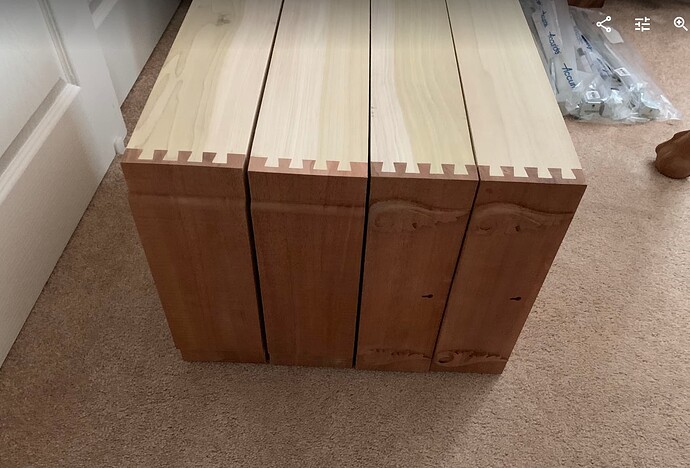

Wondering if anyone has been able to carve accurate dovetail joints, I’ve tried a few but they never seem to come out right. Any advise would be greatly appreciated.

I worked these up at:

and see:

for an example of a joint cut in pine.

That said, if you want dovetails, why not just do it by hand?

Any sort of joinery which involves cutting parts held vertically requires 3 setups:

- one to cut the parts to size/length and machine interior features

- one were 4 boards are secured on the machine (2 flat, and 2 vertical) to cut two corner’s worth of joinery

- a repeat of that with those 4 boards to cut the other two corner’s worth

It’s a lot easier to draw up and cut joinery as part of machining parts to length/width, but maybe that’s just because I was not terribly successful in my vertical fixture design — probably a better fixture (other folks have done some which look to work better) would help a lot.

Rebates are so easy that they are referred to as “The Simple Box”:

and there are lots of other possible techniques:

and I worked up a full-blind technique which I’m using for a project now:

Yes, I made several metal vises (2016) and a complete Chippendale desk on my Shapeoko (which contained dozens of dovetails) (back in 2019). Search for Chippendale and my user name for info.

Richard,

Thank you, that looks beautiful. I will keep at it and post any successful projects. I appreciate your input.

Now that I think about it…one piece of info. The cutters do have a tendency to pull out due to that long side taper…no matter how tight I tightened the collet.

The fix was to rough out the pocket with a 1/4" flat/square (or 1/8 inch) end mill first.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.