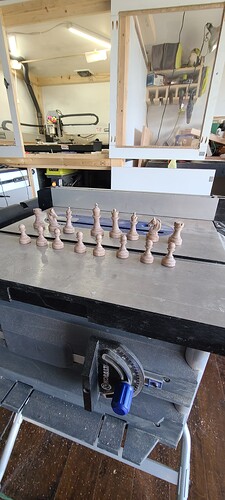

Finally after doing a bunch of reading and attempts at different methods I did some double sided machining and am happy with the result. What do yall think?

Super cool! Really like your layout/use of wood. Is this walnut? Will you make a matching set from a lighter wood?

WOW! Just wow! I do double sided, but nothing 3D like this. Now I want to learn to play chess

@MikeG yes it walnut 2" quarter sawn from a local mill. I bought the file design from ETSY and got in tough with the seller. Did a video call with him and building a friendship (he is from Rome Italy) and he helped make adjustments for free and I am helping him advertise and explain thinga in English to appeal to american buyers! I have a 2" thick quarter sawn piece of Sycamore for the light pieces as well as building a board out of the same lumber. Amazing how our hobby can build friendships that is what i loke about this forum.

@Ensalaco dont sell yourself short I have seen your work and it is amazing. I settled on the referencing pin method and used aspire. I want to do a guitar for my brother in law but havent pulled the trigger yet.

I do the reference pin too. I have installed a set of nut inserts on the center line of the X axis. They are 16", 18", 20", 22" and 24" apart and were located/drilled using the CNC to ensure they were perfectly inline with the X axis. Then I made a template with that same file, drilling holes into a piece of hardboard in the same locations. I place the template on my stock, mark the hole locations and drill on the drill press. My pins are 3/16 (10-32) threaded rod with a rounded point on one end that stick up about 1/4" - 3/8" above the spoil board. Just enough to line up the stock but not so deep that it makes it hard to remove and flip. You can then zero to that pin either manually or with exact location or even a G56, 7, 8, 9 code.

Cheers!

WOW!

What bit(s) did you use?

Was this designed in Carbide Create?

What did you do to keep the wood from twisting/warping while cutting?

Suggestion: Make a jig to hold the cutout pieces by the base (upside down) and carve something unique into the bottom. Maybe even embed magnets in each piece and the chess board so they snap into place when playing.

Good questions from @ColdCoffee Will you drill the bottoms and add weight or felt?

Are the piece tournament size and if so, do you know the weights?

Thanks for the tips I zeroed manually from beginning left corner of stock with a 1/32 bit for best accuracy. I set up the file to carve top side and reference holes on top @ColdCoffee rough cut was done with a 1/4"endmill from carbide #201 then did a finish path with a 1/16" diameter tapered ball nose bit I got from amazon. I did all this using vetric aspire as carbide doesnt accept the geometry of tapered ball nose bits and vetric has a flipping option in the setup. I also do not have the pro version of carbide so cant speak to that. As far as how I kept the wood from twisting and warping I was conservative with cuts and was fortunate to get a nice kiln dried piece of walnut 2"in thick walnut 6" wide to utilize.

After doing some research they are not perfectly to scale as a regulation size. Honestly havent decided if adding weights or felt on the bottom yet I do like the magnet idea, really i just wanted to try double-sided machining and found the file which made me remember playing with my great grandfather so just going from the pieces to a board and see where the journey takes me. I am also fortunate that I have a local supplier (30min) for hardwood supplies s2s s3s ect. That is chraper than the traditional rockler/woodcraft. To give you an idea I was able to get walnut and sycamore 6" wide 48" long 2" thick for under $50 with the size of these i can make 2 sets of pieces dark and light and 1 board.

As I am researching more on the game of chess my next set I will try to make fully regulation size and weight.

Also like the idea of carving on the bottom the diameter of the bottom pieces is 1.25" which is close to regulation from what I have read.

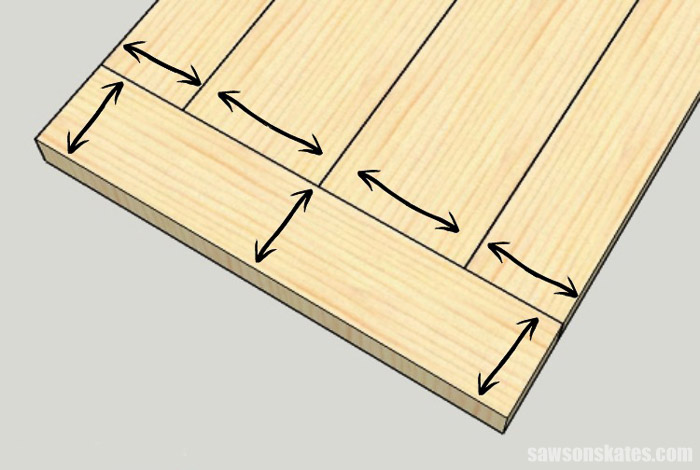

I know traditionally chess boards are done on the table saw, cutting strips of wood and flipping them to create the checkerd pattern. I would think it would be cool to do them as an inlay so as the main board doesn’t split due to climate changes (via the different types of wood being glued together that expand/contract at different rates). Maybe a walnut base with sycamore inlays would be cool.

Can you share the Etsy seller? My son is wanting to build a chess board and this is perfect. I would love to buy the plans.

CHESS / Cnc Chess / 3d Chess / Chess File / Router Chess Set / - Etsy. And like i said in the first post awesome seller as well. Key thing with the file is to pay attention to the initial size which he outlines and if you scale it ensure you scale XY and Z proportionally, (mistake i made on the test cut from scrap wood) @rnicolson

Been thinking of how to attack the board and doing some research. Found one idea that i was thinking of doing which is to put 1/16" or 1/8" dowels pins on all sides to minimize expansion and contraction. I dont know if it will work. I am still tweaking my inlay process. I probably over think things but am cautious before i go with expensive wood. One because i cant afford it lol!!

Wood selection will help. For board that you want to keep flat, look for quartersawn. If Rift sawn or flat sawn, make sure it’s not from the center of the log. Those will cup. They are easy to spot from the end as you will see curved grain lines (and will cup in that same direction)

To reduce expansion issues, try to keep. grain directions running the same way and not cross grain. If you want end caps, try making it a frame that it sits in instead, leaving it removable.

This picture shows the direction the largest amount of expansion occurs in a board regardless of species. Dowels will not stop this. For traditional chess boards, keep the direction of wood the same to reduce impact.

The supply I have is quartersawn so partially there i guess thank you for the tips. Any and all help!

You’re very fortunate to have a hardwood supplier nearby. We’ve got a few in SoCal, but most of the wood like this is imported from other states.

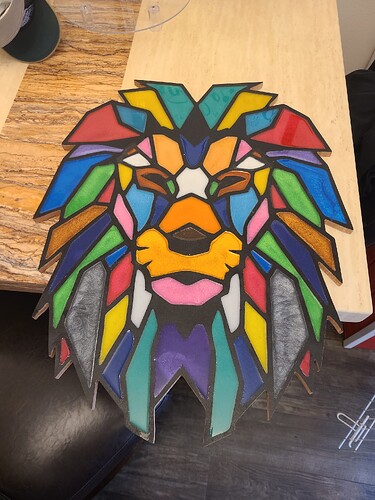

Here’s a couple of board ideas, though you must keep in mind that I suffer from enjoying working with epoxy.

From a eucalyptus tree I cut nearby:

And another albeit, no top coat finish applied yet:

@MikeG I really like that. I have played with epoxy and dont mind it at all, just time consuming lol.

Not sure what i am going to do yet, one of those projects that i dont have a solid plan just trying new strategies out. I am fortunate to find the seller nearby for the hardwood and really got lucky. I dont have Facebook but am in the Navy so talking to some friends that do woodworking and they helped link me up with the supplier. Networking has led me down to meeting great people and lucky finds. I was stationed in SoCal and remember having to rely on big stores so I know it is a struggle.