Don’t count on me to always use the proper English terms either

I meant the inside of the conical hole in the router, where you insert the collet and bit. If dust gets in that hole and you then insert the collet in there, it will not sit nicely in the hole, it could end up being crooked, making it impossible to tighten it enough (whatever amount of force you use).

I’ve only just received my Shapeoko spindle with an ER20 collet today, so can’t comment there, but the ER-11 collet on my Nomad has never gotten any dust in it. I swap the nut and collet between 4mm and 3.175mm versions every so often, and never see any dust inside it at all.

The ER collets look different to your router’s collet so perhaps the design helps?

EDIT: That’s after over a year of cutting metal, wood and hdpe

I have been using ER20 collets in my spindle for about two years now, and while I never had issues with endmills slipping (well, I never had issues with endmills slipping back when I had a Makita router either, it must have been my collet-cleaning OCD helping back then), I still tap them lightly after I cut e.g. MDF, and dust does get in there (in the slots of the collet). The taper, not so much, but worth checking from time to time.

There’s an opening for the button at the top of the shaft which seems to admit debris if the chips from cutting are dust sized and the vacuum isn’t efficient enough to take them all away.

If the job you did “yesterday” was long and warmed the collet, router shaft and end mill, perhaps the thermal cycle was enough to start the loosening process. Did you check for tightness before beginning the job that the end mill slipped on?

I did. I even tightened it a bit more, but it didn’t seem to work.

It just happened again!

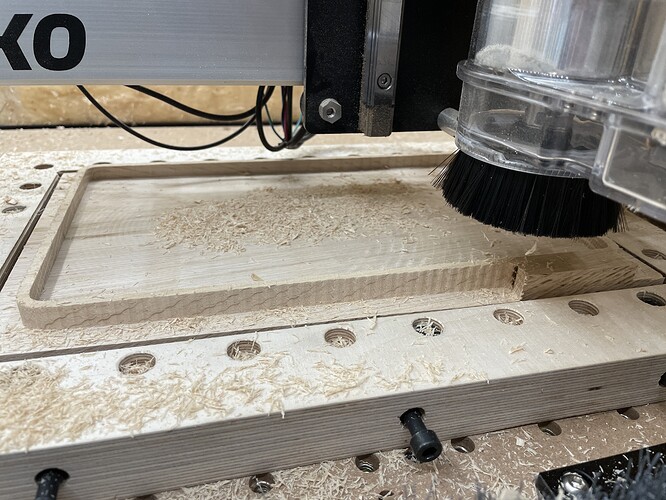

I took out the old tool, cleaned the collet and tightened the new tool and then this happened:

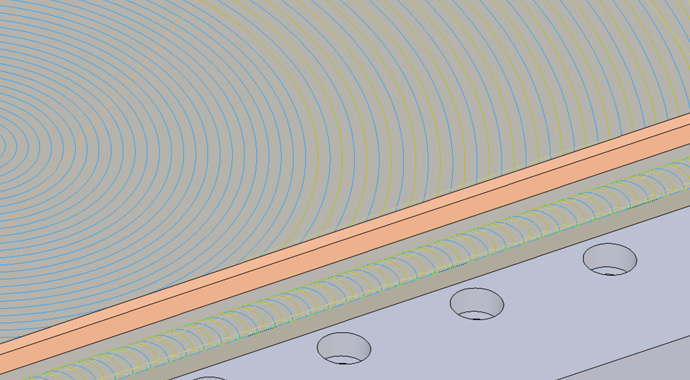

This is the path that it was running:

I’m not sure what to do here. Any guesses? Am I just being too aggressive in my cuts? It doesn’t seem like a thing that should happen?

Have you tried to confirm directly that the endmill is moving, either by measuring the protrusion when you’ve affixed it, or by marking the place where it meets the collet with a sharpie?

I’m quite sure that the endmill is moving. What else could be happening? Could the spindle be forced down? The wood is firmly placed on the wasteboard, so that’s not moving around for sure.

no but the piece could be pulled up if workholding is not good enough. I doubt this is the case here, is that a custom workholding jig I see ?

Can you share your cutting parameters ?

It sure is. The jig is working really nicely  .

.

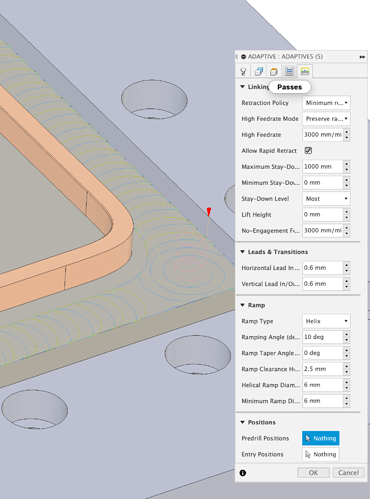

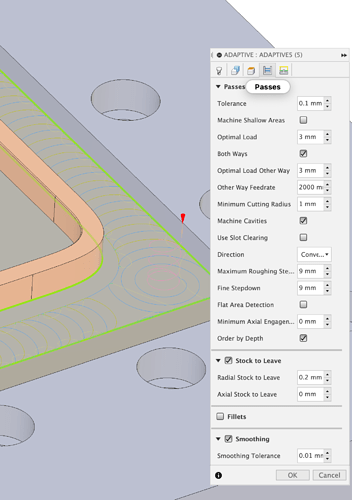

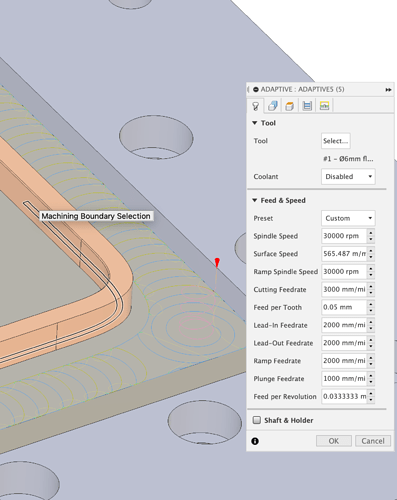

Sure. I’m definitely pushing it to the edge… probably over it seems:

I’d be curious to know what your speeds and feeds are, just based on the photo it looks super aggressive. if I were approaching the same job I would assume that I’d have a depth of cut of about 1mm for hardwood.

Yeah, 9mm depth per pass at 3mm optimal load is…a lot, I tend to stay in the 1mm optimal load ballpark when cutting deep adaptive like that.

It only comes to mind now, but you should check your zero after this happens, to establish whether you lost Z steps during the job. If you did, chances are it’s that upcut endmill pulling too hard on that poor stock

You should always have a spare collet onhand anyways, so I would just get a replacement and see if that solves the issue, because it feels like the collet is not gripping the endmill when under strain…

This is exactly why you should confirm it. Not being able to think of what else could be happening is a fault in thinking and not an affirmation of reality.

From my experience in manual machining, it’s an indication of chatter.

As mentioned previously, generally too aggressive of a cut. It can also be lack of rigidity, but that is caused by too much tool pressure, or again, too aggressive of a cut.

At least, that’s for metal. I assume the same stands for tree, but may be wrong!

Those scallops could be the result of the toolpath.

I agree that the cut is at least optimistic though.

If there’s enough vibration to move the cutter I’d expect the whole Z assembly to be vibrating too, maybe a video (with sound) of the machine attempting that cut would help?

Isolating fine thanks, new job is keeping me busy and occupied.

I thought those scallops might be the remainder of a roughing toolpath based on the pics posted

But I tried setting up a similar path in Fusion myself and the simulation shows the adaptive leaving relatively smooth walls so, no, it looks like it’s due to substantial deflection.

That’s what makes an experienced machinist experienced ![]()

There are some basic rules we can follow though about minimum feed per tooth to avoid just rubbing and maximum overall cutting loads for the machine. I’ve used Millalyzer to help with this to some success.

There is also @gmack 's excellent feeds and speeds spreadsheet which has a whole load of shapeoko specific knowledge which would be a great first place to check out this cut.

If there’s enough vibration to move the cutter I’d expect the whole Z assembly to be vibrating too, maybe a video (with sound) of the machine attempting that cut would help?

That’s a point I had not considered. I like the idea of having a video clip and sound made during the cutting process. It would certainly assist me to understand what is shown. My expectation is that changing the cutter for a new one of the same type, without out adjusting any settings, would lead to an improvement in the cut seen.

[/quote]

If it was my cut the first thing I’d do would be to either back off the optimal load to 1mm or 1.5mm or drop the max stepdown to 3mm or 4.5mm and see if the machine is happier at that lower load.

As above, well questioned, looking closer at the toolpath, you’re right, it’s not the adaptive, it’s deflection and the sheer size of the deflection suggests machine deflection, in my experience if you bend carbide that much it tends to break and fling high speed shrapnel at you…

You’re absolutely right that a blunted edge on the tool will make any issue with the toolpath worse. A cut with high vibration and chatter will also abuse the cutter and may well blunt it prematurely.

I guess this is what you get for trying to bore a 4.2mm hole with a 4mm cutter through 10mm of 6082T6 Aluminium, must remember to pre-drill next time[Screenshot 2020-10-12 at 23.22.17] I think the edge has gone a bit dull… [Screenshot 2020-10-12 at 23.21.44]

I’ve found in wood that I get a dark buildup when cutting woods with a high resin content such as maple which I can clean off with a tool cleaner or acetone. As for sharpness Julien has some close up pics in the ebook showing the structure of the cutter edge and bevels which are linked in this thread

Those are good pictures, I went and looked at my abused 201 under a better magnifier and saw the primary and secondary bevels you pointed out in your ebook. Here’s a somewhat poor picture using a cheapo USB camera thing, the primary bevel is still there but somewhat scarred and battered, if this was a plane blade it would definitely be off to meet the waterstone in that condition. [Screenshot 2020-06-12 at 19.38.05] [Screenshot 2020-06-12 at 19.40.47]

Since looking at those pics and inspecting some of my cutters under a proper magnifier I’ve learned what a new sharp and old blunt tool feel like to the thumb, at least for wood, still taking baby steps in aluminium.

Have you read gmack’s posts on feeds and speeds?

IMO, at least with wood, its more about the Shapeoko’s force and power limitations than cutter chip-loads (which were seemingly developed for much more capable machines and/or advertising purposes.) For yellow poplar and hard maple chip-loads of 0.0004 - 0.005 in/tooth have worked well for me with both 1/8” and 1/4” 2 flute carbide endmills. Since reducing chip-loads reduces both force and power requirements (and/or enables greater cutting depths to extend tool life), minimizing it seems like th…

And yes, hopefully holgersindbaek will soon be finding a way to run that cut without problems, I’ll be interested to see what works.