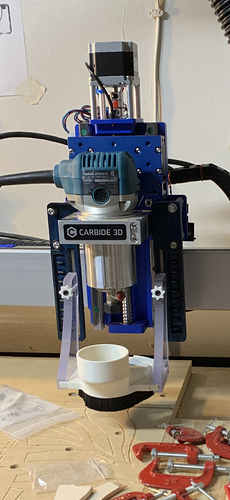

Now that the HDZ is installed looks like the suckit needs a bunch of (out of stock) parts if not total replacement for big bucks. Any alternatives available? Extraction is a Rockler w/2.5 in anti-stactic hose.

you’re in line for holding @Luke’s beer

Yep hit refresh every 5 minutes for the next few days like me

Rear Mount - Z Independent :

https://pwncnc.com/purchase?olsPage=products%2Fdust-boot-v2

Spindle Mount:

If you have a 3d printer, look at the PWNCNC option, you can download the boot from Thingiverse and buy the hardware kit off the store for around 30 bucks.

I had a Suckit boot on my Stock Z-Axis, and just finished setting up the PWNCNC boot - its very sturdy and mounts from the back, doesn’t require removal to change bits… I definitely rate it above the Suckit, and it only cost me ~$30 and $5 in 3d printing material

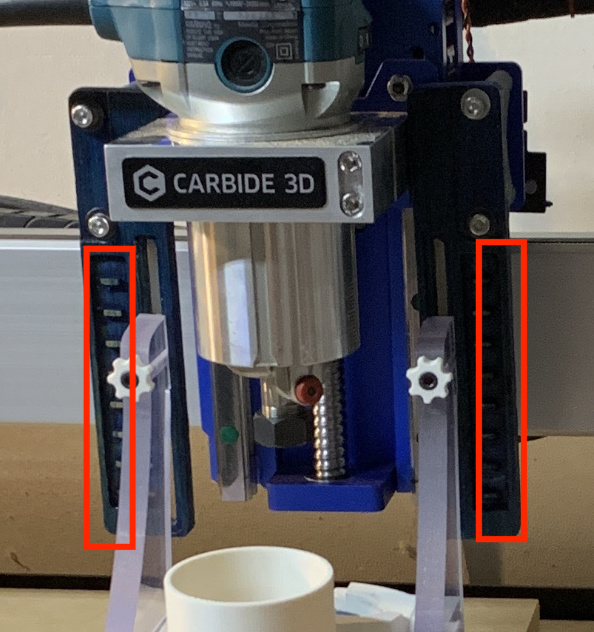

What I did when upgrading to the HDZ was I hacked my Suckit arms, and mounted them to the small metal ears that came with the HDZ using 3D-printed spacers. Worked fine (until I went down the route of redesigning and printing a complete custom dust shoe, but this is another story)

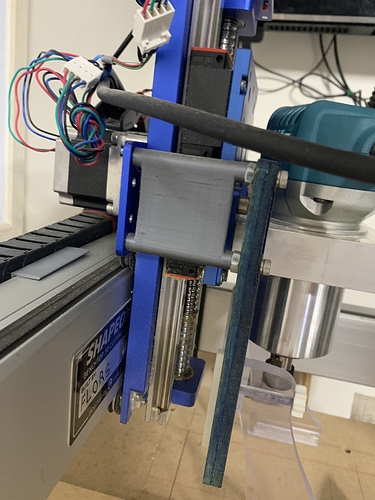

Your supports are polycarbonate? Mine are steel. Not saying the shapeoko/HDZ won’t handle it, but…

Also, I’ve already hacked up my arms to fit around a support bracket that I have on my current z-axis. My HDZ will get here tomorrow so I need to figure out how to mount my suckit. I didn’t get the ears from Carbide or the Suckit spacers. Seems like I saw files to make your own but I can’t find them now. Anyone know where to find these files?

Yes, mine were polycarbonate. Indeed I would not mess with steel myself.

The Fusion360 design files for the ears seem be to provided at the bottom of this

page?

Back in the day I made my own parts for this conversion, I made the supports out of bamboo plywood and painted blue

This might not be perfect but saved me some bucks!

Besides the 3d printed spacers and the machined supports, I needed 80 mm M5 bolts and the HDZ “ears”.

Yeah, I was thinking I can do something similar to that pretty easily. Might even get rid of the part that has the markings so that it doesn’t take up extra X travel.

Thanks, that’s exactly what I was looking for.

One thing I will point out with the PWNCNC dust boot is that it is excellent for sheet goods but it does reduce your z-clearance behind the spindle so even though your part won’t interfere with the z-axis, it may with the dust boot.

With that said, I still love mine and will recommend it. Just be aware of the pros and cons of every system.

Funny you mention this… I am doing a job right now in 45mm material (about 1.8") and the boot is hard against the top stop…

The ears are where you lose the X travel.

If someone wants to use my files, here they are, so you can make you own parts for the conversion.

You will need also 80 mm M5 bolts and nuts (4) and the ears.

HDZ_Dustboot_files.zip (146.1 KB)

This is for those who have the Suckit for the HDZ already (or are willing to make the parts needed), but want more airflow. This is a 4" dust shoe I designed based on the original Suckit dust shoe, but scaled up for a 4" dust hose.

I could be wrong, but it looks like the ears will clear the top of the side rails. I’m talking about removing the areas marked in red from the supports. That’s the part that looks like it would hit the side rails first. If I make it out of 3/8" or 1/2" aluminum (depending on what I have laying around) there shouldn’t be much flex.

This may be different in a newer version, but those ears hit the Y plates. That section you highlighted didn’t come into play (unless it’s wider than the ears).

Ok, thanks. I guess I’ll just have to wait until it gets here this afternoon and see what I can do.

Cole,

It looks like you had to add a bracket to extend your x limit switch as well.

Phil