others. I wanted a mid-sized plane that is easy to cart around and store. And electric powered like all of my planes and able to use batteries and other components that I already have. I wanted to use 3/32 and ¼ in balsa and 1/16 in plywood for the main construction materials. Based on other existing designs and knowledge, this lead me to a plane with a 55-60 in wingspan and a target weight of 4 to 5 pounds.

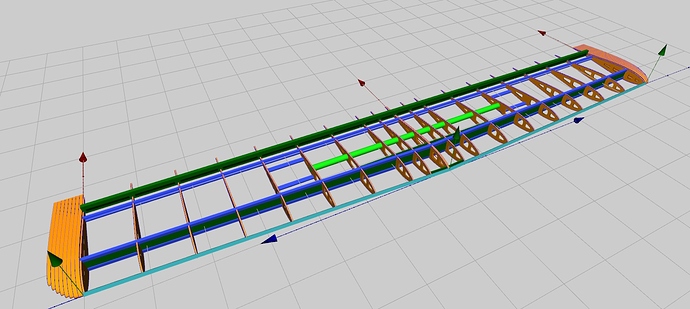

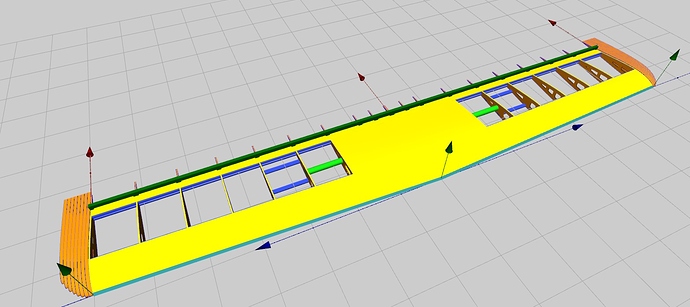

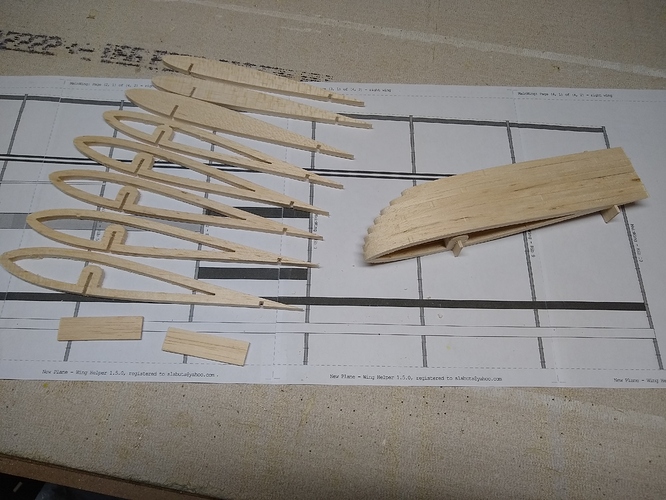

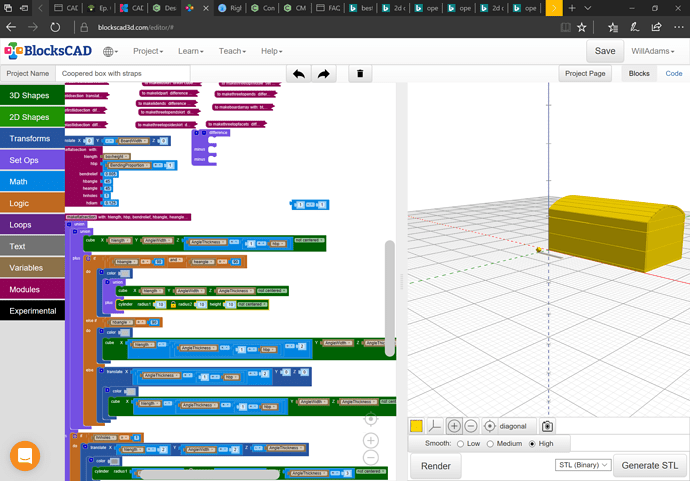

I used 3 different programs to help with the designing. WingHelper (https://www.winghelper.com/default/) , devFus and devCad CAM-Pro (http://www.devcad.com/eng/default.asp) I started in WingHelper to create the wing. This program basically allows you to specify and visualize a wing on the computer and will generate the needed parts in a DXF file. You can specify almost any airfoil and many different wing configurations. I settled on a 59 in span with an overall wing area of 577 sq-in.

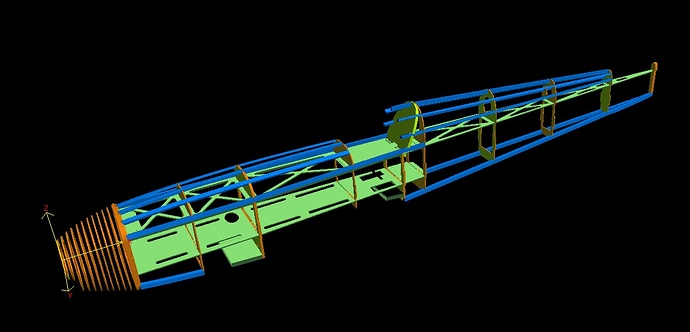

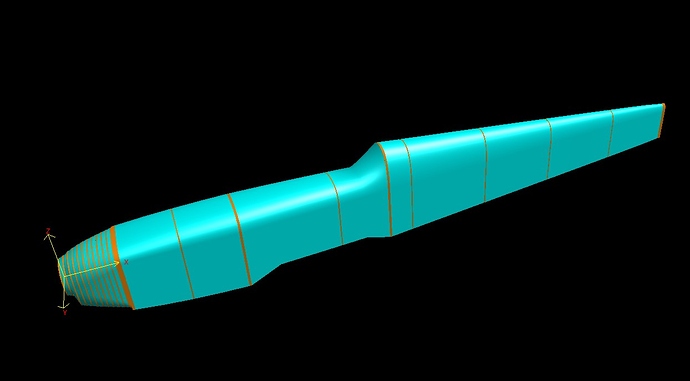

I used devFus for the basic fuselage design. Overall length and width determined by fitting in existing components and basic RC plane design theory for my chosen plane type. (There are many good books…) Like WingHelper, you specify many parameters and can “see” the design on the computer in 3D. I then outputted the needed 2D parts in DXF format.

Final designing was done in devCad. It’s a general purpose 2D cad program. I fixed and change things that I was unable to do parametrically before. I also created the stabilizer and rudder.

SportModel.dxf (1.5 MB)

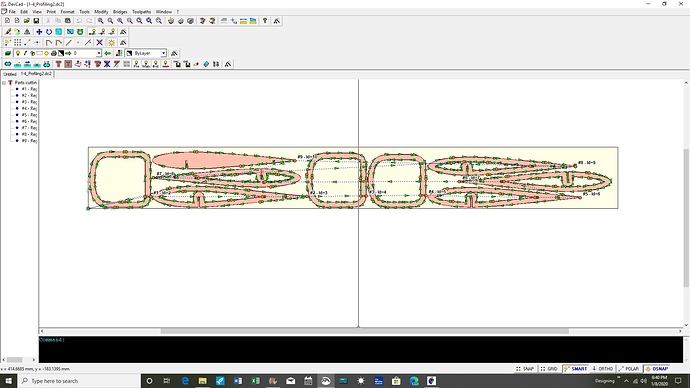

I also used devCad to do the CAM work. It has wizards to help with parts layout and creating the tool paths. They work quite well and you can change anything that isn’t exactly that you want. I did not use the auto generated tab feature because they were too often placed in a poor place. It was quicker to assign them individually. devCad supports a number of gcode post processors. There is not one specific for the Shapeoko, but the generic GRBL one works fine with Carbide Motion and the Shapeoko.

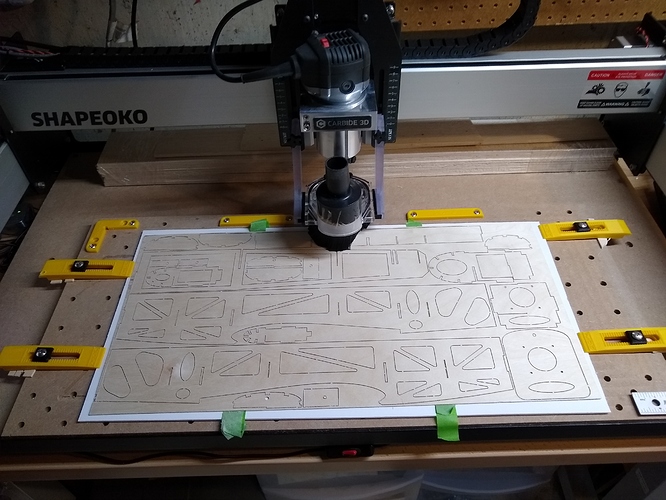

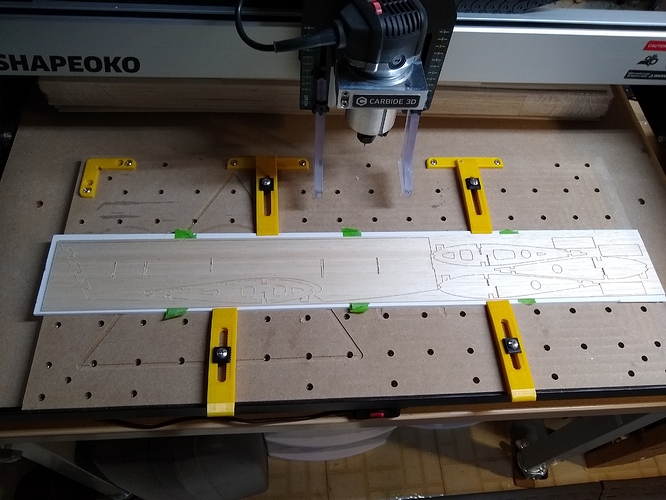

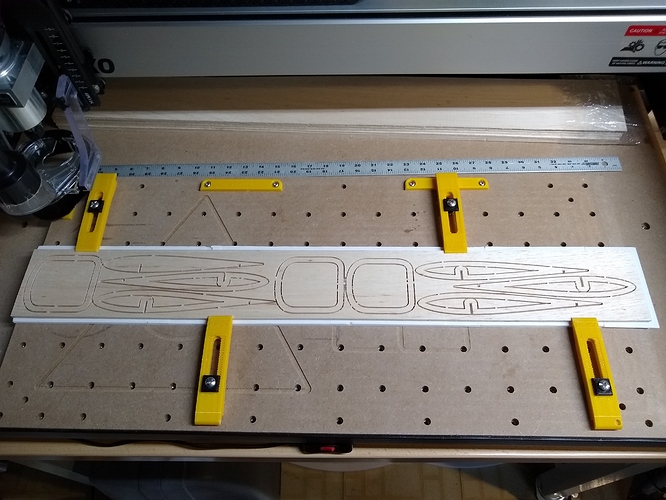

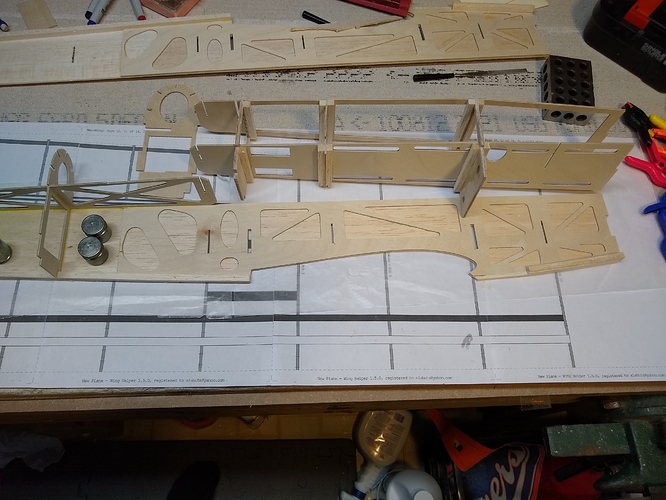

Cutting:

All parts were cut on my Shapeoko XL using Carbide Motion. The parts made from 3/32 balsa and 1/16 ply were cut using the tiny Carbide3D 1/32 flat endmill (#122). The ¼ in balsa was cut with a 1.5 mm flat endmill that has an 8mm cutting height. One thing I was worried about was breaking these small endmills in the waste board. What I did was use a piece of Dollar Tree foam board as a supplemental waste board. This worked fine but my depth of cuts needed to be extended some to cut all the way thru all of the parts. I guess the foam is not 100% flat. I used the tape and CA method to hold down the ply and it work well. I tried the same for the balsa, but it would break when trying to remove the tape after cutting, so I just clamped them down together. I copied the default softwood cutting settings for my endmills found in Carbide Create into the devCad software for use. I was able to increase the cutting speeds while cutting in Carbide Motion by at least 50% with no problems. Since I was more concerned with the quality of the cuts, I did not try to speed up any faster than this. I am sure I could probably still double the cutting speeds.

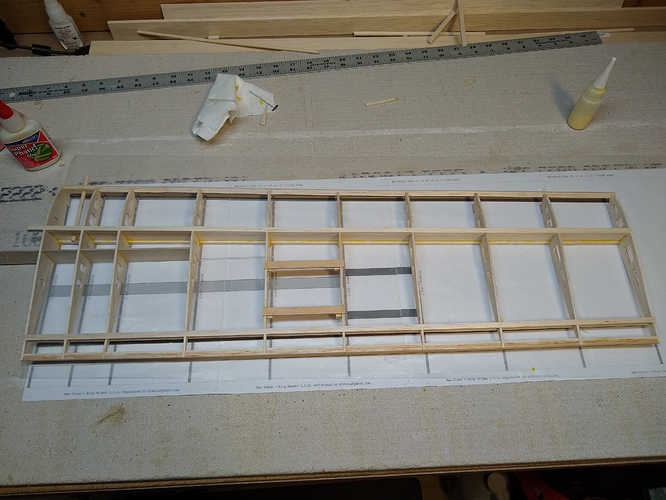

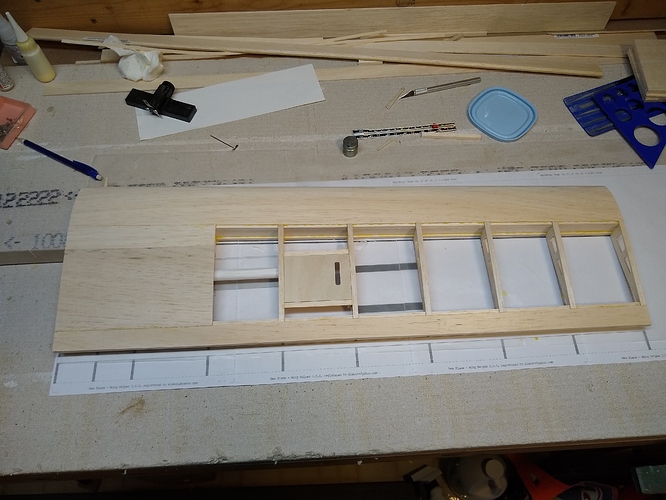

Assembly:

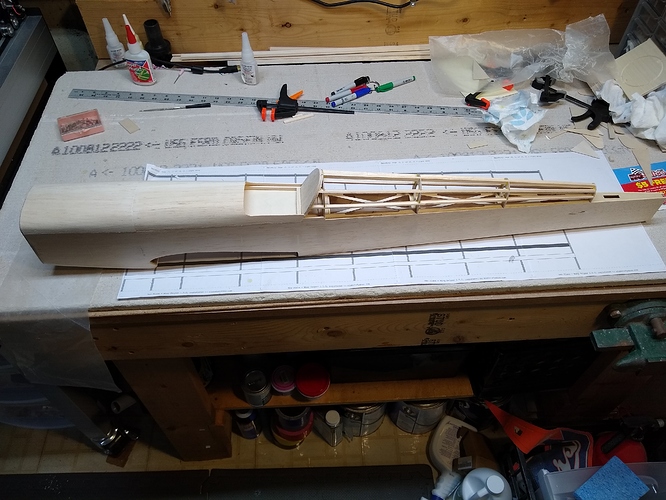

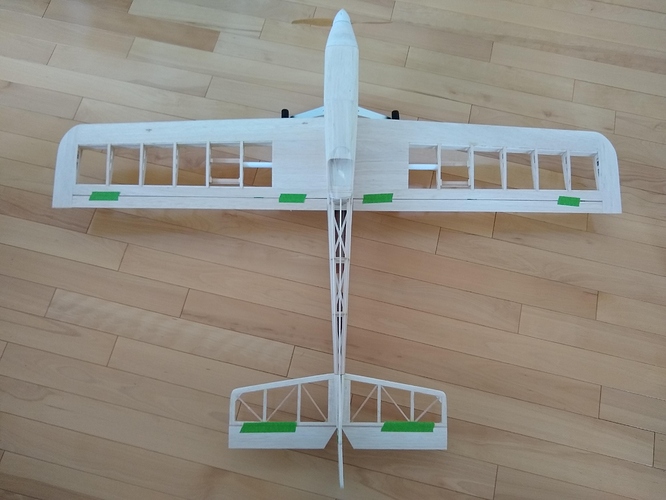

Started with the wing. It’s built mainly with the 3/32 balsa parts. Assemble the framework ½ wing at a time. Sheet the bottoms, join together and add the wing tips. Strictly glued together mainly with Titebond and some CA when a quick hold is needed.

Fuselage assembly is a lot like the wings. A lot of self-aligning and tabs… Again glued together mainly with Titebond. Some CA and Epoxy as well.

Final Assembled Structure:

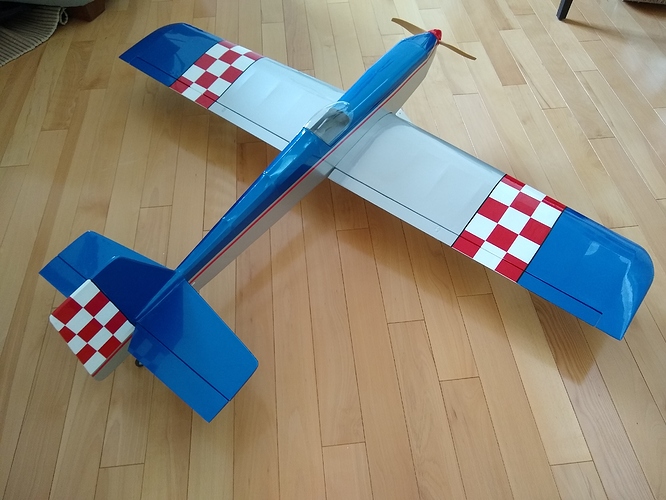

I used iron on covering for the finishing. It’s light weight plastic film with adhesive on the back. Final flying weight is a little under 4 lbs. I have now flown a couple of times and it flies pretty well! Still some tweaking to do, but I am sure I’ll be flying it for years to come.

After the first flight. Still in one piece!

(hint hint)

(hint hint)