WillAdams

May 13, 2024, 3:49pm

1

This is in response to @stra04 's post at:

Before seeing this forum this morning, I emailed the support team asking for help understanding a few features within the Modeling Tab pertaining to importing and working with STL files (I will post the email with pics below). Although I am a fairly accomplished woodworker, I am considered to be an extreme novice in CNC. I have always realized the value of using them for my projects, but I never had the money or the time to purchase one before. Finally, I purchased my first machine, a Shapeoko X…

I wrote up a bit on this at:

The difficulty here is that one needs the underlying 2D geometry, and it needs to usually represent a region in multiple ways — here are the basics of this:

https://willadams.gitbook.io/design-into-3d/2d-drawing

and also see:

This came in from support difficulty in getting a purchased image:

[image]

to cut as desired.

We will review the specifics here.

and:

I see in your recent e-mail to support that you have an STL — that of course greatly simplifies things, see:

https://my.carbide3d.com/gswccpro/07/

and also see

First, configure the stock:

[image]

Draw in the geometry for the bowl and place as desired:

[image]

Inset by the desired width of the rim of the bowl:

[image]

[image]

Offset to the outside of the bowl by endmill diameter plus 10%:

[image]

[image]

Draw in geometry to define the stock (since we’ll be working subtractively):

[image]

Go to the 3D model tab and model the stock:

[image]

Select the geometry for the inner curve of the bowl and model it:

[image]

[image]

Then im…

and

as requested on support…

Given an STL file:

[image]

which one wants to cut out as:

[image]

one first loads it into Carbide Create Pro:

[image]

which previews in 3D as expected:

[image]

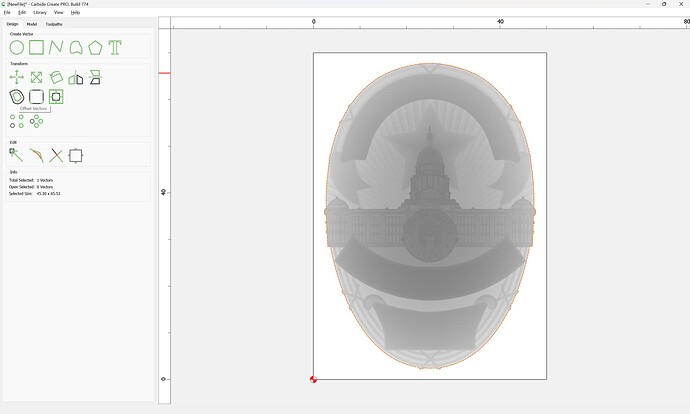

When an STL is imported, the perimeter will be traced:

[image]

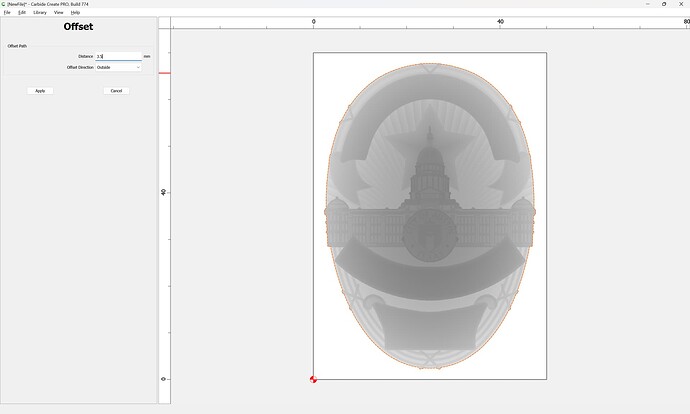

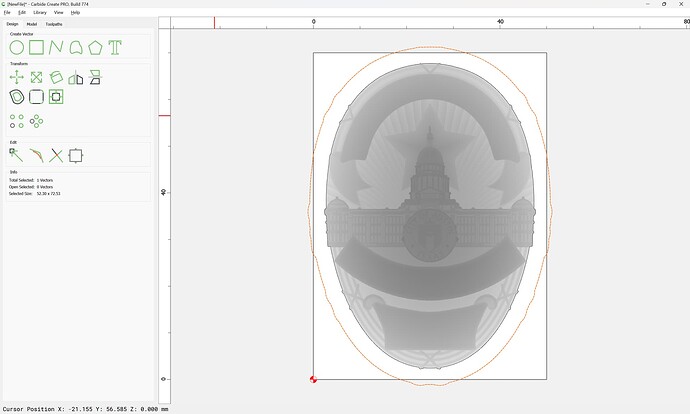

Assuming one wants to cut around the 3D object, one offsets from this by endmill diameter plus 10% or so:

[image]

[image]

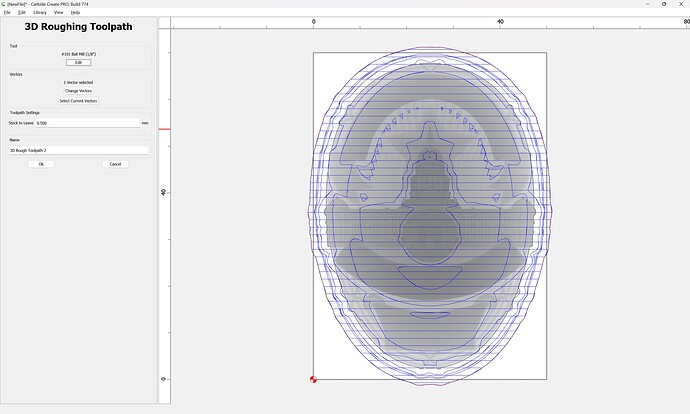

It is then possible to assign a 3D roughing toolpath using this offset geometry:

[image]

[image]

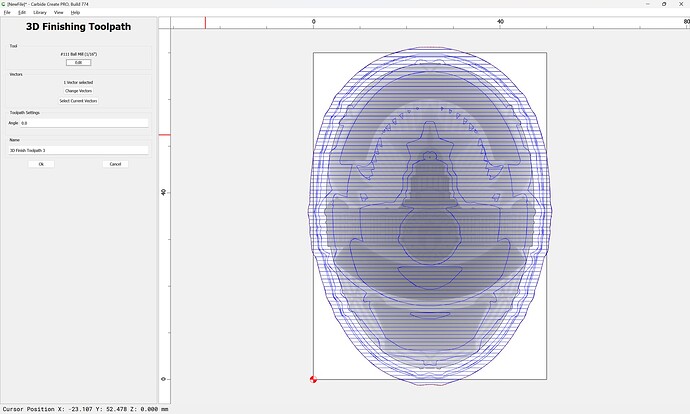

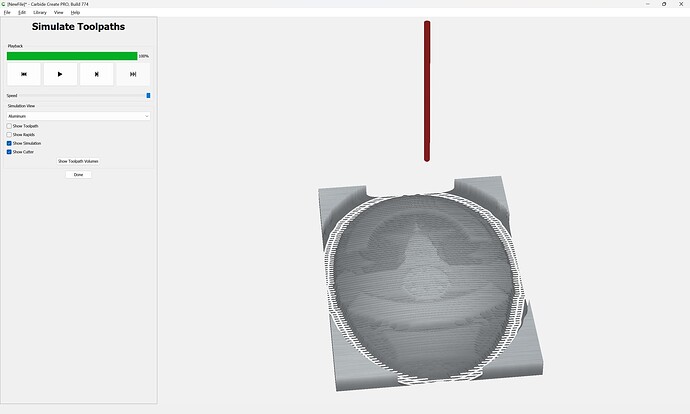

Then a 3…

We should be able to work through this with you on support.

WillAdams

May 13, 2024, 10:29pm

2

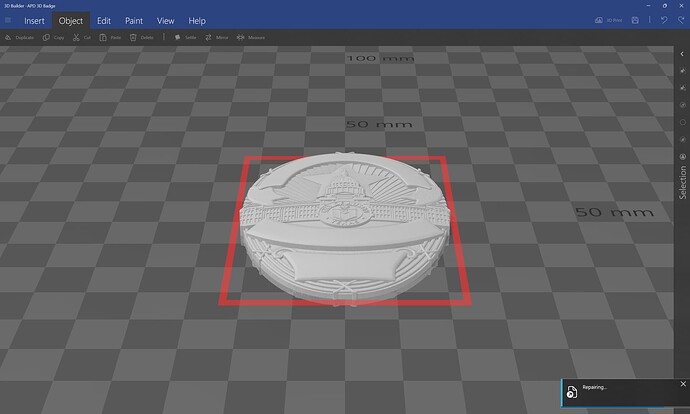

Given the STL file:

after repairing it:

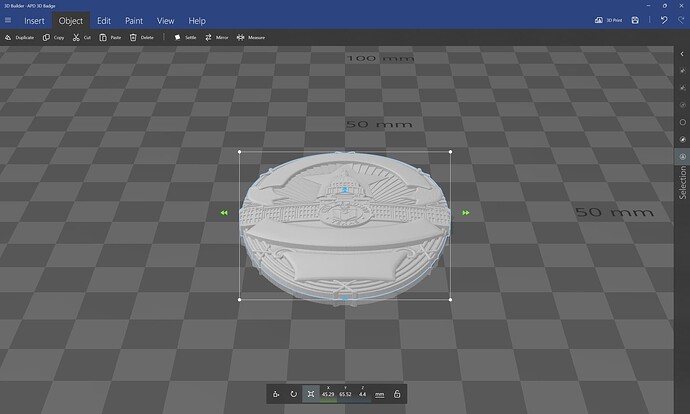

we can then get the dimensions:

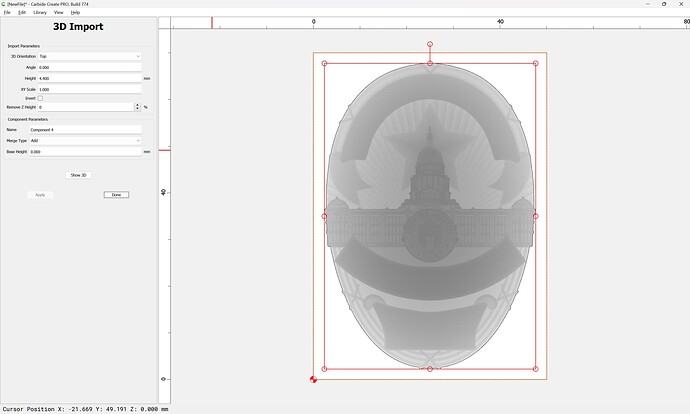

and import it into Carbide Create:

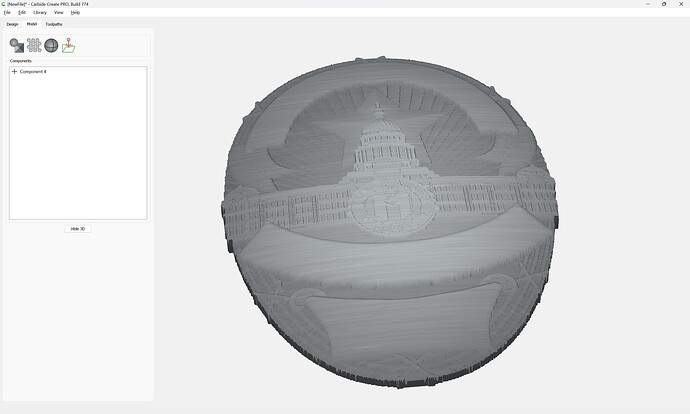

which shows us the 3D model thus made:

To cut the file out select the auto-traced geometry:

and offset to the outside by the endmill diameter plus 10%:

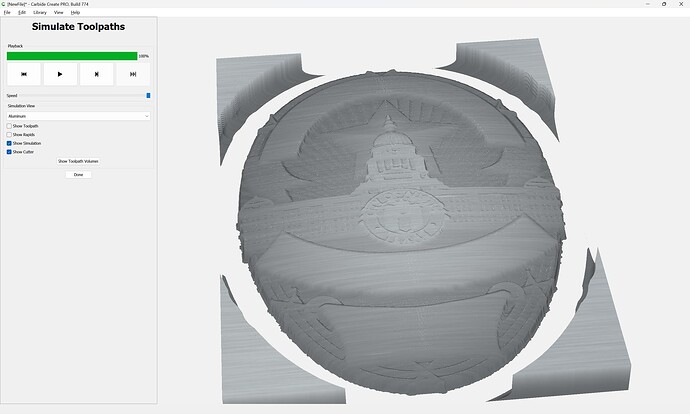

and then apply 3D Roughing and 3D Finishing toolpaths:

Going down to the smallest tool sold by Carbide 3D and increasing the stepover we arrive at:

1 Like

stra04

May 16, 2024, 11:58am

3

Thank you. I think I understand. I have been reading the articles you recommended and am gaining a better grasp of things. The problem is that I mostly only have weekends to reply or study up on the art of CNC. However, from reading through this reply, I do see a few things I did wrong. I will try to adjust and see if I can’t replicate your results working with the file. Thank you so much for the incite.

system

June 15, 2024, 11:58am

4

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.