So, after trying to help @TX_diy with his belt tensioning woes, I thought I’d revisit this. (sidenote: is belt tension THAT important?)

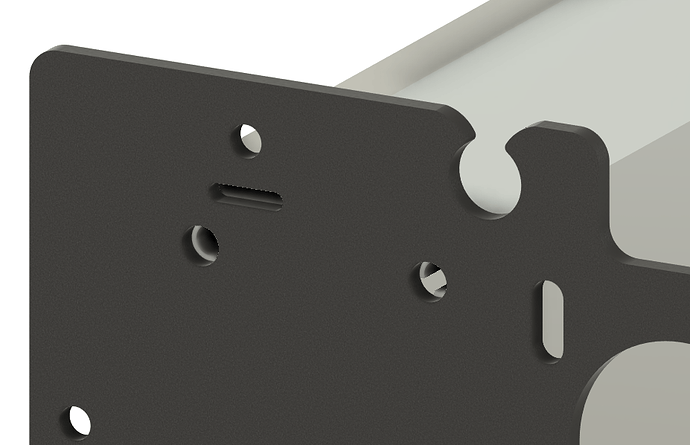

I am building (so slowly…thanks corona) an SO3 for my classroom. I had Y plates made that have a slot where the belts could exit.

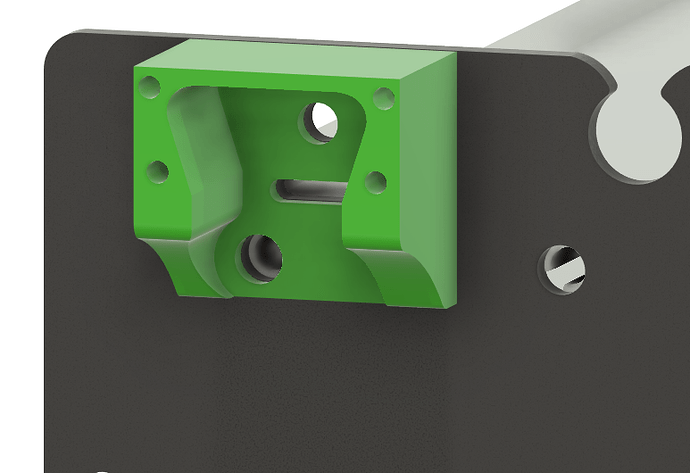

I stayed up way too late last night (inspiration hits me when everyone else is asleep) and here’s what I came up with.

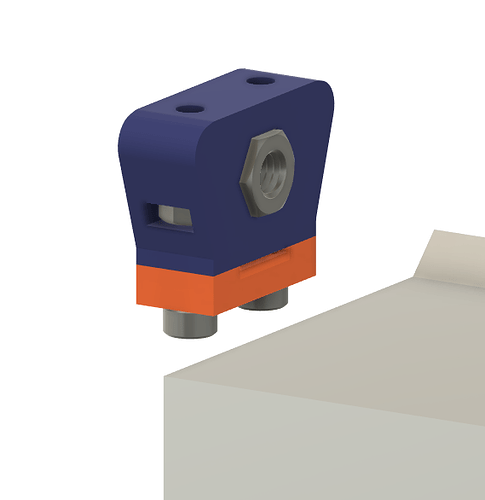

First, the base which is attached using the existing M5 tensioning clamp hole and one of the M6 extrusion mount holes.

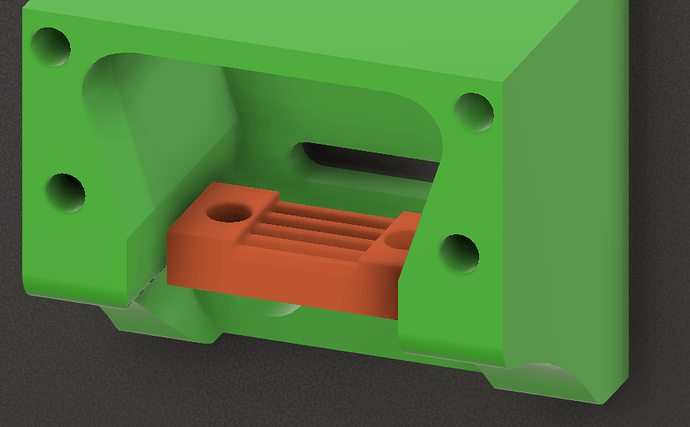

Inside the base track will ride the tensioner clamp.

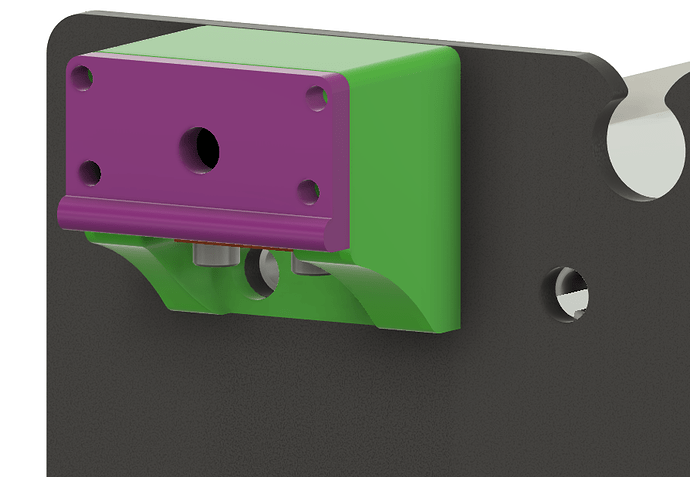

The belt will be clamped with M3 screws and this little thing holds the belt extremely well.

The clamp has captive nuts for the M3s, and an M5 nut on the back for tensioning.

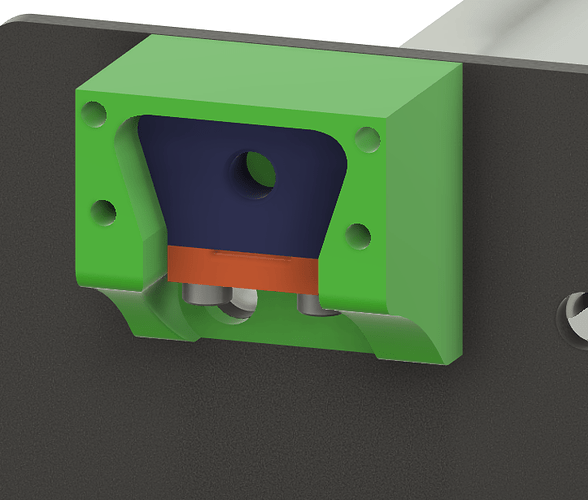

Finally, a cap covers it all. To tension the belt, all you need to do is turn an M5 screw through the cap to pull the sliding clamp.

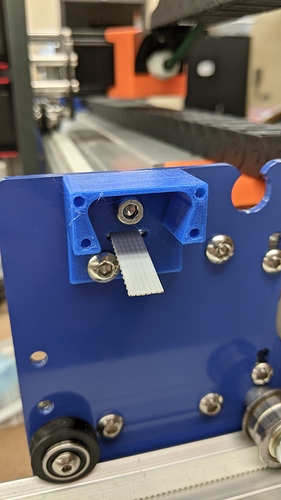

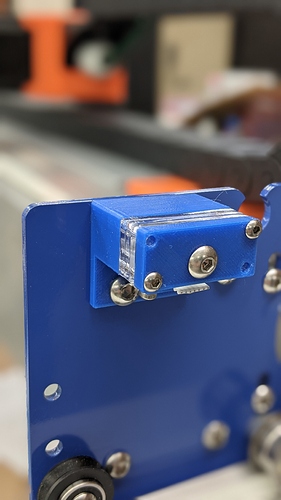

My prototype works really well.

Unfortunately, this method involves making a slot for your belt. Otherwise, it’s a pretty simple mod.

Thoughts?