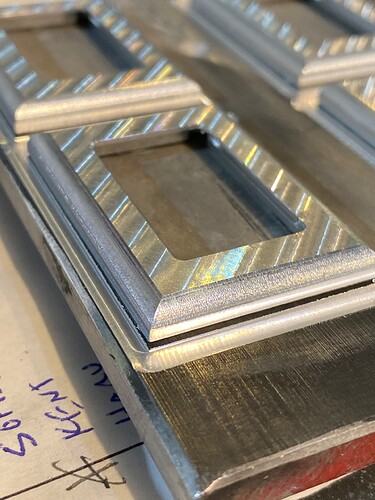

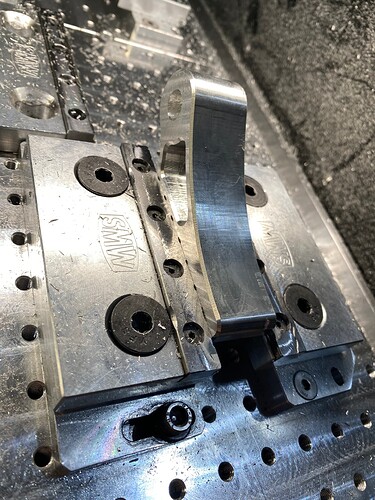

Lots of learning today on parts, but the edge finder is a welcome addition to make 2nd side opps like this easy…

What sort of accuracy and repeatability are you getting with that electronic edge finder?

So far seems dead on, the small window switch trim I used the inside cutout as the X + Y and on the flip there was no edge of material. I work in mm so the dimension of the tip being .2” makes the mm off a sliver, but so far it’s been amazing

Your posts are fantastic! Love the work you do and your parts looks amazing!

It so cool that you keep pushing out Porsche parts of your machine! Keep em coming ! ![]()

![]()

Thank you, I find that sharing also helps me push what we can do

I concur

He must be @Vince.Fab cousin or something ![]()

Bryan’s posts remind me a lot of Vince’s early Shapeoko work

Thank you that is a huge compliment in my books. Vince’s posts made me jump into this because of the need to prototype and build custom parts for our clients. With the HDM now it feels like I went from a Pinto to a PORSCHE in terms of performance and repeatability. And I want to share so others can be inspired, like I was by the great community of people who are showcasing what can be done with some time, learning and lots of fun…

So my enclosure design with chute is working pretty good, need to a seal up the door a bit, but this is what 3 days of chewing they metal collects in the 55 gallon drum barrel under the machine. I have just used air to “push” the shavings to the lower chute thru the open base… I’ll probably add a vibrator to it like I have on my sandblaster to help evacuation but basically it’s working great

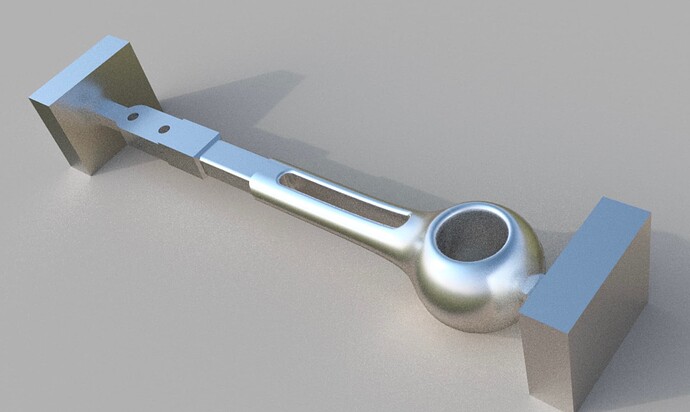

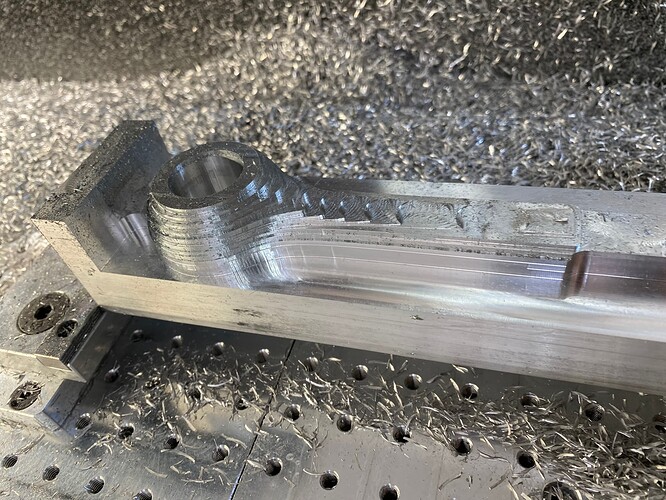

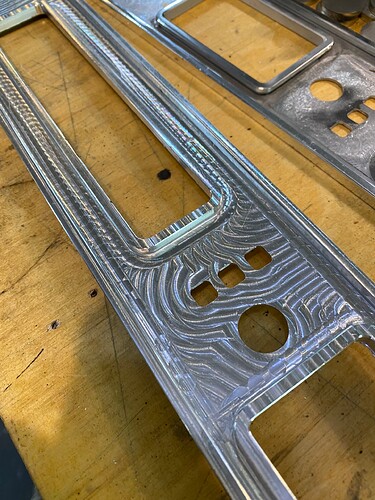

Midnight oil burning tonight, 3 operational flips , my touch probe was dead on with all the flips and alignment… the first rough was about 4 mins to get the profile… insane

Crazy how well the HDM works for testing and prototypes, this new end design match’s the cars mounting point contour vs flat. In 6 minutes the rough was cut using a 3/8 mill… game changer in the shop for sure.

Can you link the probe you are using please I am not willing to drop several hundred on a haimer at this time.

From what I’ve seen, he’s using an electronic edge finder, and it’s this one. https://www.amazon.com/Fowler-Electronic-Edge-Finder/dp/B00B5KS1QE

Yes sorry I was at our rallye for old Porsches all last week in West Virginia, so I am back in the shop now. It is the one you linked too also

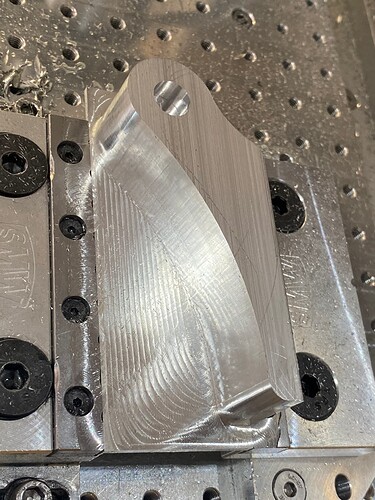

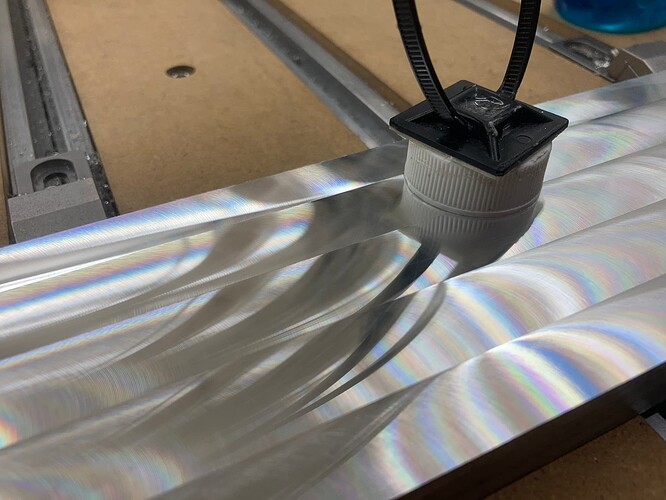

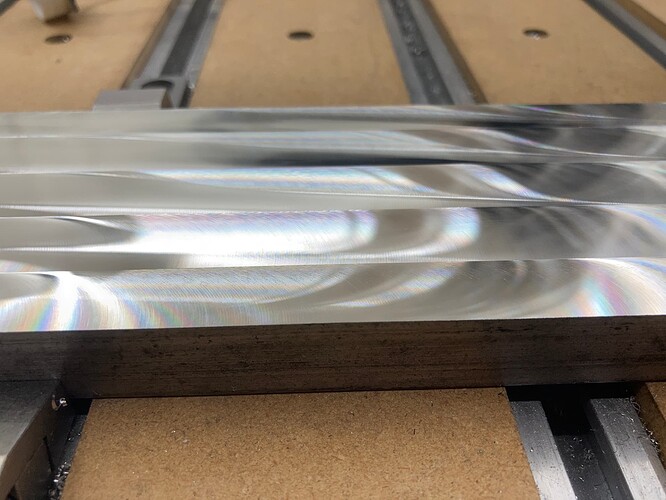

Got the big face mill out today 1” and it allowed me to really tram the HDM in. About 3 layers of aluminum foil on the top and it’s butter smooth… plus it’s fun watching this rip they the material at such a wide pass!

What were your feeds? So far I run 10k 25 ipm .005-.01" for finishing and 40 ipm .005-.03" for roughing 70% stepover.

I haven’t had help to properly tram my spindle so there is a little room left for improvement there.

Abe that looks awesome, I’ve got to look but I believe I’m at 45ipm with a .02 doc. With a 50% step over, I need to optimize a bit and I’ll try yours and 70%

This machine is still amazing me, big CNC results for a decent price. I did this today which was 50% longer run times and way worse finish on the PRO