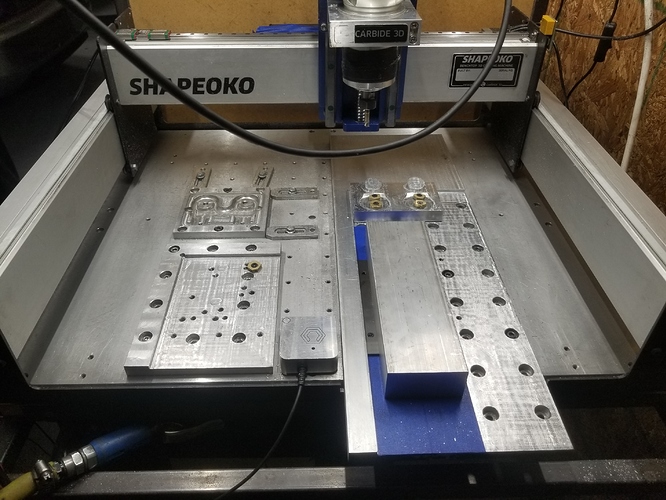

@Vince.Fab Got another question for you Vince. With all this metal cutting you do, and the use of a mister, how do you keep your rails clear of chips? How do you make sure you aren’t rolling over a bunch of them with your v-wheels, essentially damaging and ruining them?

That’s a post all in itself!

@Winters636 The best part about being able to machine aggressively is being able to control chip shape, mass, and exit directions. A few deflectors, well directed air blast and a broom helps!

I’ll probably do a write up…after a few more upgrades

@Griff thanks! Beginning able to control the whole process has been really fun. Right now it’s a stock Evo 9 drivetrain but the owner might pull the trigger on a sequential! Only 15k lol.

The nice thing about big turbos is that your TQ hit will be much softer. That combined with driving style and it should actually last a good amount of time.

Chips looks really good btw, awesome feeling from making glitter huh!

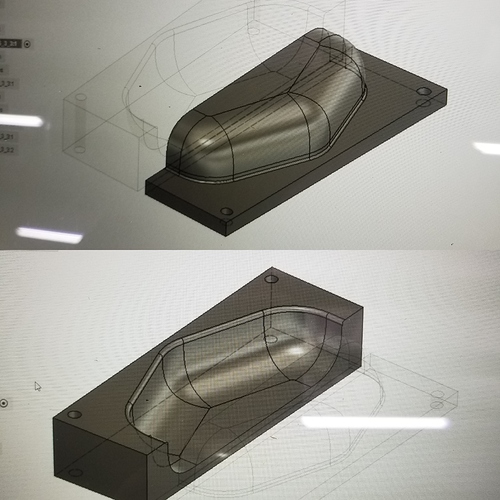

Customer is pulling the trigger on material

Two blocks of 20x6.5x4 for these custom plenum press dies. Starts out something like 60lbs lol

Think I remember you using a linear shaft on your other S3, feel the linear rail makes more difference (even with the less leverage do to mounting locations)?

@DanStory I haven’t really had a chance to truly test the new rail but its worlds above the other in just smoothness.

@RichCournoyer your homemade single flute thread is saving my butt tonight! Thank you for sharing that info sir, four tries to get it right.

Thanks to Ed Kramer and Richard

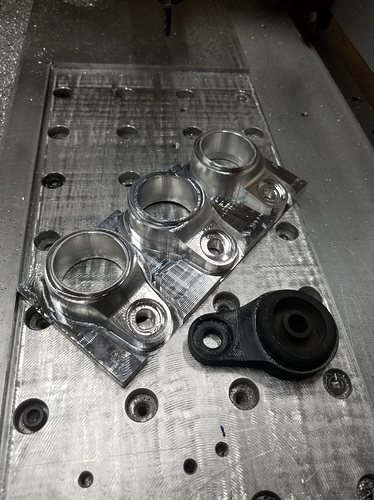

Success on the first shot

On today’s episode of “Things Vince does that shouldn’t work but do”

Homemade single point 0.250 threadmill made from a 1/4-28 hss tap and cnc threadmilling a 3/8-32 thread.

Link to Richards thread on threadmilling https://community.carbide3d.com/t/thread-milling-in-metal-on-the-shapeoko-3/5332

How did you make your switch insert there? Screened? Printed?

( I ask because it looks nice, and that sort of thing is what I do for a living)

That sticker dial face came with the kit, was thinking about engraving but its actually great for indexing.

dont mind me, just trying to embed a vid

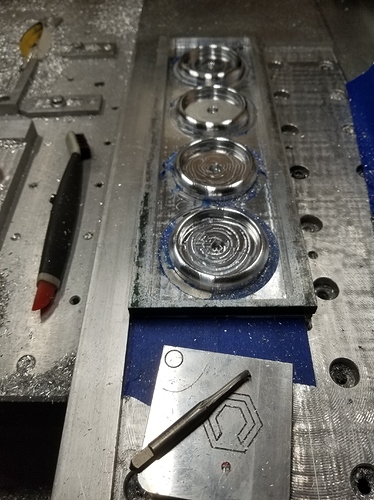

2op only, one endmill.

They weight nothing and fit perfect

Overjoyed

Oh…stubs can cut brass and hardened steel, still going strong. Coating is wearing off but this little guy has been through a lot… and starting on another 3x9.5x1.5 block right now.

Stumbled upon this video, which was really interesting watching him slowly upgrade the OpenBuilds MiniMill to use linear rails, and the difference it made, along with a couple other rigidity improvements:

Really showed the improvements going from [solid] v-wheels to linear rails.

Pretty decent results from his experiments but that chatter was tough to listen to lol. Finally sounds better in the end but the S3 in stock form seems more capable.

Been toying around with building a mini mill

Thanks Dan, I agree that the before/after was very enlightening, that guy did a great job explaining everything.

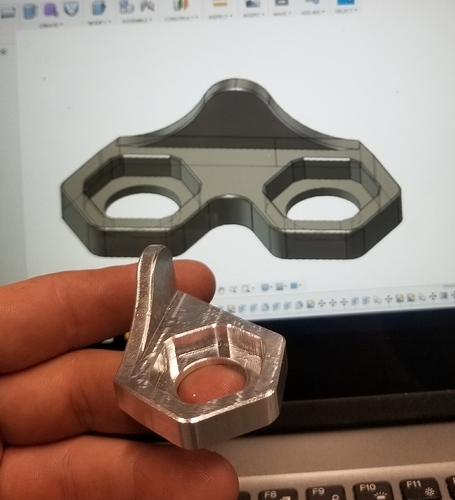

Three sets of radiator brackets done, one set to coating. Next up a little double sensor bracket action

Word on the street, hexy is the new sexy

We all know the shapeoko is never going to be a super precise machine, however in my line of work, having this ability is leaps above most. I’ll be a happy man if I never have to bend sheet metal by hand again!